2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

Open Joint Stock Company "Guryev Metallurgical Plant" is the oldest enterprise in Kuzbass. The GMZ has become a locomotive for the development of industry in the Kemerovo region and South Siberia as a whole. Today, the company produces rolled products, channels, angles, profiles, balls for various purposes.

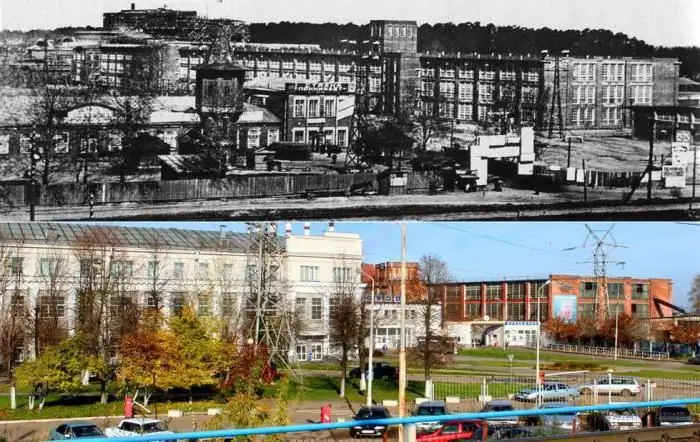

Historical value

The most industrially developed region of Siberia is the Kemerovo region. Southern Siberia has traditionally been known in Moscow as a local center for ironworks. The formation of the metallurgical industry of the region is associated with enterprises built in the 18th-19th centuries, one of which is the Guryev Metallurgical Plant.

GMZ is a city-forming enterprise. Initially, silver was smelted here, but in 1844 it was transformed into a center of ferrous metallurgy and continues to operate to this day. Production became the basis for the metallurgical giant of the 20th century - KuznetskMetallurgical Combine (KMK).

Creation

Guryev Metallurgical Plant (GMZ) was built in one season and launched in 1816 as a silver and copper smelter for processing Salair ore. For a month and a half of work, about 50,000 poods of ore were smelted in four furnaces of the plant, from which more than 10 poods of enriched silver concentrate were obtained. In 1817, six more smelting furnaces were put into operation, and in 1818, more than 1 million poods of ore were smelted at the plant, from which 200 poods of silver were smelted.

Repurposing

With the development of the region's economy, the emergence of gold mining in the Salair Territory and the development of coal deposits, the chief designer of the plant P. M. In 1826, the first blast furnace was launched, and soon an ironworks was built at the plant. Since that time, the Guryev Metallurgical Plant has been changing its profile.

Slowly, iron production becomes the main one. At the beginning of 1840, the iron-smelting department finally replaced the silver-smelting department, and in 1844 the enterprise began to function as a ferrous metallurgy plant. Products of Guryev metallurgists from damask steel were presented at the international exhibition of 1851, held in London, where they were awarded silver medals.medals.

Locomotive of the economy

Guryev Metallurgical Plant stood at the origins of metallurgy and engineering in Western Siberia. In 1860, a mechanical factory started operating within the walls of the enterprise (which became the first beyond the Urals). It included five workshops: assembly, forging, boiler equipment, foundry, model. The newly formed factory specialized in the assembly of steam engines, tools and tools for mining. The Guryev plant was the only ferrous metallurgy production east of the Ob. He supplied products for agriculture and industry throughout the region.

Guryev Metallurgical Plant: bankruptcy

After the laying of the Siberian railway at the end of the 19th century, it became difficult for the products of the Guryev plant to compete with the metal supplied from the Urals and foreign manufacturers. It was necessary to carry out the reconstruction of capacities, but the authorities chose to stop production.

The plant stopped iron smelting in 1907, and iron smelting in 1908. The company was mothballed and declared bankrupt. The Guryev plant in the spring of 1913 was transferred to the joint-stock company Kuzbass coal mines, which used the capacities as auxiliary ones. Mining boilers, pumps, steam engines were repaired on the territory, trolleys, winches for mines, steam engines, tools were made. In 1914, in the workshops of the Guryev plant, equipment was manufactured for the coke oven battery under construction in Kemerovo andchemical plant.

Beginning of the Soviet era

After the revolution in the 20s, a radical reconstruction of the enterprise was carried out. In 1922, a blast furnace was put into operation, and the first cast iron smelted on coal was obtained. Since 1924, open-hearth steel has been smelted, a year later the plant began to produce rolled products. Thus, the GMZ became the first production facility beyond the Urals with a full metallurgical cycle.

In 1929, he produced 6221 tons of pig iron, 8629 tons of iron and steel blanks, 7940 tons of rolled products, 7464 tons of cast iron, 3188 tons of refractories. The enterprise produced valuable and irreplaceable products for new industrial construction, operating enterprises throughout Siberia. First of all, these are rails, long products, angle and reinforcing iron, casting, bolts, etc. During the period from 1925 to 1940, the production of the main types of products at the Guryev Metallurgical Plant increased significantly: steel from 1168 to 35045 tons, rolled products from 1299 to 48643 t, refractories from 3000 to 10156 t, castings from 784 to 6605 t.

