2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Before sowing various kinds of crops, soil cultivation is mandatory. Grains, vegetables, flowers, etc. can actively grow and develop only on loose, well-fertilized soil free from weed roots. The first, deepest tillage after the previous crop is called the main one. Most often, this procedure is performed in the fall.

Basic tillage practices

Prepare the soil in the fields before sowing any crops, in most cases, of course, by plowing. Also, sometimes peeling can be done to loosen the soil. In any case, the purpose of the main tillage is to improve its air and moisture permeability. After loosening, the roots of plants planted in the field easily get all the nutrients they need from the ground.

Plowing the soil, in turn, happens:

- with full reservoir rotation;

- with uplift;

- cultural;

- non-moldboard;

- flat cut.

Peeling technology is often used in the fields in combination with non-moldboard plowing.

Special moves include:

- milling;

- tiered;

- multilayered.

The main methods of tillage for planting allow you to prepare the highest quality. However, in order to improve the properties of the land, such procedures as harrowing, rolling, cultivation, loosening can also be carried out on farms. All these methods are already related to additional tillage.

How plowing is done

This procedure is performed, as already mentioned, in the fields, usually in the fall after harvest. The set of measures aimed at improving the structure of the soil is thus called the autumn main tillage system. After plowing, in this case, the land goes into winter, or “chills”.

Produce deep loosening in the fields of large agricultural enterprises with tractors. At the same time, the actual main and pre-sowing tillage is carried out by means of special attachments - plows. Tractors for plowing, milling, peeling are usually used on wheels. But in difficult areas, such a procedure can also be carried out on caterpillar tracks.

In small farms, the main tillage can be carried out on mini-tractors, motoblocks, motor cultivators. This technique is easy to operate and can greatly facilitate the life of the farmer.

Varieties of plows byfastening method

This procedure in the fields is carried out using plows, which can be:

- mounted;

- semi-mounted;

- trailed.

The first type of tools is attached to the tractor from behind using a linkage mechanism. For the main tillage on the machine, such a plow is installed in an elevated position. When plowing, this equipment goes down, and its working part is buried in the ground.

Semi-mounted plows additionally have a rear support wheel. It is necessary for raising and lowering the tool and adjusting the depth of plowing.

Trailed plow consists of a frame based on three wheels, a trailer, working bodies and control mechanisms. Such equipment is used where it is impossible to carry out high-quality tillage with mounted or semi-mounted soil.

Types of plows by design

By the nature of the work performed, the implements of the main tillage can be special or general purpose. The first type includes, for example, forest plows, swamp plows, etc. By the type of working body, such equipment can be share or disk. Also, when plowing the land, single and multi-body plows are used.

Share plow design

This type of general purpose equipment is used to cultivate old arable land. To prepare soddy soil, plows with semi-screw bodies are used. The design of such attachments includes:

- stand;

- dump - a vertical part designed to dump seams;

- ploughshare - the lower part that cuts the soil in front of the blade.

Eroded lands in arid regions are plowed without mouldboards. Hard soils and loams can be processed using this type of retractable chisel equipment. There are also plow models equipped with a deepening share.

When plowing, among other things, skimmers are very often used. They are a small copy of the plow and are installed in front of it. With their use, the main tillage can be done better.

Full rotation plowing with uplift

Methods of seedbed tillage in farms can be used different. For example, plowing with a full turnover of the formation is used on virgin lands or heavily sodded areas. In this case, work is often carried out with screw or semi-screw plows. The turfed part of the formation, when plowing in this way, turns over 180 degrees. Then it lies on the bottom of the furrow.

Reception of the main tillage with uplift of the layer is used when plowing fallow, plowing or incorporating manure. A feature of this procedure is that it is performed without a skimmer by general-purpose plows.

Cultural plowing

The main tillage according to this technology is carried out on old arable lands. It is this technique that is used in farms most often and most fully satisfiesthe requirements of agricultural technology. Cultural plowing is carried out with general-purpose plows with skimmers. Soil cultivation according to this method looks like this:

- the skimmer cuts a thin layer of soil 2/3 of the width of the main layer and dumps it into the furrow;

- ploughshare of the main plow cuts through the soil to the required depth, and the blade wraps the layer by 130-150 degrees.

As a result, the cut out main layer covers the thin layer of soil laid earlier by the skimmer in the furrow.

