2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

The development of new, highly efficient and more advanced products, competitiveness in the world market - all this is directly related to organizational issues, among which a special place is occupied by the technical preparation of production. Why does she have such a role?

General information

A wide range of work is covered: scientific, technological, design, production and economic activities, which allow you to create, master and introduce new developments. This whole area is regulated by a number of standards. Technical training consists of design and technological components. It is carried out according to the plan available at the enterprise.

What does the technical preparation of production include?

It touches on several areas. At the same time, attention should be paid to the organizational and technical preparation of production, the material base, the approach to labor performance of duties andmanagement processes. For simplicity, it's better to represent it as a list:

- Applied research in progress.

- New products are being designed and previously created ones are being modernized.

- The technological process of product creation is being developed.

- Special equipment, tools and accessories are purchased.

- Manufacturing logistics requirements secured.

- Staff are being trained and the qualifications of existing ones are being improved.

- Technical regulations being developed.

- Information support is being organized.

All this is carried out in order to effectively master the production of a new product, the introduction of new equipment and machines, technological methods of conducting production. The tasks to be performed also include the creation of the necessary conditions. At the same time, it is necessary to solve technical, organizational and economic issues. All this allows you to take the production process to a higher level, using the achievements of science.

Planning

Organization of technical preparation of production includes design and technological work. Which stages will be identified depends on the type of enterprise, its profile and scale. Technical preparation of production always acts as an object of in-plant planning. At the same time, detailing of a certain level and active specification of the position are provided.

Developing plans is an integral part of a long andmedium term planning. In the first case, it is necessary to determine the main directions, as well as the stages of technical training, when it begins and ends, a breakdown is made by type of work, objects and sources of funding, specific performers.

In the medium term, one of the above is considered that should be completed during the current / future planned year. As the initial data, the task of the plan, the standards for a certain volume and scope of work, as well as their duration are used.

Regulations used

When it is only planned to organize the technical preparation of production, a large role is given to standards. Among them, it is necessary to distinguish between voluminous, labor-intensive, in kind.

Regulations have a local character. This is due to the fact that their development requires analysis and generalization of reporting data. Moreover, it is necessary to understand that for a particular enterprise, it is necessary to take into account the specifics of its functioning, as well as the economic condition. For example, volumetric standards make it possible to focus on the number of technological operations, the number of technical and drawing documentation, original parts, and to assess the complexity of their manufacture. This approach makes it possible to reflect the design experience as a whole throughout the industry, allied enterprises and competitors. But in practice, there are often issues of reducing the deadlines.

About the methodology

How is the need for acceleration solvedenvisaged processes? To achieve this goal, the method of parallel-sequential work is used. What does such an approach imply? For example, it may be envisaged that the work of the second stage begins even before the first is completed. As a result of the decision, when the stages of technical preparation of production are reduced, the duration of the entire cycle is also reduced.

The use of visual network graphs also plays a big role. For their formation, two types of elements are used: events and works. And they are closely related. So events indicate the beginning / end of a certain type of work. They can be clearly fixed at the first and last stages.

The notion of initiating events is used to denote the start of the first work. The duration of the actions performed is indicated by the number of units of time. Usually specified in days or months. It is also necessary to indicate the costs of the work carried out. This is usually done in currency units and man-days.

A network diagram is used to have an idea of the completion of certain events with sufficient accuracy. In addition, they allow you to optimize the timing, identify and determine the influence of various factors, organize monitoring, management and control over the actions of individual performers.

About standardization

The process of technical preparation of production is very dependent on the use of norms, compliance with rules and requirements. Standardization creates favorable conditions for activity. This is especially true ifwe are talking about the scientific and technical preparation of production at the highest level, which will allow us to produce products that can compete in terms of quality.

Example

To better understand the above information, let's look at what technical and technological preparation of production is from beginning to end. Let's go through the entire set of interrelated works that determine the sequence of the production process in the most rational ways. The main goal pursued is to achieve high quality of the created products, create conditions for the reasonable organization of production processes, and improve the equipment used.

Getting Started

The prepared documentation must comply with the unified system of technological documentation. So, you need to make sure that:

- Analysis of working documentation was carried out, as well as control of the design of units and parts.

- The information received was corrected regarding the specific conditions for the manufacture of products within a particular enterprise.

- Progressive technological processes for the production of parts, their assembly, adjustment and subsequent testing of individual components and the entire product were developed.

- Required tooling and non-standard equipment were designed.

- Developed and implemented rational methods of technical control.

- Adequate technological routes were created and, inaccording to them, the layout of workshops and production sites.

- Introduced and improved workplace processes.

- The production capacities of the enterprise, the consumption rates of tools, materials, energy resources and so on were calculated.

What work is being done?

When the design process is underway, care must be taken that numerous conditions are aimed at achieving a high level of manufacturability already at the first stages of product creation. So, when a prototype is created, it already makes sense to think about pre-production. But the main work still needs to be carried out after all the design documentation has been received.

Typification and standardization should be based on the classification of objects, the choice of a sample and the creation of a unified process. It should be remembered that the service life of the resulting product largely depends on the quality. For this, electronic computers are widely used. Moreover, both at the stage of design and creation. And all this should be documented. After all, papers are used not only for the manufacture of products and operational management, but also for setting time standards, standards for the consumption of materials and energy resources.

