2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:38

The development of science and technology in the modern world is based on the use of special procedures for the design and modernization of existing structures, progressive methods and approaches in production activities. Integrated solutions that ensure the constant development of the design and technological base of industrial enterprises, as well as their compliance with rational economic use, are called technical preparation of production. It is based on innovative processes occurring in the context of scientific and engineering research (design and technological preparation of production).

Types of studies

Scientific research can significantly increase the level of competitiveness of the developed products. From the point of view of the processes or phenomena to which they are directed, they are considered in the context of three main groups:

- Basic research -make it possible to obtain new laws or patterns of behavior of objects and systems of the surrounding reality, with the aim of further use in the production and economic activities of people. Conducted by special (specialized) research organizations.

- Exploratory research - testing open patterns for production activities, which allows to increase the scientific and technical level and overall efficiency of enterprises and civil sector facilities.

- Applied - in continuation of previous research, they allow solving specific scientific and engineering problems, creating new technologies or designs.

Basic research is usually government funded because it often has no market value. Search and applied research is aimed at solving practical problems and is often financed by commercial enterprises. Scientific research on a specific problem, carried out according to a specific plan, is called a scientific topic (economic-contractual).

As a rule, design pre-production includes certain types of research.

Stages of scientific topic implementation

Economic-contractual, that is, financed by individual enterprises, and scientific research is carried out according to a certain traditional scheme:

- development of terms of reference for the problem to be solved and feasibility study of the proposed topic;

- selection of research direction, which is based onstudying existing solutions, researching patent information, and developing general implementation guidelines;

- conducting research (theoretical and experimental) to determine the theoretical positions of real data obtained from the experiment;

- general conclusions on the work done and the preparation of a report.

The results obtained are the basis for further stages of design preparation for production. An industrial enterprise that has developed departments for the design and development of new technologies (chief designer, chief technologist) in its organizational structure can independently conduct these studies. If necessary, it is possible to attract external research organizations (institutions, venture firms), which makes it possible to increase the complexity of the work performed and speed up the pace of individual stages.

Conducted research (innovative processes) allows you to get three main types of innovations - discovery, invention and rationalization proposal. Their introduction into production and economic activities is an important element of the technical development of enterprises over time and is one of the key elements in the organization of design and technological preparation of production.

General issues of the organization

In the process of functioning, industrial enterprises need constant restoration of industrial buildings, technological equipment andinfrastructure elements (traffic flows, engineering networks, communications, etc.) due to physical deterioration. In addition, it is necessary to ensure the development of the technology and technology of the enterprise to meet the new economic conditions and the increasing requirements of consumers. Which is the main purpose of design pre-production.

The actual level of the technical condition of the enterprise must be assessed at specified intervals, taking into account a number of indicators of the production system. They are evaluated in the dynamics of change over time both at the enterprise itself and in related systems, which makes it possible to rationally correct them. It should be noted that the control of enterprise funds and their maintenance in working condition is the main task of the activity of infrastructure facilities of enterprises.

Development assessment parameters

As a rule, indicators are considered according to certain criteria:

- The level of technical equipment - how production workers are provided with the necessary funds (funds) and the necessary energy resources.

- Degree of novelty of technologies - proportional distribution of processes by labor intensity, the percentage of new technological processes and techniques, the average age of the elements of the applied technology, the rationality of the use of materials and spare parts.

- Novelty and conformity of equipment characteristics - performance parameters, functionality, material consumption, reliability indicators (reliability, durability, maintainability andsafety), the average duration of operation, the percentage of progressive equipment, the percentage of equipment that is physically and morally worn out.

- Indicators of mechanization (automation) - the number of mechanized labor operations; percentage of products manufactured using automated devices (technologies).

The system of design preparation of production allows you to maintain the value of these indicators within the established limits.

