2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

Okuchnik - a device for tillage. It is used in the household and on an industrial scale. For personal use, you can make disk hillers with your own hands.

Disk hiller: what is it?

Inventory design is simple. It looks like a metal frame to which wheels are attached and disks are suspended. Let's try to make a disk hiller with our own hands. We will also draw up design drawings ourselves. To assemble the equipment you will need the following:

- lanyards (screw) - help to adjust the angle of rotation of the disks;

- T-Leash;

- discs of a certain diameter;

- racks (2 pcs.).

Adjustable racks change the distance between the edges of the discs. The minimum width is 35 cm, the maximum width is 70 cm.

Disks must have the same rotation angles. You can do this with lanyards. The inclination of the discs is not adjustable. This indicator does not change after the assembly of the structure.

If the inventory will be used for a walk-behind tractor, it is necessary to provide for the diameter of the wheels of the equipment. It should is 70 cm wide- 10-15 cm. In this way, the wheels will not be able to damage the row spacing and planted crops.

Also inventory can be used manually. The main structural elements are similar to those described above. At the same time, the holder for the hiller is a metal pipe with a diameter of 2-5 cm. This parameter directly depends on the size of the future structure. All elements of equipment are welded to it.

Make inventory yourself

To build a disk hiller with your own hands, almost no financial investments are required. It can be made from improvised means.

Surely every person in the pantry has old pots that he does not use. We need covers from them. They should have a diameter of 40-60 cm. They must be sharpened along the edges, for example, using a lathe.

Then the lids need to be bent in such a way that there is a convex plane on one side and a concave one on the other. This is necessary so that when you make a disk hiller with your own hands, it would raise the ground and sprinkle the bushes. In addition to pots, you can also use old disks from a seeder.

In addition, you will need:

- T-Leash;

- lanyards (2 pcs.);

- racks (2 pcs.).

All structural elements are bolted together. To increase strength, they can be welded to each other. The discs are connected by adjustable conductors. They are installed symmetrically on both sides. The distance between them should correspond to the widthspacing.

The resulting structure is attached to the walk-behind tractor bracket by means of a leash, bolts and washers. It is necessary to check the quality of the connections so that after you make the disk hillers with your own hands, they do not deform during operation.

How the equipment works

The described inventory is designed for hilling potatoes and other vegetable crops. And despite the fact that it can be purchased in specialized stores, it is more economical to make disk hillers with your own hands. It is attached to the walk-behind tractor with bolts, washers and a stopper. During the operation of the walk-behind tractor, the disks begin to rotate. At this time, they capture part of the soil and create a roller. The rotation of the disks allows you to crush the earth and loosen it.

Everyone can make a manual disk hiller with their own hands. It helps to quickly and efficiently cultivate the soil before sowing and after harvesting. Also, with its help, row-spacings are processed and potatoes are spudded. As we have said, this device is installed on a cultivator or walk-behind tractor.

Disk Hiller Options

This equipment is widely used in agriculture. With its help, the ridges are smooth and high. Accordingly, the time spent on processing row spacings is reduced, and working with the device is quite simple.

There are certain parameters that the manufactured disk hillers must meet. You also need to do them with your own hands, remembering the following:

- about thicknessdiscs;

- their diameter;

- material for manufacturing;

- equipment adjustment mechanism.

Based on the drawing proposed in the article, you can make inventory yourself and save a lot of money.

Inventory specifications

Advantages of this equipment:

- ease of operation - the device is mounted on a walk-behind tractor or a metal handbrake;

- strength - the structure is securely fastened with bolts and washers;

- durability - the life of the equipment is more than 10 years (with proper care);

- versatility - inventory can be used for hilling any vegetable crops.

In the garden you can not do without such a device. It can be purchased ready-made or made independently. Hillers, which are sold in specialized stores, are endowed with excellent technical characteristics. They have one drawback - high cost. Homemade products can be built from improvised materials. This will save you a lot of money.

Recommended:

Quail food: composition, norm, recipe and price. How to make quail food with your own hands?

Own home garden for many has become a symbol of their own vegetables and fruits, which allow you to diversify your table with fresh and environmentally friendly products. Some breed chickens, geese and ducks in order to provide themselves with meat

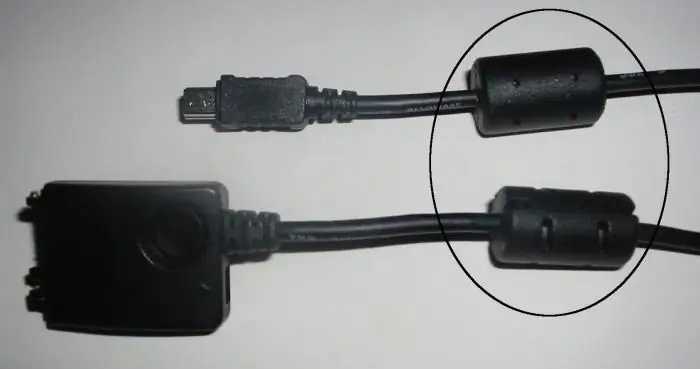

Ferrite ring - what is it? How to make a ferrite ring with your own hands?

Each of us has seen small cylinders on power cords or on cables for matching electronic devices. They can be found on the most common computer systems in the office and at home, at the ends of the wires that connect the system unit to the keyboard, mouse, monitor, printer, scanner, etc. This element is called the "ferrite ring". In this article, we will look at the purpose for which manufacturers of computer and high-frequency equipment equip their cable products with these elements

How to make a substrate for oyster mushrooms with your own hands at home

Growing mushrooms at home allows you to harvest all year round and earn extra income. You can grow these plants in any room where you can create an optimal microclimate. To get a good harvest, it is necessary to prepare the mycelium and substrate for oyster mushrooms and other types of mushrooms

We create automatic watering with our own hands

Anything that grows on your site and deserves to grow there needs regular watering. But often we are controlled by circumstances that we cannot overcome

Disk sawmill with their own hands. Disc mini-sawmill

The woodworking industry cannot do without a high-performance sawmill. This tool has not only high speed and productivity, but also the desired quality. But despite the fact that this is the most successful solution that exists today for processing a large number of workpieces, not everyone can buy such a tool. A circular sawmill can be made with your own hands. This will take time, desire and tools