2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:33

JSC Yaroslavl Tire Plant without exaggeration is the leader of the country's tire industry. Every year, the company produces about 3 million units of high quality products for various types of equipment. The company is part of the Cordiant holding structure.

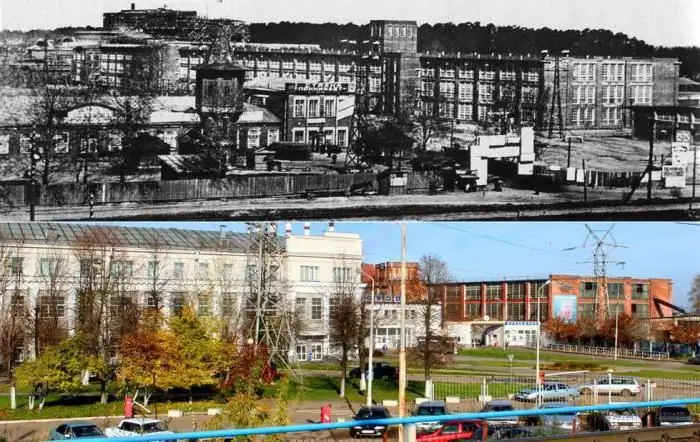

Prerequisites for creation

By the end of the 1920s, the Soviet Union had overcome the stagnation and devastation caused by the revolution and the Civil War. The new economic policy and the course towards industrialization contributed to a qualitatively new development of the country's industry. One of the most important areas was the increase in the production of mechanized vehicles: cars, trucks, buses, military equipment.

However, mass production of vehicles is impossible without such a seemingly simple thing as tires. Cameras and tires were not produced in the USSR, and it was too expensive to buy from foreign companies for foreign currency. In 1928, the government made a fundamental decision to establish its own tire production. And since domestic technologies andthere was no equipment, it was decided to involve partners from the USA in the construction of a new enterprise.

The first in the USSR

The city of Yaroslavl was chosen as a site for the construction of a rubber-asbestos plant. The development of the Yaroslavl Tire Plant, the subsequent installation of equipment and commissioning was carried out by the American company Seiberling. According to the plans, the enterprise was destined to become the first in the Soviet Union, and the fourth largest in the world.

The first batch of tires was received on 1932-06-11. In 1933, the tires of the Yaroslavl tire plant began to be made from a revolutionary new material developed by Soviet scientists - synthetic rubber. It was obtained from petroleum, which is much cheaper than natural rubber. For labor achievements and the introduction of innovative technologies, the plant's staff was awarded the Order of Lenin.

War

During World War II, the significance of the Yaroslavl tire plant increased many times over. In fact, it was the only enterprise where large-scale production of tire products was carried out. YaShZ produced tubes and tires for vehicles, aircraft, artillery, and armored vehicles.

In order to disrupt the work of a strategically important enterprise, Wehrmacht aviation on June 10 launched a massive airstrike on industrial facilities, turning the plant into ruins. However, in a matter of months, the townspeople restored the main production, and by the end of the war, his work was continued.

Postwardevelopment

In 1946, a large-scale reconstruction began at the Yaroslavl Tire Plant. The main goal was to mechanize technical processes as much as possible in order to increase productivity and facilitate the work of workers. After the introduction of direct flow technology, the company began to manufacture new types of products: belts, bracelets, protectors.

The factory workers were the first in the USSR to replace the manual docking of cameras with a mechanical one, for which they developed special docking machines. A little later, units were introduced for crimping the edges of bracelets and pulling bracelets onto a drum. These and other inventions began to be applied at other profile enterprises of the country.

On the edge of progress

50s were marked by innovations. Again, YaShZ was the first in the Union to master the production of tubeless tires. They were intended for representative passenger cars Volga, ZIM, Pobeda. A breakthrough was the development of the production of large tires with increased strength for giant dump trucks, in particular, the 25-ton MAZ-525. Unique arched tubeless tires designed by P. A. Sharkevich were made for ZIL-150 off-road trucks.

