2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

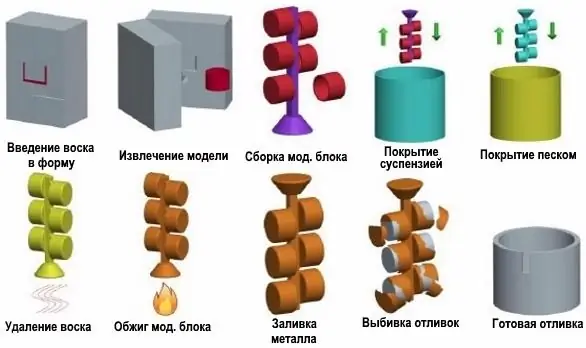

The use of investment models is a fairly popular method of foundry production. The method is distinguished by the complexity of the technological process and high labor costs for preparatory processes. Therefore, it is used where it is necessary to accurately observe the dimensions and ensure high quality of the surface of the parts. This is how turbine blades and high-performance tools, dentures and jewelry are cast, as well as sculptures of complex configuration. The essence of lost-wax casting is that the mold for casting is one-piece, the model of low-melting materials is not removed during molding, but is melted. This ensures careful observance of dimensions and relief. Metal is poured into the cavity remaining from the model. Upon completion of cooling, the mold is destroyed and the product is removed. When casting large series, the cost of the product is reduced.

Method advantages

The main advantage of investment casting is the accuracy of mold transfer and low surface roughness. In addition, other benefits are available:

- Production of lightly machined alloy parts available.

- Reduces the need for further machining.

- Products are cast that otherwise would have to be made in parts and assembled together.

- With large series, a reduction in specific labor intensity (per one product) and its cost is achieved.

- Possibility of mechanization and partial automation of the preparatory operations of the casting itself.

These advantages make the method one of the most popular and used in today's metallurgy, especially in combination with modern progressive casting methods.

Disadvantages of investment casting

The undoubted advantages of the method, it would seem, should have ensured its dominance among other methods. However, despite the popularity of the investment casting method, disadvantages have prevented its widespread adoption. The main disadvantage is the complexity of the multi-stage process. It requires quite complex and expensive technological equipment for the preparatory stages. For simple products produced in small batches, this method has a higher cost.

For the cost-effective application of investment casting, the advantages and disadvantages of the method are compared, the decision onits choice is taken on the basis of an assessment of the price / quality ratio. Therefore, it is mainly used for the most critical and expensive products that are difficult to obtain in any other way, such as turbine blades, sculptures, high-speed tools, etc. Another area of application is large-scale castings, in which the scale effect makes it possible to achieve a significant cost reduction.

Technology

Investment casting technology is a multi-stage manufacturing process that is relatively labor intensive. At the first stage, a master model is made, it will become the standard for the manufacture of working models after passing through all the stages of the final product. For the production of a master model, both special model compositions and traditional ones - gypsum or wood - are used. The material of the master model should combine strength and ease of processing.

Further, investment casting technology provides for the creation of a mold into which all working models will be cast. Molds are made of gypsum, rubber, silicone, less often metal. Structurally, it must necessarily be detachable and designed for repeated use. The mold is filled with a model composition, after it has hardened, it is disassembled and the next working model is removed.

When producing unique parts or small runs, the stages of creating a master layout and a mold are skipped, and a layout (or several) is made by molding the material manually.

The next step in the investment casting process ismanufacturing around the layout (or block of layouts) of the casting mold. These matrices are structurally already non-separable and disposable, which makes it possible to achieve careful observance of the dimensions and roughness of the product. In modern industry, two types of molds are used - traditional sand-clay molds for casting into the ground and shell molds - for the production of precise and expensive parts.

After the mold is completed, the model is smelted from it by heating or blowing with superheated steam. Shell molds are additionally strengthened by heating up to 1000 ˚С.