What rules should be observed during cultural plowing

To cultivate the soil before sowing should, of course, with strict observance of all the required technologies. Otherwise, a good harvest of agricultural crops will not be possible. According to regulations:

- When plowing, it is necessary to observe the depth prescribed for a particular crop or type of soil. The main tillage is carried out so that on a flat field the deviations are not less than 1 cm, and in difficult areas - 2 cm.

- The cross section of the seams must be the same, and their turnover must be complete.

- Weeds, stubble and applied fertilizers must be incorporated into the soil as efficiently as possible.

- The arable unit must move straight across the field without leaving flaws.

- The surface of arable land should be continuous. The only exception in this regard is the plowing. In this case, the surface is slightly ribbed.

- Dumping ridge heightshould not exceed 70 cm. The depth of the breaking furrow should not be more than ½ of the depth of the plowing itself.

- In fields with difficult terrain, plowing should be done across slopes.

All these agrotechnical requirements for the main tillage make it as loose as possible and suitable for growing crops.

Plowing depth

Loosening the soil during the main processing is carried out, of course, in compliance with certain standards. The depth of plowing depends primarily on the type of land in the field. So:

- on sod-pozolic soils it can be 18-28 cm;

- on chernozems and other soils with a thick arable layer, the plowing depth is usually 28-30 cm.

Deep plowing allows you to make the soil as suitable as possible for growing crops. This technology provides the best aeration of the land and reduces the number of weeds on the field. However, deep plowing requires significant tractive effort. And this, in turn, increases the cost of processing fields. It is customary to carry out deep plowing in farms only when it is known for sure that in this way it is possible to increase the yield of a particular crop. Sometimes this technique can even worsen the quality of the soil. This happens on lands underlain by unfavorable horizons, where the subsoil layer can turn up.

Whatever the main processing technologythe soil was not used, loosening it in different years before planting agricultural plants relies on unequal depth. Otherwise, a plow pan may form under the topsoil. And this, in turn, will lead to stagnation of water in the fields after irrigation and rains, or, conversely, its rapid runoff in areas with a slope.

Multilayer plowing: basic rules

This is the name of layer-by-layer tillage with the movement of soil horizons at different levels. This method is used to create a powerful cultivated layer, most often when planting forest belts. Of course, it can also be used in the cultivation of any crops, such as cotton.

Such plowing can be two- or three-tiered. In the first case, processing is carried out with wrapping the top layer of the earth and simultaneous loosening of the bottom. This allows you to improve the properties of the soil to a considerable depth. Sometimes such plowing is also carried out with the mutual movement of the upper and lower layers. With three-tier plowing, the top layer 10-15 cm thick moves down, the bottom layer (25-40 cm) goes up, and the middle layer (15-25 cm) remains in place.

The main advantage of both of these technologies is good crumbling and deep incorporation of crop residues. When using a multi-tiered technique, the same cotton plant significantly accelerates its development and increases yields.

Soilless tillage: benefits

The main tillage when using this technology is carried out without turning the arable layer at all. This method of plowing is used formostly in the Trans-Urals. This technique was developed by T. S. M altsev, and the loosening itself is carried out in this case using a plow of a special design. The advantage of this plowing method is, first of all, the reduction of crop losses due to diseases and insect damage. Mushroom spores, larvae, etc., remain on the surface of the earth during non-moldboard processing. As a result, they simply die in the winter season.

Also, when using this technology, the soil is very well loosened, and up to 50% of stubble remains on its surface. In addition, non-moldboard plowing has the following advantages:

- allows you to maintain the water balance in the earth;

- protects the soil from weathering.

Unharvested stubble subsequently holds snow on the soil surface. The thickness of the cover on the fields with the lower parts of the grain stalks remaining on them is usually 2-3 meters more than on the plowed fields. As a result, in spring, when snow melts, the soil in such areas is saturated with moisture to the maximum. Also, due to the thick cover, the land in the fields cultivated by this method does not freeze too deep.

Another advantage of having stubble in the field is to prevent the formation and transfer of large amounts of dust in strong winds. This allows you to completely preserve the top nutrient layer of the soil.

Middleless plowing technology

This procedure is carried out on the fields of agricultural enterprises once every 4-5 years. FROMThe soil is loosened to a depth of 35-40 cm with the help of non-moldboard plows. In the period between deep plowing, annual surface peeling is carried out.

This operation in this case can also be considered the main tillage. Surface tillage in this case is carried out by disc ploughshares to a depth of 10-12 cm. Sometimes this procedure is performed twice in the fall:

- immediately after grain harvest;

- at the beginning of autumn, no later than October 5.