Technological development directions

To solve urgent problems of maintaining and improving production systems over time, various mechanisms and procedures for influencing elements of the enterprise are used. For their implementation, the approaches of design preparation of production are involved. These destinations include:

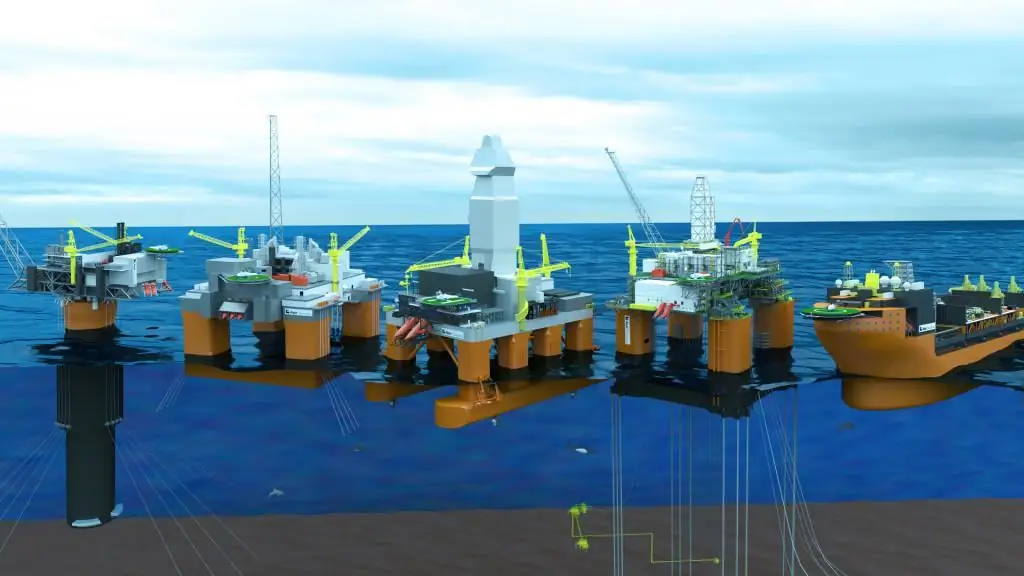

- Construction of new facilities - building an enterprise from scratch, creating a new production unit (workshop, site) in the manner prescribed by law.

- Increasing the scale of the existing enterprise - the introduction of additional capacities of the enterprise through the creation of additional divisions or facilities; increasing the footprint of existing units to improve production performance, capacity for increased product flows and cost efficiency.

- Reconstruction - change of individual subsystems of the enterprise, improvement of technological and technical structures. It is carried out on the basis of replacing obsolete technological equipment, increasing the sharemechanized (automated) processes, elimination of disproportion in the work of various subsystems of the enterprise (which contributes to the improvement of the macroeconomic indicators of the enterprise).

- Re-equipment or re-equipment of means of production - replacement of obsolete equipment and tools with more advanced ones with improved performance.

- Modernization - individual improvements in the elements of the production system (equipment, technology, organization and control) to match production and created products (elements, systems) to changing market conditions, standards or consumer requirements.

In addition to these indicators, production systems are evaluated by their environmental impact. They consider the scale of recycling of production waste, pollution of the natural environment, the percentage of environmentally friendly products.

Organization of design preparation of production

Research work in the field of designing advanced structures is a laborious, large-scale and demanding process in terms of the use of material and financial resources, combining the results of designing new products with subsequent experimental evaluation. They are carried out under the control of the OGK (department of the chief designer) or the design bureau (KB) of the technical department of the enterprise.

As a result of ongoing developments, various parameters of production systems are improved - productivity and functionality are increased, cost is optimized, production time intervals are changed andconditions for the most efficient operation of production units.

An important role in the organization of design preparation of production is given to the design departments of the enterprise. A certain order of storage of drawings, plans and diagrams is established. Mechanisms are being developed to provide them to production units in a timely manner. Strict design and technological discipline is maintained.

Problems of design preparation of production

The basic questions that are solved when designing simple and complex systems are:

- analysis of technical conditions for structural elements that are reflected in the features of manufacturing and repair;

- development of various projects for the products in question, with the aim of improving the overall design schemes;

- development of repair tolerances (increasing the interchangeability of parts and reducing production costs);

- improvement and modernization of the element base;

- unification of assemblies (assemblies, parts) to eliminate unreasonable overestimation of the number of standard sizes.

As you can see, the use of design pre-production directly affects the level of losses during the subsequent operation of facilities.