The final stage of the process includes the actual casting of the product, its cooling in natural conditions or by a special method in a thermostat, destruction of the mold and cleaning of the product. The method allows to obtain high-quality castings weighing from several grams to tens of kilograms.

Model Lineups

The material for the production of the layout must have certain properties. It should have properties like:

- Plasticity in the solid phase. It is necessary to accurately repeat the shape of the future product and correct it if necessary.

- Strength. The model must withstand without deformation the process of forming a shape around it.

- Fusible. Rendering a model should not require a lot of time and energy.

- Molten fluidity. The composition should easily penetrate into all the recesses and details of the relief, exactly repeating the outlines of the future detail.

- Economy. Particularly important for large series production.

For model compositions, a mixture of stearin and paraffin is usually used. These materials successfully complement each other's parameters, compensating for the insufficient melting point of paraffin and the excessive viscosity of stearin.

Compositions based on lignite wax are no less popular in the industry. Its main properties are moisture resistance, strength and the ability to form very smooth coatings, which is especially valuable for product modeling.

Compounds consisting of a mixture of brown coal wax, paraffin and stearin are also used.

Mold making

For the production of unique products, a layout is prepared by cutting out a piece of model material manually or according to templates. Models in the form of bodies of revolution are also made on lathes. Recently, the method of 3D printing of models has become more and more widespread. It is suitable for both single layouts and small series.

The cost of a modern industrial 3D printer is still high, but due to the ease of reconfiguration from one product to another, it can become an effective model making tool in case of a large number of heterogeneous small series orders.

In order to make a large number of identical layouts, a matrix is made of plaster, rubber, silicone or metal. Working layouts are produced, in turn, by casting into a matrix. By design, the mold must be collapsible to ensure the possibility of manufacturing a given number of models. The selected material should also provide such an opportunity, therefore, such requirements are imposed on it as strength, density, low roughness, and chemical inertness in relation to the layout. The mold substance must also have minimal adhesion to the mock-up to ensure that the finished mock-ups can be easily removed and dimensions adhered to. An important property of the mold is its strength and wear resistance, especially for large series.

Making models and blocks

A widely used method of manufacturing investment models is casting them under low pressure into molds. The injection of the liquid mixture is carried out both manually, using piston syringes, and mechanical, hydraulic or pneumatic superchargers. In the case of using brown coal wax, it is necessary to heat the pipelines for supplying the composition due to its high viscosity. Expanded polystyrene models are made by extrusion on automated molding machines.

To increase economic efficiency and reduce labor intensity in the case of serial production of small castings, their layouts are combined into blocks. Gating systems are formed above the blocks by attaching individual layouts to the sprues using a hand soldering iron. In the case of single castings or small series, the models are made by hand.

When forming gating systems, it is necessary to ensure non-turbulent flow of the melt, uniform filling of all elements of the matrix. When stuffing a form from PGS, you must also monitor the uniform filling of allopenings between sprues and preventing damage.

Making a mold

In the investment casting method under consideration, there are two main types of molds:

- Sand-clay mixtures (SGM).

- Shell.

Food casting molds made of PGS are mainly used in the production of small series of products that do not require very high precision. The process of their manufacture is quite laborious and requires high and often unique qualifications of modelers and moulders. Partial mechanization lends itself only to certain operations, such as preparing and filling the molding sand, its tamping.

Shell molds, on the other hand, are used to produce parts that require special manufacturing precision. The process of their manufacture is more complex and lengthy, but it lends itself better to mechanization.

Ground casting

This is the earliest method of metal processing mastered by mankind. It was mastered by our ancestors simultaneously with the beginning of the use of metal products as weapons, tools or utensils, that is, about 5 thousand years ago. Molten metal is poured into a prepared matrix from a mixture of sand and clay. The earliest places for metal processing just arose where deposits of metals in the form of nuggets and placers were located nearby. A typical example is the Kasli Plant in the Urals, world famous for its iron lace casting.

