2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

Chemical plating is a process called chromium plating. It is based on the reaction of the silver mirror. This effect allows you to achieve a shiny finish on the surface of the product.

Chrome Basics

Modern technology of chemical metallization makes it possible to use special paints and varnishes and reagents for the development of spraying. As a result of this, the coating will shine and reflect the surrounding objects. In addition, it is chemical metallization that allows achieving the highest degree of adhesion. It is important that the coating process is carried out without the help of any caustic substances or explosive components. The carcinogenic components of chromium plating are reduced to an absolute minimum. Chemical metallization has no restrictions on the shape and size of the product. There is also no need to place the object in a liquid acidic environment or use high heat.

Surface preparation for chrome plating is similar to the process before applying paint. Thanks to this, mirror coatings can cover any bases, but it is better that they be metallic. Such chemical treatment does not require significant cash injections. It is enough to purchase a special installation and reagents. As a result, the owner of the equipment will be able to apply the "silver mirror" even on porous or organic materials. No other technology can give similar results. Today, chromium plating is a powerful competitor to other metallization processes.

Main stages of technology

The first step in chemical plating is to apply a bonding primer to the surface. A standard paint sprayer will work for this. First, 2-3 layers of binder primer are applied to the surface. It is desirable that this be exactly CH.305. In the case of a porous product, there may be a little more layers.

After obtaining a vitreous coating with a gloss effect, it is necessary to allow the product to dry. As a result, the bonding primer will provide the object with good adhesion, high pollination speed and ideal mirror shine. For the second stage of the technology, the Meta-chromium installation will be required, thanks to which chemical metallization will be carried out. To begin with, the surface is activated by spraying the ST.2516 reagent onto it. After that, the product must be thoroughly rinsed with distilled water. The Meta-Chrome Modifier and AB Series 101 and 202 Reducing Agents are then sprayed onto the surface to form a white, mirror-like metallic coating.

At the final stage, you need to protect the result of chrome plating. For thisa special installation is used to spray the varnish. For optimum protection against wear and tarnishing, it is best to apply multiple coats. Coloring pigments can be added to the protective varnish mixture to give the surface the desired shade. This is how the effect of chrome, gold, bronze, copper and other metals is achieved.

Advantages of Technology

Chemical metallization is a very simple process. Coating is technologically easy. To do this, it is enough to have standard sprayers. This allows coating anything from a phone case to a car hood to a statue. Any materials can be chrome-plated: plastic, ceramics, wood, gypsum, etc. The degree of reflection of the coating depends on the number of applied layers.

Chemical plating gives the product additional strength and hardness. Moreover, the coating has a high wear resistance. The protective varnish is responsible for the strength here, which is able to withstand any operational wear. For the chrome plating process, dimensions do not matter. Any surface area can be sprayed in a short time. This is one of the main differences from the vacuum plating process or electroplating.

Chemical coating is much cheaper than other methods. The average savings is up to 30%. In addition, the coating is environmentally friendly. In the same electroplating process, plating occurs using toxic hexavalentcomponents. When chrome plating, you can choose any color of the coating. To do this, just add a little toner to the composition of the protective varnish.

DIY chemical metallization

Chrome plating can be done by yourself. To do this, you will need a small non-residential premises, protected from moisture and dust, and a special installation that carries out the process of chemical metallization. At the first stage, you should prepare the workplace and clean the product from dirt, rust, paint. Applying a binder primer to the surface is best done with a conventional spray gun. This will allow you to get a perfectly smooth glassy coating. You can dry the product in the sun or under a lamp, the main thing is that it does not get dirty.

The metallization process is considered the most difficult. To do this, you need an installation that will spray special chemicals on the product. As a result of the reaction with the binding primer, a snow-white mirror coating will be achieved. To protect against tarnishing and wear, a special varnish should be sprayed onto the surface. A standard spray gun is also suitable for this. On average, the entire process of chemical chromium plating at home takes about 17-18 hours.

Hardware Requirements

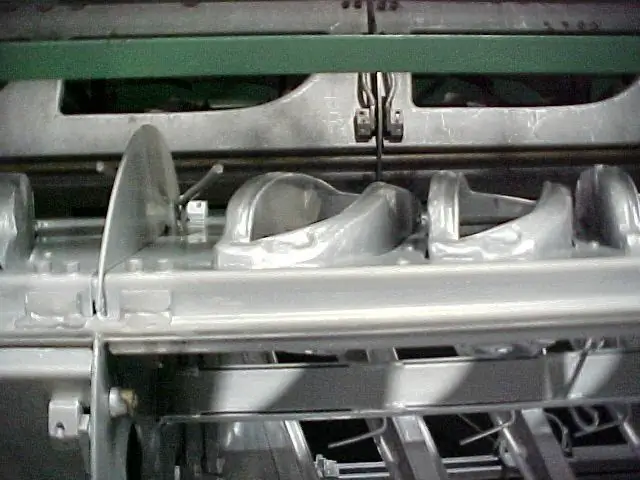

A chromium plating machine must first of all meet the main principles of performance. Equipment for chemical metallization must have at least two pressure tanks with reagents. Their total volume is from 12 liters. This will significantly extend the timeprocess.

