2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

In the process of extraction, transportation, storage and refining of oil, oil sludge is inevitably formed. Such waste contains a large amount of toxic compounds. Utilization of oil sludge is an urgent problem in the oil industry, as many enterprises store them on their territory for many years due to the lack of landfills for waste or the lack of processing facilities. Meanwhile, these substances can be used as secondary material resources that bring economic benefits.

Classification of oil sludge

Oil sludge is a complex mixture of heavy hydrocarbons containing a significant amount of oil products. The latter can be extracted in several ways and used for commercial purposes. The facilities where oil sludge is stored are divided into 2 types: oil sludge lakes, barns and reservoirs. In the first case, the substances are poured directly onto the ground, and the second - on a concreted area with clear boundaries.

Depending on the origin of oil sludge, they are divided into the followinggroups:

- appearing at the bottom of natural reservoirs after an accidental oil spill (bottom);

- formed in a mixture with drilling fluids during well construction;

- arising from oil refining;

- reservoir - consisting of liquid-viscous substances and gel-like substances formed on the walls;

- ground (when oil products get on the ground).

The chemical composition and content of mechanical impurities in oil sludge varies greatly.

Disposal Methods

The most common oil sludge disposal methods are as follows:

- chemical;

- biological;

- thermal;

- physical;

- physical and chemical.

The rational choice of this or that method is determined by the content of oil products in the sludge.

Chemical method

Chemical processing and disposal of oil sludge is carried out by the method of encapsulation and neutralization when reacting with alkaline earth metals (most often with quicklime). As a result of this process, a dry powdery substance is obtained in the form of small granules with a lime capsule. This product belongs to the 4th hazard class, that is, it is safe for the environment. It is used as a mineral additive in asph alt concrete and in the construction of earth embankments.

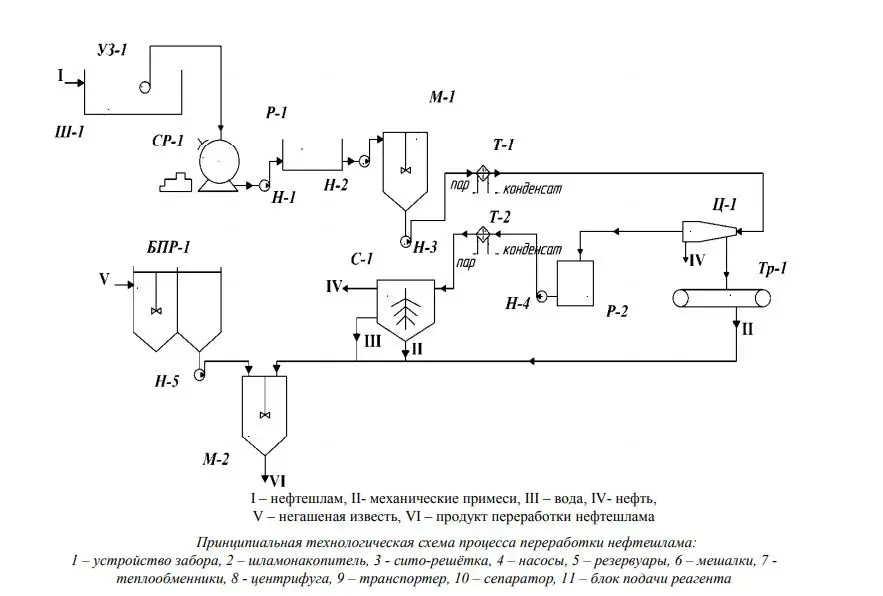

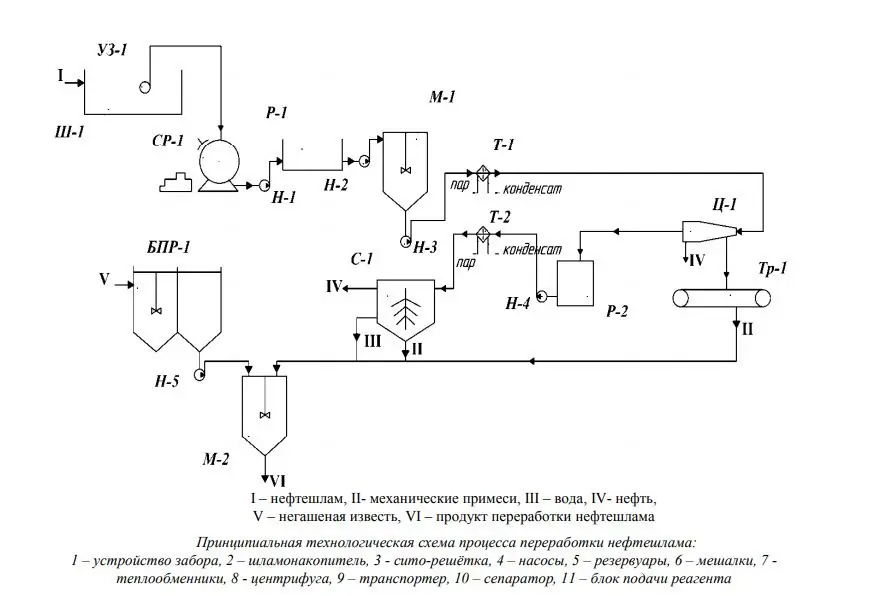

Schematic diagram of the oil sludge utilization plant for this technology is shown in the figure below.

Granules are characterized by high strength and tightness. The carbonization of their shells continues for several months. The disadvantages of this technology include the fact that it is necessary to use special equipment, a large amount of high-quality quicklime. The impact of the final product on the environment is also not fully understood. The advantages of chemical neutralization are relatively low cost and the possibility of manufacturing mobile units.