Also, when using non-moldboard basic and pre-sowing tillage in early spring and early summer, the fields are harrowed. This technology prevents moisture loss through the crust.

Middleless plowing: a bit of history

This unique method of basic tillage was invented by T. S. M altsev at a time when he was still an ordinary field crop of the Zavety Ilyich collective farm in the Kurgan region. Later, he argued on this topic with Lysenko, who believed that it was necessary to plow as deep as possible, turning the layer well. Each of the researchers considered his method to be the only correct one and gave this a lot of arguments.

But the majority of academicians in those days, of course, still sided with "science" and supported Lysenko. However, no one began to forbid M altsev to set up practical experiments on the non-moldboard technology of the main tillage. And in 1955, when almost all the virgin land burned out during a drought, grain crops were produced in the fields of this researcher, although not too large, but still a crop. As a result, the farmer provedhis correctness, and he was awarded the title of Hero of Socialist Labor. Later, M altsev became a corresponding member of the Agricultural Academy.

In subsequent years, the struggle against his "pseudo-scientific" method still continued. And again, during the drought and strong winds of 1963, his fields, unlike those cultivated in the traditional way, gave a harvest. After that, the majority of academicians recognized M altsev's correctness, and today his method of basic tillage is used quite widely.

Design of disc plow

Such equipment is usually used for plowing the soil. In addition, such plows can be used on difficult soils - virgin soil, on the site of uprooted forests, on stony heavy lands, swamps, etc. Plow equipment in such fields, having met with an obstacle, can simply break. The disc plow will roll over it without any damage to itself.

The main elements of such equipment are:

- spherical discs with a diameter of 0.6-0.8 m;

- front frame with hitch to attach to tractor;

- rear frame;

- two front and two rear disc cases;

- stabilizing knives;

- support wheel with adjustable plowing depth.

Flat cutting technology

It is also one of the basic tillage. This technique is common in areas with strong wind erosion. Very often flat cutting technologyused in Siberia, the Urals, the North Caucasus. In this case, the soil layers also do not turn around. At the same time, most of the crop residues remain on the field. That is, in fact, flat-cut tillage is a kind of non-moldboard.

Loosening when using this technique is carried out by cultivators for the main tillage or flat cutters. In the first case, the soil is processed to a depth of 20-30 cm, in the second - 10-15 cm.

Rules for flat cutting

Using this plowing technique, among other things, the following standards are observed:

- stubble on the field should remain at least 80-85%;

- when loosening with cultivators, deviations from the desired depth should not exceed 5 cm, with flat cutters - 2-3 cm;

- rollers at the junction of passages and paws in height should not exceed 5 cm;

- weed roots along the working body used to process equipment must be cut completely;

- breaks between adjacent passes are not allowed.

Special Techniques: Milling

According to this technology, primary plowing is most often carried out on peat soils after the swamps have been drained. Also, this technique is used on heavily sod meadow soils. Milling provides crumbling and thorough mixing of the processed layer. Such processing, in fact, includes plowing, cultivation and harrowing at the same time.

The soil is loosened using this technology on tractors usingspecial milling machines with mounted or trailed drums. The technique of such plowing looks like this:

- in one pass of the milling machine (with the drum grate raised), the soil is loosened to a depth of 16 cm;

- leave the field for 3-5 weeks to settle and compact the treated layer;

- mill the ground again to a depth of 18-20 cm with the grate lowered so that plant residues and large pieces of sod are covered with a loose layer of soil.

When processing swampy areas, a slightly different milling technology can sometimes be used. In this case, after the first pass, the soil is immediately rolled. Further, the earth is milled a second time to the greatest possible depth.

On long and narrow sections, tillage using this technology is carried out in paddocks, starting from the middle. On large fields, the procedure is carried out according to a circular or curly technique with the obligatory observance of the turning radii in the corners.

Design of the milling machine

The main working part of such equipment is a drum with interchangeable working bodies. The FB-1.9 machine is very often used in swamp areas for the main tillage. The cutter frame is mounted on two wheels with crankshaft axles. The drum of this machine consists of 15 sections and rotates from the power take-off shaft of the tractor engine through the cardan shaft and gearbox.