For beginners, an important aspect is information content, so all buttons must be signed on the installation. It is important that all pressure gauges on the front panel are in close proximity to the pressure regulators. Equipment for chemical plating must be ergonomic. The presence of filler necks in the unit allows you to dynamically add reagents to the tanks as needed. The main requirement for the manifold is a check valve. Thanks to him, the reagents will not mix.

High reliability of the equipment is achieved by high quality control. Therefore, the installation must necessarily belong to one of the world's leading brands. If the warranty period is less than three years, then you should not waste your money. Since the process of chemical chromium plating is harmless, the equipment itself must be environmentally friendly. It is important that reagents do not leak from the tanks. Expensive units have automatic air filtration. In such atomizers, the compressor cleans the microparticles from grease and oil.

Special equipment

The most common chemical plating machine is the Meta-Chrome/Pro-1. Its distinguishing features are built-in temperature indication in subsystems, one-stage air filtration, a manifold with a backdraft valve, a tank depressurization design, an enlarged air hose for applying pressure to the gun. This is a very compact device, in the packagewhich includes an airbrush, a set of reagents for 20 sq. m, a box for reagents, toners and a telemetric conductivity meter. The cost of such an installation is about 120 thousand rubles.

Meta-chrome/Pro-2 is an improved version of Pro-1. Of the additional functions, it has an indication of the conductivity of the liquid in the tank, a two-stage filter and built-in drain taps. The kit includes 2 spray guns, reagents for 60 square meters. m, a container for reagents, 6 toners and a conductivity meter. The cost of this installation is about 140 thousand rubles.

Main reagents

All reagents for chemical plating must be prepared with specially filtered water. Due to this, high light resistance and a minimum coating thickness (up to 0.4 microns) are achieved. It is important that the solution contains the maximum concentration of the reagent. Reagents for chemical plating should not contain carcinogens and substances that irritate the respiratory tract. Set for 20 square meters. m should contain reagents in the following volume: bonding primer - 3.3 l, protective varnish - 1.6 l, modifier - 1 l, activator - 1 l, reducing agent - 1 l, hardener - 0.5 l, pigment toners - 40 ml. The cost of such a set will be about 20 thousand rubles.

Additional reagents

It is not uncommon for large production to run out of individual reagents for chemical plating. Therefore, it is important to take care of buying a spare set of necessary substances in advance. However, there is a cheaper option - retail purchasereagents.

At the moment, reagents for chemical metallization can be found on the free market at the following approximate prices (ratio per 1 liter of liquid): bonding primer - 1500 rubles, protective varnish - 1450 rubles, reducing agent - 1350 rubles, stabilizer - 1200 rubles, activator - 900 rubles, hardener - 700 rubles. The modifier is considered the most expensive - 7300 rubles. per litre.

Test data

Multiple studies have shown that a coating applied by chemical plating can withstand an impact of 55kg/cm2 without leaving any marks. In addition, chrome particles do not remain on the adhesive tape. The coating has also successfully passed the s alt spray test. Thus, it is completely protected from corrosion and clouding.

Recommended:

MPC of hydrocarbons: chemical factors of the working environment

MPC of hydrocarbons in the air of the working area at enterprises and in the environment, of course, must be observed without fail. Harm to the human body, compounds of this variety, unfortunately, can cause significant

Bronze is an alloy composition. The chemical composition of bronze

Many people know about bronze only that sculptures and monuments are cast from it. In fact, this metal is undeservedly deprived of popular attention. After all, it was not in vain that in the history of mankind there was even a Bronze Age - a whole era during which the alloy occupied a dominant position. The qualities possessed by an alloy of copper and tin are simply indispensable in many industries. It is used in the manufacture of tools, in mechanical engineering, casting church bells, and so on

Graphite grease: all the secrets of the chemical

Among the huge variety of all kinds of lubricants, graphite grease is not the last. Its application has a strictly defined area, which is due to its properties

What are chemical reactors? Types of chemical reactors

Chemical reactors are containers designed to carry out reactions in order to produce the final product. Their design depends on various factors and should provide maximum output in the most cost effective way

Vacuum metallization - technology description, device and reviews

The article is devoted to vacuum metallization. The features of the technology, the device of the equipment used, reviews, etc. are considered