2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

Liquid glass, stationery glue - the materials are well known to us, since they are widely used in everyday life. But, perhaps, our information about them is very limited, but meanwhile, learning about soluble potassium silicate, which serves as the basis for their manufacture, is not only interesting, but also useful. Here's why.

Few people have heard that potassium silicates are associated with such a concept as "dangerous preservatives." Indeed, how can people who are not associated with chemical production know that they are an E560 food additive that prevents clumping and caking. They are used in baking, production of granulated sugar, powdered milk and other powdered food products, as well as in pharmaceuticals and cosmetics in the manufacture of powders and gels. It is impossible to say unequivocally that potassium silicate (formula Na2O (SiO2) n) is a dangerous preservative, since the permissible daily intake has not been determined. In the Russian Federation, the additive is allowed, despite the fact that it has not yet passed the necessary tests and tests. This should be known andtake into account in daily life.

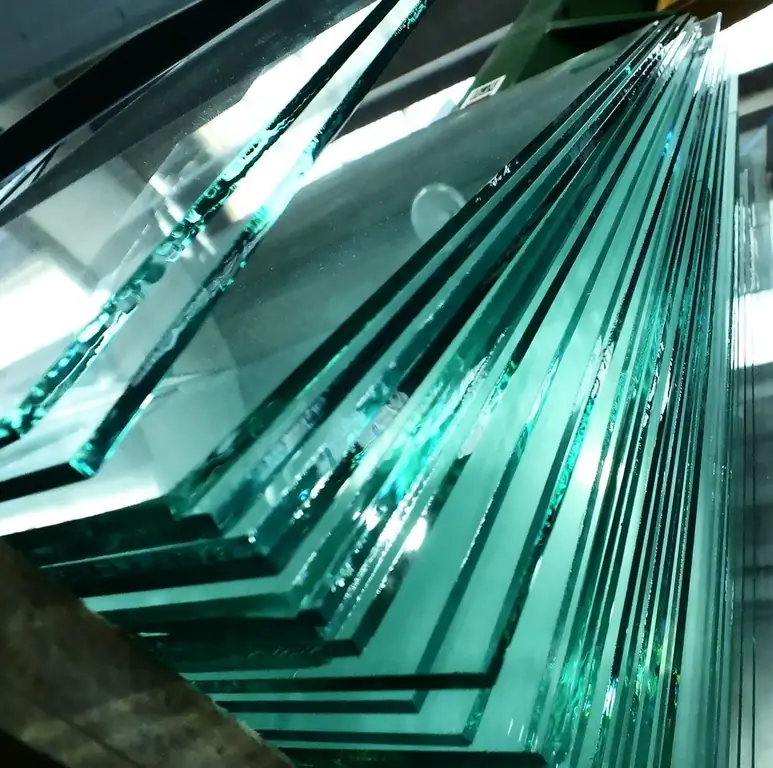

And now let's talk about liquid glass, as the most well-known material based on potassium silicate. The manufacturing technology is rather complicated, so the production of silicate blocks is the absolute prerogative of chemical plants. In short, the essence of the process is that the combination of fine quartz sand with soda is fired in a furnace at a very high temperature, then the potassium silicate obtained in the form of a lump is crushed, and only then can an aqueous solution be obtained from it. In view of the fact that potash, which has a high cost, is also used as a raw material in the production of potassium silicate lumps, potassium silicate, unlike sodium silicate, has not found mass application. In 90%, sodium silicate or its mixture with potassium silicate is used to obtain liquid glass.

The liquid composition based on potassium silicate is indifferent to acids and has a high resistance to weathering. The surface treated with potassium glass does not give glare, so it is often used in the production of various types of paints, and a few years ago, liquid glass began to be used to make automotive polishes. In construction, potassium glass is used as impregnations and additives - adding it to cement mortars, putties and plasters can increase their strength and insulation characteristics.

Flame retardant paints containing potassium silicate are an excellent coating for public wallspremises. Surface treatment with mixtures with the addition of liquid glass gives them anti-corrosion and waterproofing properties, resistance to high temperatures. In the chemical industry, this substance is involved in the production of sodium metasilicate, silica gel solid adsorbent and lead silicate. In ferrous metallurgy, it is used for the manufacture of molds, in foundry - as a flotation agent. Recall that the well-known stationery adhesive also contains potassium / sodium silicate and is used to bond glass, wood, metal and paper.

Reminder: Liquid glass, although not a toxic substance, still requires careful handling. If product comes into contact with skin or eyes, rinse immediately with plenty of warm water.

Recommended:

How to make glass? Glass production technology. glass products

Glass is familiar to everyone. But the process of making it is extremely exciting. Each stage is important and affects the quality of the final product. The basis is sand, soda, lime. The process is almost entirely automated. Surprisingly, glass can even be made at home

Silicate glass: production and use

Silicate glass is a common, affordable material for use in various areas of production, everyday life, and industry. It is made from natural ingredients and has a large number of positive properties

Common stock is Bond and common stock

An ordinary share is a share that gives the right to own the property of the issuing enterprise. Their holders can elect members of the board of directors and influence key issues, take part in the regulation of the organization's income (through dividends)

Silane Guard - liquid glass: reviews and method of application

Do you want your car to look like new? Now for this purpose it does not need to be taken to a car service. Polishing machine surfaces at home is the use of a novelty - Silane Guard liquid glass. Consider the features of this substance, study consumer reviews

Common property of an apartment building - what is it? Maintenance and repair of the common property of an apartment building

The legislation of the Russian Federation adequately regulates in detail the procedure for the use of common house property by apartment owners. What are the key provisions of the relevant rules of law?