Sections rotate during plowing and, when they meet an obstacle, they can turn and slide around their axis. This prevents the knives from breaking. Latest ineach section can be 2, 4 or 8. Also, the design of the drum includes a special coulter with dumpers. It is needed for processing, located under the bevel gear housing, a strip of soil (where the knives do not reach).

Behind the frame of such an aggregate for the main tillage, a grate of steel bars is suspended to hold large pieces of sod and plant residues. To deepen the working bodies in the machine, a special lifting mechanism is provided.

Knives in the drum can be installed several types:

- marsh;

- straight lines with a small bend for plowing virgin soil;

- field with hooks for lightly sod soils.

Soil rolling

The main task of tillage is, of course, loosening. However, quite often pre-sowing preparation of fields includes such an operation as soil rolling. This procedure is used to ensure that the arable layer is better moistened due to the capillary rise of water from the underlying horizons. Rolling also makes the soil surface more even, making it easier to plant.

On virgin soils and cleared of shrubs, intensive rolling is usually carried out, on waterlogged soils - light. In the latter case, such a procedure is sometimes not provided at all. Normally drained peat soils can be rolled both before sowing various crops and after planting.

Packing equipment

Perform this operation using specialrollers. Most often, water-filled two-link smooth equipment KVG-2.5 is used. Such a skating rink consists of two hollow cylinders with holes in the bottoms for pouring water. In front of this equipment, a frame welded from channels is installed. The weight of such a roller can be adjusted and can reach up to 4.5 tons.

Sometimes, lighter sober rollers ZKVG-1.4 can also be used for rolling. When completely filled with water, such equipment weighs about 0.97 tons.

Cultivation

Such types of work before planting crops are done quite often. During cultivation, the top layer of soil after plowing is loosened to a depth of up to 12 cm without turning the layer. The main purpose of this operation is weed control and additional loosening.

Loosening in this case can be carried out using cultivators of different types:

- paw;

- knife;

- spring;

- rod;

- wire, etc.

Also, cultivators are classified into tilled, universal and designed for special processing.

Recommended:

Analysis techniques: classification, methods and methods, scope

Today, among the analytical tools of business, a magnificent collection of methods and techniques of economic analysis has gathered. They differ in goals, grouping options, mathematical nature, timing, and other criteria. Consider the techniques of economic analysis in the article

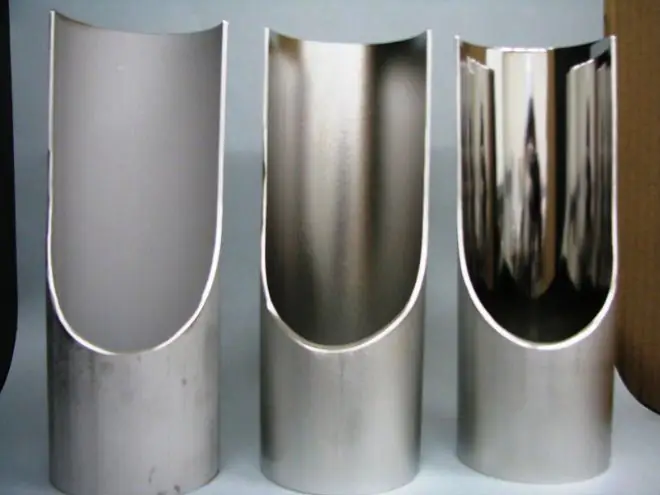

Stainless steel processing: popular techniques, methods and recommendations

Today, people use many materials. One of the most common is stainless steel. The material is characterized by high performance, and therefore has become so popular. In addition, the processing of stainless steel also helps to keep the metal in shape

Rules of negotiation: basic principles, techniques, techniques

This article will tell you about the ethics of business communication and the rules of negotiation. The main stages of negotiations, types of people's behavior and some principles of interaction with them will be described. Rules for negotiating on technical means of communication will also be presented

Meat: processing. Equipment for meat and poultry processing. Production, storage and processing of meat

Information of state statistics show that the volume of meat, milk and poultry consumed by the population has significantly decreased in recent years. This is caused not only by the pricing policy of manufacturers, but also by the banal shortage of these products, the required volumes of which simply do not have time to produce. But meat, the processing of which is an extremely profitable business, is very important for human he alth

Titanium processing: initial properties of the material, difficulties and types of processing, principle of operation, techniques and recommendations of specialists

Today, people are processing a wide variety of materials. Titanium processing stands out among the most problematic types of work. The metal has excellent qualities, but because of them, most of the problems arise