The investment casting method is used for the manufacture of metal products - both ferrous andcolored. And only for metals that exhibit an increased tendency to react in the liquid phase (such as titanium), it is necessary to make matrices from other compositions.

The production process of casting in PGS consists of the following phases:

- model making;

- preparing the flask;

- filling and compaction of the mixture in the flask;

- metal casting;

- removing and cleaning the casting.

Form from ASG - single use. To get the finished product, it will have to be broken. At the same time, most of the mixture is available for reuse.

Compositions of predominantly quartz sands of various grain sizes and plastic clays, the content of which ranges from 3 to 45 percent, are used as materials for ASG. So, for example, art castings are produced using a mixture with a 10-20% clay content, for especially large castings, the clay content is adjusted to 25%.

Two subtypes are used:

- Facing mixtures. They are located on the inner surface of the mold and interact with the molten metal. They must be heat-resistant, capable of not being destroyed by temperature differences and the resulting stresses. These mixtures have a fine grain to carefully convey the details of the surface. The ability of the mixture to pass gas is also very significant.

- Filling mixtures. They are used for backfilling between the facing layer and the walls of the flask. They must withstand the weight of the poured metal, retain the shape of the product and contribute to the timely and complete removal of gases. Produced from cheaper grades of sand,reusable.

If the casting gases do not escape through the masses of the molding sand, but through the gating system, defects occur in the casting, leading to marriage.

The traditional technology of casting into the ground is illustrated in detail in A. Tarkovsky's film "Andrei Rublev". In the short story "The Bell", the young man Boriska, the son of a deceased master, heads a foundry artel and casts a church bell.

Shell casting

The method of investment casting in shell molds is characterized by the best transfer of product dimensions and low surface roughness. The model is made from fusible compounds, such as brown coal wax. Foundries also widely use the composition of paraffin-stearin in equal proportions. In the case of castings of large sizes, s alts are included in the model material to protect the model from deformation. By dipping into the solution, the model is covered in 6-10 layers with a high-temperature suspension.

Hydrolyzed silicates act as a binder, electrocorundum or quartz crystals are taken as a heat-resistant sprinkling. Shell mold materials are characterized by high strength, low hygroscopicity and excellent gas permeability.

The layout is dried in an atmosphere of gaseous ammonia. At the next stage, the mold is heated to 120 ˚C to remove the paraffin model. The remains of the mixture are removed with superheated steam under high pressure. Next, the mold is calcined at temperatures up to 1000 ˚С, which leads to its final fixation and removal of substances,which may be released as gases during the casting process.

The shell is placed in a kind of flask, which is covered with steel shot. This helps to maintain the configuration when filling the mold with melt and at the same time improves the conditions for cooling the casting. The melt is poured into molds heated to 1000 ˚С. After cooling the product according to a special program in a thermostat, the mold is destroyed, the casting is removed and cleaned.

The main advantage of this casting method is its high dimensional accuracy and low surface roughness.

Additional advantages of the method:

- Casting parts from alloys that are difficult to machine.

- Casting items that would otherwise have to be cast piecemeal and then put back together.

The disadvantages of this investment casting method are low metal utilization and increased labor intensity.

Precision casting

Precision investment casting - this is how both the technology and the final product itself are called. The high accuracy of casting is ensured by the fact that during the preparation of the mold there is no need to extract the model of the product from it. When using the traditional method, the production of a casting matrix is a complex and very time-consuming multi-stage process. This is especially true in the case of casting parts of complex configuration, with recesses, depressions and internal cavities.

For example, when casting a cast-iron or copper vase with a variable surface curvature, you have to use a lot of tricks. Yes, firstthe lower half of the flask is stuffed, then the model is removed, turned over and the upper half is rammed. The model has to be made composite, the handles of the vase are made of two elements, they are pulled out through the model cavity in two stages - first the lower element, then the upper one. All these numerous turnings and dragging cannot have a positive effect on the integrity of the mold surface and, ultimately, on the accuracy of maintaining the dimensions of the casting and the quality of its surface. In addition, there remains the problem of accurately matching the parts of the flasks and securely attaching them to each other.