Refining processes

When the technical preparation of construction production or any other creative activity is carried out, technologists must establish weaknesses. At the same time, you need to make sure that there are no problemsthe following functional components work:

- Communication with the logistics department has been set up regarding the readiness for the supply of materials.

- The schedule for the technological preparation of production for the workshops of the enterprise (construction site) is being established.

- Economic evaluation and process selection in progress.

- Manufacture and creation of backlogs are planned.

- A schedule is being drawn up for the commissioning of the necessary equipment.

- Create cutting charts used to calculate material standards.

- Carry out accounting, storage, reproduction and issuance of the necessary technical documentation.

Comparing the received technological costs and capital costs for different technologies, they choose the best option for the implementation of the process and determine the critical level of the production program of the enterprise (break-even point).

On management issues

A complex process always requires guidance. Management of the technical preparation of production should be at any stage, from the design stage to the industrial basis of the manufacturing process of new products. That is, management means a set of measures that should provide production with everything necessary.

In addition, it is necessary to address the issues of planning, as well as organization. The task of managers is to determinethe need for additional workforce, equipment, fuel and energy and material resources. You also have to ensure the availability of the necessary equipment, tools, fixtures.

The leadership is also responsible for solving issues of specialization and cooperation of workshops, maintenance of jobs, organization of tool, repair, storage and transport facilities. It also approves the necessary labor, material, calendar-planning and financial standards. We have to solve the issues of managing the production itself, to form a motivating system of remuneration.

Conclusion

Let's briefly go over the above. Technical preparation of production consists of the following stages:

- Design.

- Technological.

- Organizational and economic.

- Industrial development of new products.

They are all closely related. It is necessary to ensure that after their implementation a rationally tuned process of creating certain material values \u200b\u200bthat has a competitive quality in relation to the samples presented on the market is obtained.

Recommended:

Project planning is Stages and features of the process, development and preparation of a plan

During planning, qualitative and quantitative decisions are made to achieve the goals of the organization in the long term. Moreover, in the course of such work, it is possible to determine precisely the optimal paths. Project planning is the elaboration of a precise scheme according to which the development of the organization will be carried out. This allows you to think through all the details, choose ways to solve problems and achieve your goals. How such work is carried out will be discussed below

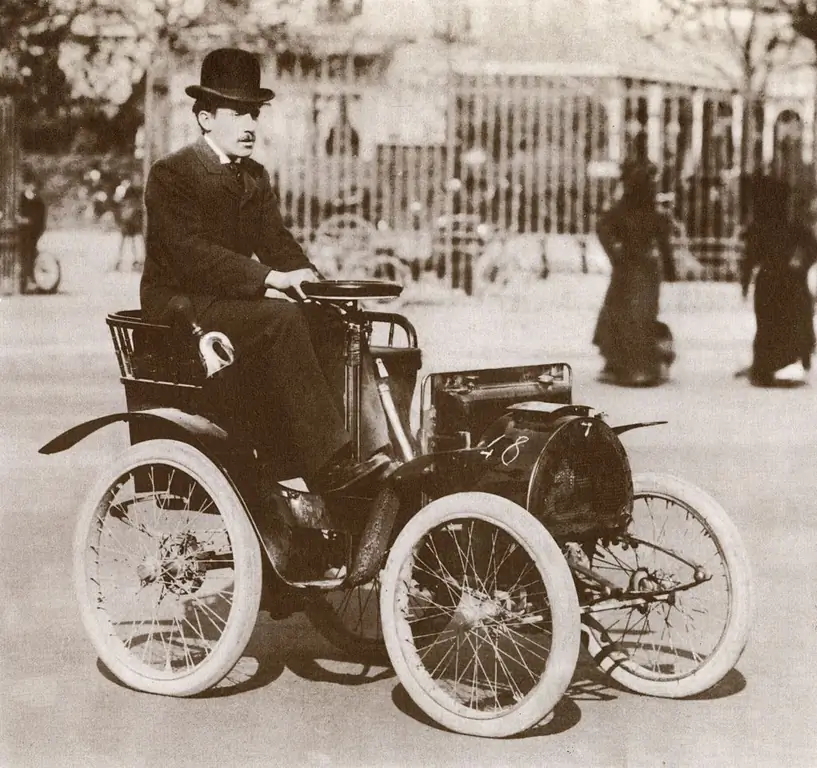

"Renault": manufacturer, history and date of creation, management, country, technical focus, development stages, introduction of modern technologies and car quality

The Renault manufacturer produces high-quality cars that are in demand in many countries of the world. The products were to the taste of Russian motorists. In 2015, the French concern produced the millionth car from the lines of the Russian plant

Design preparation of production: stages, tasks and purpose

To match the production system to changing environmental conditions, the mechanism of technical preparation of production is used. The development of new designs of products or production elements is ensured by the integrated use of design and technological components

Vitamin plant in Ufa: history and date of establishment, management, addresses, technical focus, stages of development, introduction of modern technologies and product quality

The life of a modern person takes place in a rather unfavorable ecological environment, accompanied by intellectual and emotional overload. You can't do without taking vitamins and minerals even in the summer. This material will focus on one of the oldest enterprises in Ufa, which is engaged in the production of useful products

Irkutsk heavy engineering plant: history and date of establishment, address, management, technical focus, stages of development, introduction of modern technologies and quality

Irkutsk heavy engineering plant is a city-forming enterprise producing equipment for leading industries in Russia. The company's products are supplied to the domestic market, finds recognition and demand abroad