Proceedings

The content of design studies is determined by the characteristic features of the object of study, its functional purpose and method of manufacture (repair). In general, there are sever altypical stages, the result of which will be the creation of regulatory and technical documentation. They are carried out according to ESKD. The complexity of the product and the scope of its further use has a direct impact on the content and number of stages. So, some of them, especially the preparatory stages, may be reduced, combined or completely absent.

Stages of design pre-production:

- Drawing up the terms of reference (abbreviated TK). Drawing up a list of references, analysis of special literature and regulatory documents - instructions, orders, explanations and recommendations. Analysis and subsequent approval of the items of the assignment for the design of the structure. Development of a schedule of proposed work in the form of an algorithmic model (Gantt charts or network charts). Accounting for future design costs. Preliminary calculation of the economic effect from the results of innovation activity.

- Development of a technical proposal (similar to TP). Full calculation of economic components. Considering design options and choosing the most optimal one. Adjustment of the total number of works and the duration of the execution.

- Implementation of a draft design. Consideration of schematic diagrams of new designs or processes, carrying out preliminary mathematical calculations, determining the overall dimensions of the product on the general drawings, making a layout and testing it;

- Technical design. The most time-consuming and lengthy stage of research. Carrying out basic calculations for structural strength, reliabilityand security. Prototype testing (forced and/or accelerated). Modernization of the structure based on the calculated parameters. The most time-consuming, lengthy and expensive stage.

- Preparation of working documentation - creation of assembly drawings, detailing of the product, drawing up schematic and wiring diagrams. Creation of duplicates and copies of documentation. Final design.

The design pre-production stages allow you to complete the full cycle of development and implementation of project documentation.

