2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Centrifugal casting is a method of manufacturing blanks-castings, which is based on the action of centrifugal forces on the molten mass of material. The foundry, which is engaged in the manufacture of shaped blanks and rough castings, has a wide variety of casting methods: in a chill mold, in sand-clay molds, according to special lost-wax patterns, under the influence of pressure, etc. But in terms of the quality of the resulting casting, centrifugal casting is optimal.

In fact, the method consists in the fact that under the action of centrifugal force the molten material spreads evenly over the inner surface of the mold and, crystallizing, forms a workpiece with the necessary parameters. Do not think that this method is applicable only to metals and their alloys. In fact, molding of plastic products has become unusually widespread. But polymeric materials have a number of features that must be taken into account when working with them. Injection molding of plastics is often carried out under pressure, which ensures a special precision of products.

Mostlycases, different types of casting are used to obtain metal castings. At the same time, centrifugal casting has a number of advantages: the absence of hollow shells and slag inclusions in the resulting casting, high material density, increased metal wear resistance, which is achieved due to a uniform structure, etc. process (due to the maximum approximation of the casting to the finished product).

Centrifugal casting has a number of "minuses". These include: inaccurate obtaining of free surfaces of the workpiece, a tendency to segregation of the material, the high cost of molds (due to increased requirements for dimensional accuracy).

The centrifugal casting method uses special machines. They differ in the direction of the axis of rotation - vertical, horizontal and with an inclined axis (although the latter are used extremely rarely). Machines with a vertical axis are used to produce workpieces of small length with insignificant differences in steps (rings, pistons, bushings, etc.). Machines with a horizontal axis of rotation make it possible to obtain high-precision long-length castings with a wall of the same thickness. Cast iron pipes are obtained in a similar way. This method is the most common. With the help of centrifugal casting, it is possible to produce pipes with walls from 80 to 300 mm (depending on the equipment used). The only thing you should definitely remember is that with this method inworkpieces are subjected to internal stress. Therefore, after receiving castings, it is necessary to carry out annealing.

The method of centrifugal casting is also used to obtain other blanks for parts that are bodies of revolution. The high-precision casting method is especially popular in the manufacture of blanks from non-ferrous metals (this method saves expensive materials).

Recommended:

Hoskold method, Ring method, Inwood method - ways to recover investment capital

When a person invests his own money in an income-generating object, he expects not only to receive profit from the invested capital, but also to fully repay it. This can be done through resale or by obtaining such profits that not only bring interest, but also gradually return investments

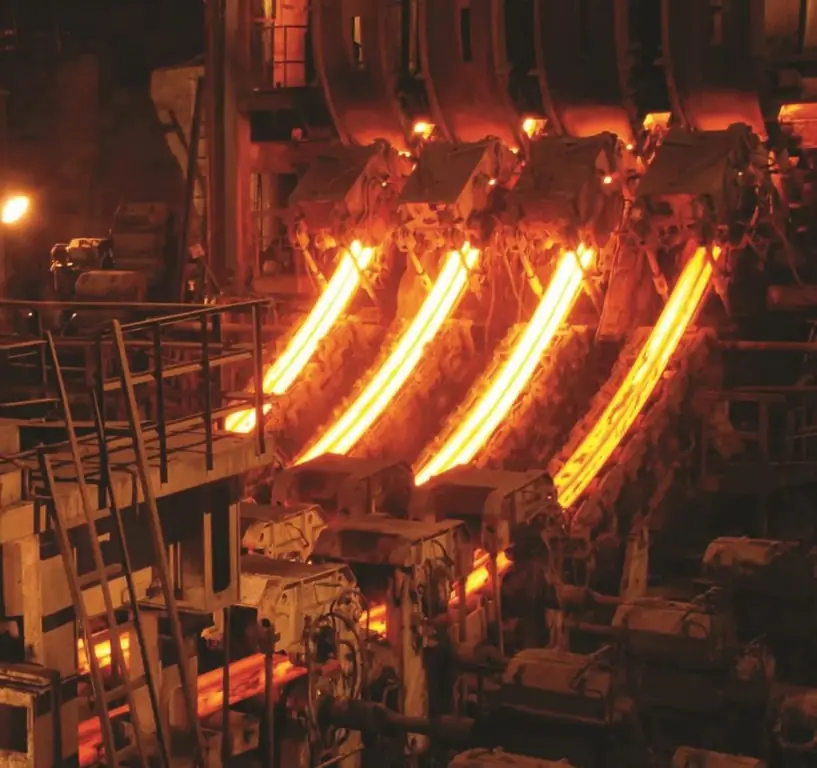

Continuous casting of steel: principle of operation, necessary equipment, advantages and disadvantages of the method

Today, a huge number of various things, parts, etc. are made of steel. Naturally, this requires a large amount of source material. Therefore, the plants have long been using the method of continuous casting of steel, characterized by the most important feature - high productivity

Casting in silicone mold: equipment. Vacuum casting in silicone molds

For the manufacture of a small number of plastic blanks, vacuum casting into silicone molds is most often used. This method is quite economical (making a metal mold requires more time and money). In addition, silicone molds are used repeatedly, and this also significantly reduces the cost of production

Diamond Drilling Rig: Precise holes in all materials

Construction and installation work is very often associated with making holes in concrete, stone and other similar hard materials. The diamond drilling rig is one of the most high-tech tools for their creation

Water household centrifugal pumps: market overview and manufacturer reviews

Modern household centrifugal pumps can be used in the organization of water supply to residential buildings and industrial premises, the construction of drainage systems, sewerage, etc. Their main advantages are excellent efficiency, high performance and low cost