Biological technology

Biological decontamination is the most environmentally friendly method, but its use is limited to the treatment of those types of oil sludge that form in tanks, as well as spills on the ground or in natural water bodies. This is due to factors such as:

- high price of bioreagents;

- the need to allocate large tracts of land for landfills;

- possibility of neutralization in the field only in the warm season;

- high risk of soil pollution with heavy metals and other harmful substances.

The essence of the biological technology of oil sludge disposal is the use of microorganisms for the biodegradation of oil.

There is also a method of processing in a heated bioreactor. It is a chamber into which contaminated soil, water, fertilizers and beneficial microflora are supplied. As a result of creating favorable conditions, microorganisms multiply rapidly andthere is a stratification of the substance - oil products accumulate in the upper part of the reactor, and water - in the lower one. The remaining oil sludge is unloaded to drying sites. The duration of this process is 10-15 days, after which a new batch of secondary raw materials is fed into the chamber.

Thermal method

Thermal processing technology has several modifications:

- burning in ovens or open fires;

- dehydration or drying followed by return to production;

- thermal decomposition with lack of air (pyrolysis);

- gasification (oxidation of oil sludge to produce gas used as fuel).

Incineration is the easiest way to dispose of oil waste, but it requires cleaning and neutralization of flue gases, which cause significant damage to the environment. Drying is accompanied by high energy costs.

One of the most promising areas is continuous pyrolysis. Thanks to this processing, synthetic oil and pyrolysis gas are obtained, which are used as fuel for the same process. In this case, the equipment for the disposal of oil sludge is a plant, the main element of which is a pyrolysis chamber, in which thermal decomposition into fractions occurs at a temperature of about 500 °C. The released gas enters the filters and condensers, where it is cleaned.

When using an additional cracking system from oil sludgeYou can get quality gasoline. The unit is capable of processing all types of sludge, but from an economic point of view, it is more expedient to use solid waste oil products with a low degree of moisture.

Physical and physico-chemical methods

Physical methods of oil sludge disposal include the following fractionation methods:

- Simple settling. This is the least expensive and at the same time inefficient technology.

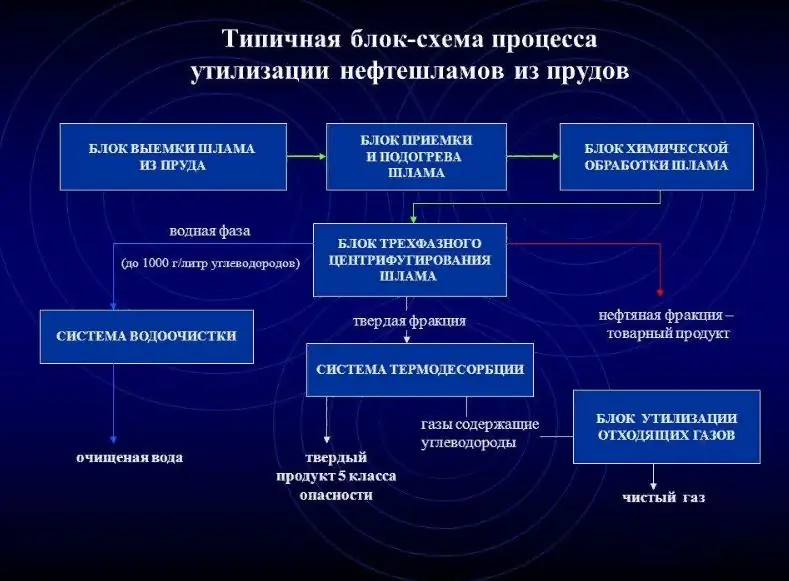

- Centrifugation. Centrifugal equipment is also often used at an intermediate stage in the preparation of oil sludge for their processing in other ways.

- Introduction of surfactants (demulsifiers, wetting agents, solvents).

- Filtering.

- Extraction with organic solvents, waste from the production of ethylene and acetylene, liquefied gases or steam. This method is based on the mutual dissolution of polar compounds.

The disadvantages of all the above technologies is the incomplete separation of oil products.

Recommended:

Oil is a mineral. Oil deposits. Oil production

Oil is one of the world's most important minerals (hydrocarbon fuel). It is a raw material for the production of fuels, lubricants and other materials

Utilization of oil sludge, removal and processing of oily waste

Oil refineries strive to optimize their technological processes as much as possible, reducing the volume of unused production products. But the thinner and deeper the processing of petroleum feedstock, the more dangerous the waste produced, which cannot be eliminated without third-party methods. One of the areas of recycling can be called the disposal of oil sludge as one of the most dangerous types of oily waste

Used oil recycling: equipment and methods of disposal

Full cycle production process with waste recycling minimizes the amount of environmental pollution. Against the background of the popularization of this approach in the industry, technologies for the specialized utilization of products of industrial activity are also emerging in order to form new raw materials. These processes include the processing of used oil, which results in fuel

Slurry is sediment. Drilling and oil sludge

Literally translated from German, this word means - dirt. Sludge is a sediment of solid small particles that is formed during the filtration or settling of a liquid. In addition, it can be a powder formed during the electrolysis of metals. As a rule, such sludge contains microparticles of precious metals. And finally, the sludge is obtained as a result of drilling or crushing of rock

How is oil produced? Where is oil produced? Oil price

Currently, it is impossible to imagine the modern world without oil. It is the main source of fuel for various transport, raw materials for the production of various consumer goods, medicines and other things. How is oil produced?