In the early 50s, the Minsk Tractor Plant launched the Belarus tractor, which became the most massive in the vastness of the USSR. The administration of the Yaroslavl Tire Plant was instructed to supply tubes and tires to such a large-scale production. The team provided the necessary volume of production. In addition, YaShZ agricultural tires were the first in the country to be awarded the highest quality category.

Workdays

By this time, the number of vehicles and military equipment produced in the Soviet Union had increased significantly. However, there were not many tire manufacturers. The so-called "tire crisis" broke out in the country. Rubber products became a real shortage, a lot of equipment was idle.

Under these conditions, the company has set a goal to increase productivity. However, it was impossible to achieve fundamental changes with the old methods. The plant decided to take a different path - to improve product quality (to reduce wear), introduce new tire designs and automate technological operations as much as possible. The designers have created new tires of the "RS" series (with removable treads) and "P" (radially located cord threads).

Since 1969 Yaroslavl Tire has been manufacturing products for VAZ. Two years later, the work of the factory workers was awarded the Order of the October Revolution. In 1981, the company produced the 200 millionth tire.

From plan to market

Unlike many giants of chemistry of the Soviet times, YaShZ survived the competition and today is a model of a successful high-tech enterprise. The company produces popular products under the Cordiant brand. Thanks to an extensive network of dealers, the Yaroslavl Tire Plant is widely represented in the domestic and foreign markets.

In 2013, the management decided to abandon some activities and focus on the manufacture of tires for cars. ATin connection with which the production of aircraft tires was moved to Barnaul.

Products

Yaroslavl Tire Plant today produces over 70 models and sizes of tires in four areas:

- for SUVs;

- cars;

- light trucks;

- trucks.

The following series of Cordiant tires are produced for cars and crossovers:

- Snow Cross.

- Winter Drive.

- Polar.

- Sport.

- Sno-Max.

- Road Runner.

- Off-Road.

- All-Terrain.

Tire series for trucks:

- Business.

- Professional.

Reviews

Yaroslavl tire plant, according to consumers, produces sufficiently high-quality products that can compete with foreign brands. Modern technologies used in production allow us to keep up with the world market leaders. We must not forget that Yaroslavl tires are optimized for Russian roads. They retain performance in various climatic zones, whether it be the Kuban or Siberia. Of course, an important component is the affordable price of products and a wide range of models.

Among the advantages of products, drivers note wear resistance, good grip on wet pavement, lack of hydroplaning, cornering stability, low noise, affordable cost. Among the shortcomings is a noticeable deterioration in grip when the tires wear out. Overall brand loy altyhigh.

Recommended:

JSC "Arzamas Instrument-Making Plant named after P. I. Plandin": overview, products and reviews

OJSC "Arzamas Instrument-Making Plant named after Plandin" is a city-forming enterprise, on the work of which the well-being of the one hundred thousandth city of Arzamas depends. It produces hardware components and devices for the aviation industry, the space industry, and civil applications

JSC "Guryev Metallurgical Plant" - overview, products and reviews

Open Joint Stock Company "Guryev Metallurgical Plant" is the oldest enterprise in Kuzbass. The GMZ has become a locomotive for the development of industry in the Kemerovo region and southern Siberia as a whole. Today the enterprise produces rolled products, channels, angles, profiles, balls for various purposes

Tire service business plan: sample, example. How to open a tire shop from scratch

Tyre service can bring a good income. Before investing in your own business, you should draw up a competent business plan

JSC "Bor glass plant" (BSZ): description, products and production features

JSC "Bor glass plant" is the leading manufacturer of auto glass in Russia. Since 1997 it has been owned by the AGC Europe group of companies. The company also produces: dishes, mirrors, polished glass and other products

REMIT Meat Processing Plant LLC: feedback from customers and employees, manufactured products and quality of meat products

REMIT reviews are of interest to customers who are considering options for cooperation with this company, and employees who expect to get a well-paid and stable job. In this article, we will talk about this meat processing plant, what products it produces, whether its quality corresponds to the declared one, what its employees and partners say about the enterprise