Production of investment casting is devoid of these shortcomings, it does not require such highly qualified modelers and significantly reduces the labor intensity of pre-casting operations. This is especially pronounced with large runs of castings.

The method allows to reach the 2-5th accuracy class according to GOST 26645-85. This makes it possible to cast high-precision products such as turbine blades, cutting tools, including high-performance milling cutters and drills, critical high-loaded brackets, small high-loaded parts of vehicles, machine tools and other complex mechanisms.

High dimensional accuracy and high surface class minimize the need for further machining of the casting, which saves metal and reduces production costs.

Equipment

The investment casting equipment required is varied and complex. Enterprises unite them into a single and well-coordinated complex,organized as a site, workshop or separate production.

The composition of the complex depends on the scale of production, size, configuration and circulation of castings.

Thus, in the production of dentures and jewelry, the equipment will include:

- model table;

- muffle furnace with thermostat;

- a set of scalpels and spatulas for correcting the shape of the model;

- forming board;

- flask;

- tanks for storing and preparing molding sand;

- set of sand rammer tools;

- crucible for melting metal;

- forceps;

- hammer to break the mold.

This production complex can easily fit on one table and in one cabinet. If it is planned to mass-produce, for example, aluminum castings - parts of a device, then equipment will be required for:

- shaping and pouring ceramic molds;

- drying forms;

- melting out the model material and applying a heat-resistant layer;

- cleaning castings from molding material.

And finally, the actual equipment of the foundry complex, designed to obtain a melt and pour it into a mold. It can be casting equipment:

- under low pressure;

- centrifugal;

- in the usual gravity way.

Injection and centrifugal casting machines are a separate highly mechanized and automatedproduction complex, isolated from the atmosphere of the shop. They minimize manual labor and human exposure to harmful conditions. Sealed chambers in which the complexes are located provide complete capture and purification of exhaust gases, which significantly increases the environmental friendliness of the enterprise.

Lost-wax casting has a fairly high potential for development, especially when combined with advanced mold making and pouring techniques.

Recommended:

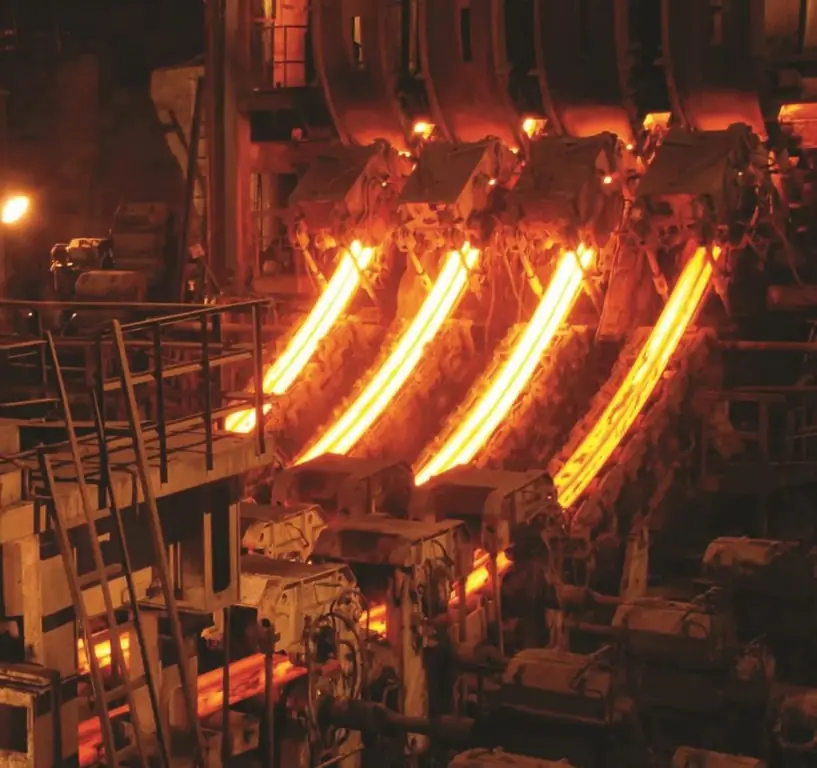

Continuous casting of steel: principle of operation, necessary equipment, advantages and disadvantages of the method