Role in the development of metallurgy in Kuzbass

One of the most important merits of the GMZ is participation in the construction and initial development of the giant of metallurgy - the Kuznetsk Iron and Steel Works. The Guryev Metallurgical Plant, whose activity from March 1929 to 1932 was completely devoted to Kuznetskstroy, was a support base for construction and initial development. The veteran of the Siberian metallurgy provided the Kuznetsk plant with the necessary qualified personnel, parts, and materials. Equipment designed for KMK was tested in its workshops.

The Great Patriotic War and post-war development

Metallurgists of the GMZ during the war mastered the rolling of shaped profiles. The enterprise was the only supplier in the USSR of thin-walled complex rolled profiles for the aircraft industry. After the end of the Second World War, the plant produced alloyed and open-hearth steel, rolled products, spare parts for agricultural machines, building bricks, various metal products, structures and equipment, which were so necessary for the restoration of the economy.

Production in the 60s became unprofitable due to unequal competition with KMK. In 1970, a large-scale process of reconstruction of technological capacities began. Thanks to the mechanization of the most labor-intensive operations, the administration managed to restore profitability and regain the trust of customers.

New time

Since September 1993 GMZ has been a joint stock company. Having become the first-born of the Siberian industry, OJSC "Guryev Metallurgical Plant" lost its former importance on the scale of Kuzbass. However, for the residents of Guryevsk, the plant remains a city-forming enterprise, it employs 1,500 people. This is the fourth part of the townspeople employed in big business. The share of GMZ payments in tax revenues is more than 30% annually. In 2003, a new management company, CJSC ITF Group Holding, came to the enterprise.

In the last decade, competition in the metallurgical market has increased many times over. In 2008-2009 major equipment upgrades were carried outmodernized production. In particular, the capacity of open-hearth furnace No. 1 was increased, thanks to which the productivity reached 110,000 tons of steel annually.

For modernization, borrowed money from creditors was attracted. However, the debt has yet to be paid off. Despite stable operation, the plant has been on the verge of bankruptcy since 2013. In 2014, external management was introduced, and in 2016 the GMZ was declared insolvent. However, both creditors and employees of the enterprise are in favor of continuing the work of production that is important for the region.

Products

Today, Guryev Metallurgical Plant OJSC (TIN 4204000253) produces the following types of metallurgical products:

- Steel balls of various types.

- Steel round bars.

- Round bars designed for drum mills.

- Square steel bars.

- Equal-shelf angle steel.

- Steel channel.

- Asymmetrical strip bulb for shipbuilding.

- Special lightweight profile for conveyors.

- Special braid profile.

- Profile for wagons.

GMZ (Guryev Metallurgical Plant): reviews

GMZ is the main enterprise of the city of Guryev and the largest taxpayer in the region. Work in production is considered prestigious due to the good (for the region) salary. Although financial problems dominate the plant, the team stands for the preservation of the native enterprise. Thanks tomodernization carried out in recent years, working conditions have improved significantly.

Positive feedback is heard from the customers of the Guryev plant. Partners note the efficiency of order fulfillment, decent quality and attractive prices for products. Dissatisfaction is expressed by creditors who expected to increase their investments. Meanwhile, they are in favor of continuing the operation of the enterprise.

Recommended:

Vyksa Metallurgical Plant: contacts. Pipes of the Vyksa Metallurgical Plant

OJSC VMZ (Vyksa Metallurgical Plant) is a leader in the production of wheels for railway transport and rolled pipes. This is one of the oldest Russian industrial enterprises. Part of JSC OMK-Holding

JSC "Ashinsky Metallurgical Plant": history, production, products

JSC "Ashinsky Metallurgical Plant" is a city-forming enterprise in the west of the Chelyabinsk region. AMZ is one of the top five Russian suppliers of thick plates, nanocrystalline and amorphous alloys. Leader in the production of tableware, household items and garden tools from stainless steel

JSC "Yaroslavl Tire Plant": description, products, production and reviews

JSC Yaroslavl Tire Plant without exaggeration is the leader of the country's tire industry. Every year, the company produces about 3 million units of high quality products for various types of equipment. The company is part of the holding "Cordiant"

REMIT Meat Processing Plant LLC: feedback from customers and employees, manufactured products and quality of meat products

REMIT reviews are of interest to customers who are considering options for cooperation with this company, and employees who expect to get a well-paid and stable job. In this article, we will talk about this meat processing plant, what products it produces, whether its quality corresponds to the declared one, what its employees and partners say about the enterprise

PJSC "Nadezhda Metallurgical Plant" (metallurgical plant named after A. K. Serov): address. Ferrous metallurgy

PJSC "Nadezhda Metallurgical Plant" is among the top ten domestic producers of rolled steel. In addition to steel, the company produces cast iron, manufactures concrete and reinforced concrete structures. NMZ is located in the north of the Sverdlovsk region, in the city of Serov