Features of modern design

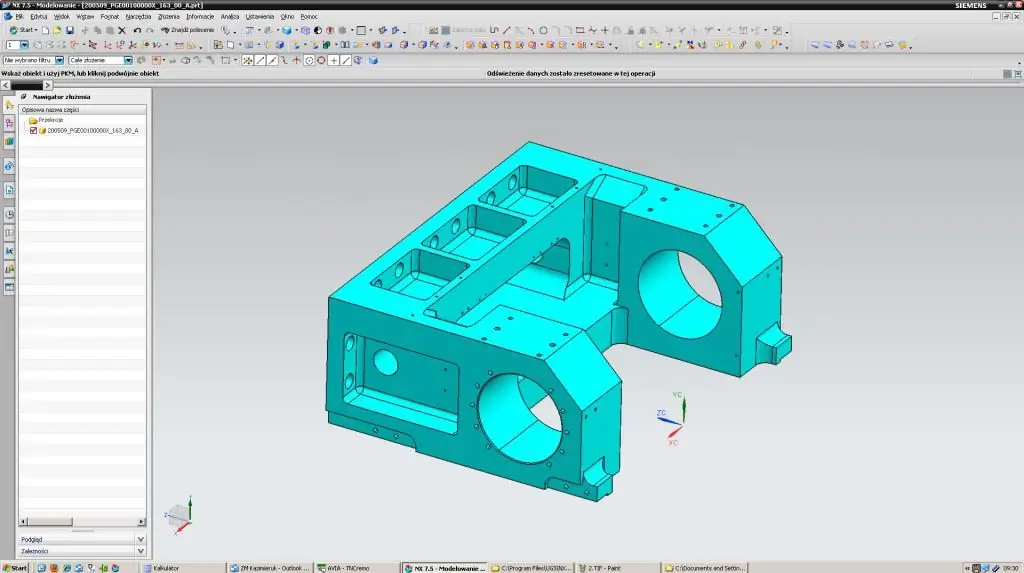

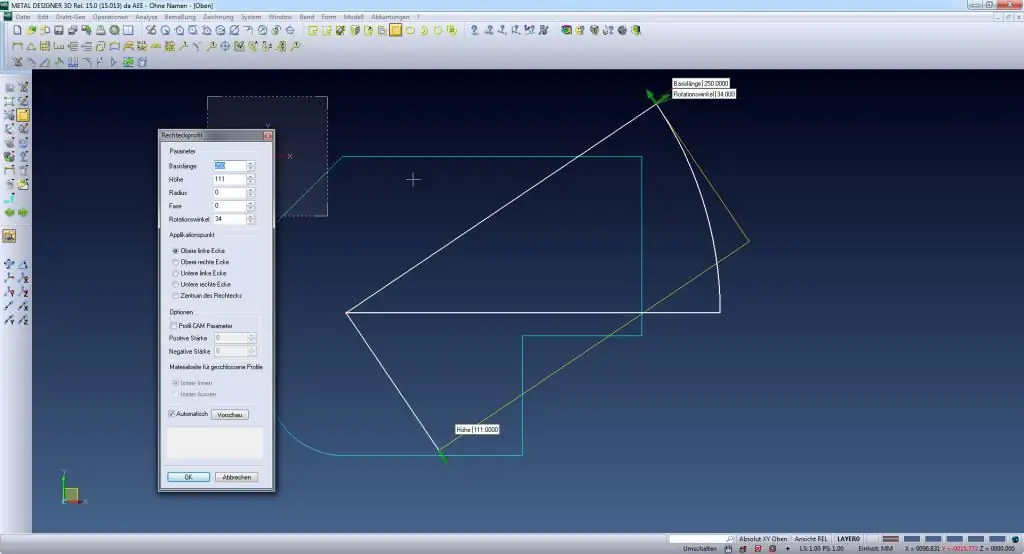

In order to meet the ever-increasing requirements for the element base of structures in terms of reliability and functionality of industrial products, in recent years, design preparation for production has been using computer-aided design systems. Given the increased complexity of individual projects (for example, the development of integrated circuits), the use of special machine methods is often the only possible way to create the required product with given parameters.

When automating design processes, a product is created on the basis of precise machine algorithms embedded in specialized software packages. This reduces the influence of the human factor on the accuracy of calculations and the choice of the most appropriate design option. Significantly reduces the time of project execution, testing and total costs at all stages of design.

Design-design preparation of production at the same time has a number of advantages, which are expressed in the following factors:

- significantly reduces the complexity and duration of the project;

- payroll costs are being reduced (due to staff optimization);

- increases the quality level of the finished product;

- Reliability indicators are normalizing;

- accumulate proven solutions in industry databases;

- documentation is constantly monitored;

- mathematical modeling minimizes non-optimal designs, etc.

Conclusion

The system of design preparation for production is a necessary link in the chain of the life cycle of any product. It is used with equal success both for the creation of industrial products and complex specialized systems. As the experience of recent years shows, the ever-increasing informatization of production processes also puts forward new requirements for the improvement of design systems.

Recommended:

Strategic control: tasks, stages and evaluation criteria

Strategic control is aimed at ensuring the effective functioning of the organization in the surrounding business environment and progress towards the achievement of the strategic goal. Because management research is still in its early stages, especially in the area of strategic control, there are no generally accepted models or theories. In general, the implementation of the strategy requires structure, leadership, technology, human resources, information and control systems

Smoking shop: preparation of necessary documents, drawing up a business plan, selection of necessary equipment, goals and stages of development

The article deals with such a business as a smoke shop. Learn how to start a business and where to start. About how to choose equipment and how it should be. About what you need to pay attention to when choosing suppliers, and about the process of producing smoked products

Advertising agency: how to open, where to start, preparation of necessary documents, drawing up a business plan, goals, objectives and stages of development

Demand for advertising services is strong throughout the year, regardless of the fact that the market is represented by a huge number of companies offering such services. Therefore, when planning how to open an advertising agency, special attention should be paid to market analysis. This will allow you to assess the real prospects of the niche, as well as create an effective business model with high profitability

Project planning is Stages and features of the process, development and preparation of a plan

During planning, qualitative and quantitative decisions are made to achieve the goals of the organization in the long term. Moreover, in the course of such work, it is possible to determine precisely the optimal paths. Project planning is the elaboration of a precise scheme according to which the development of the organization will be carried out. This allows you to think through all the details, choose ways to solve problems and achieve your goals. How such work is carried out will be discussed below

Technical preparation of production: tasks, stages, process and management

The development of new, highly efficient and more advanced products, competitiveness in the world market - all this is directly related to organizational issues, among which a special place is occupied by the technical preparation of production. Why does she have such a role?