Today, a huge number of various things, parts, etc. are made of steel. Naturally, this requires a large amount of source material. Therefore, the plants have long been using the method of continuous casting of steel, characterized by the most important feature - high productivity

Plexiglas engraving: advantages and disadvantages, technology, equipment

Plexiglas engraving is considered a painting craft. A souvenir figurine, stained-glass windows or a glass table, which are decorated with exquisite drawings, embody a delicate artistic taste. Pickling and sandblasting technologies are in the past. Today, with the help of a laser machine, each person can create a highly detailed pattern

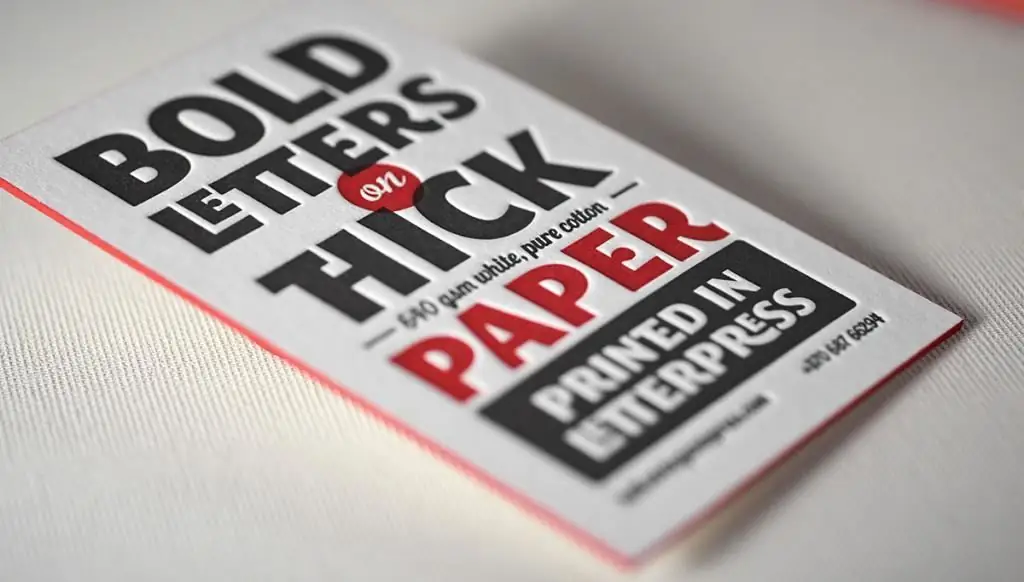

Letterpress is Letterpress printing technology, modern stages of development, necessary equipment, advantages and disadvantages of this type of printing

Letterpress is one of the typical methods of applying information using a relief matrix. The elements that protrude are covered with paint in the form of a paste, and then pressed against the paper. Thus, various mass periodicals, reference books, books and newspapers are replicated

Ultrasonic processing: technology, advantages and disadvantages

The metalworking industry at this stage of development is capable of solving the complex tasks of cutting and drilling workpieces of varying degrees of hardness. This became possible due to the development of fundamentally new ways of influencing the material, including a wide group of electromechanical methods. One of the most effective technologies of this type is ultrasonic treatment (UZO), based on the principles of electroacoustic radiation

Casting in silicone mold: equipment. Vacuum casting in silicone molds

For the manufacture of a small number of plastic blanks, vacuum casting into silicone molds is most often used. This method is quite economical (making a metal mold requires more time and money). In addition, silicone molds are used repeatedly, and this also significantly reduces the cost of production