2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Foreign inclusions, flaws, wood defects - all these flaws significantly reduce the quality of the material. Naturally, such raw materials will no longer be used for any construction purposes. For this reason, it is necessary to know what are the shortcomings of wood, as well as which ones and how to fix them.

General description of defects

First of all, it is worth understanding what, in principle, is classified as a wood defect. These are various kinds of imperfections that occur on the material due to exposure to weather conditions, mechanical stress, the presence of biological pests or any other factors.

It is also worth noting that these flaws do not always need to be fixed, it all depends on the purpose for which the material is used. Of course, in woodworking, such defects degrade the quality and complicate the processing process. In wood carving, for example, some flaws do not interfere with work at all, but according to artistic intentions, they can also be part of the pattern.

For these reasons, anyone who plans to work with wood needsknow what defects the material may have, which of them are dangerous and which are not. To begin with, it is worth understanding the general classification of wood defects:

- knots and cracks;

- deficiencies in the shape and structure of the trunk;

- biological and fungal flaws;

- foreign inclusions or chemical coloration;

- mechanical damage, warping, etc.

It is important to note here that mechanical flaws include not only those that were originally in the tree, but also those that may occur during processing, transportation, sorting, etc.

First type of flaw: knots

First you need to decide what it is. Knots are parts of branches, or rather their bases, enclosed in wood. However, not all so simple. To date, seven different types of such a deficiency are known. Types of wood defects:

- The first species is distinguished by its position. They can be plast, that is, facing the surface of a board or beam. They can be edge, that is, located on the edge of the board, they can also be rib or end. If the cross section of the knot goes through the entire cavity and is present at two ends at once, then it is stitched.

- They can differ, of course, in their form. There are round, oval or oblong.

- The degree of overgrowth also differs. Can be either overgrown or open.

- The degree of accretion is also distinguished separately. They can be either completely fused or partially. There are alsodrop type. This means that the knot is practically not connected to the surrounding wood.

- They can also be one-sided or through.

- Depending on the state of the wood, the state of the knots also changes.

Defects and defects of wood for the quality of lumber are the worst enemies. Sometimes knots are quite difficult to identify. For example, the horn type is distinguished by the fact that the tree itself is he althy, but some areas are heavily saturated with resin and tannins. Due to the resin, they have a darker color, as well as increased strength. However, if you dry a product with such a flaw, then the knot will simply fall out and a hole will form.

There may also be loose knots. This means that around them the tree is still he althy, but now they themselves are already starting to rot. At this stage, the knot may still be quite hard and retain its structure, but its color has already changed noticeably. A loose type of knot means that the material around is he althy, but a certain area has either completely or still partially lost its structure and is already too soft. The last type is a tobacco knot, which has completely lost its hardness and structure, has acquired a rusty-brown color that resembles tobacco and turns into powder almost immediately when touched.

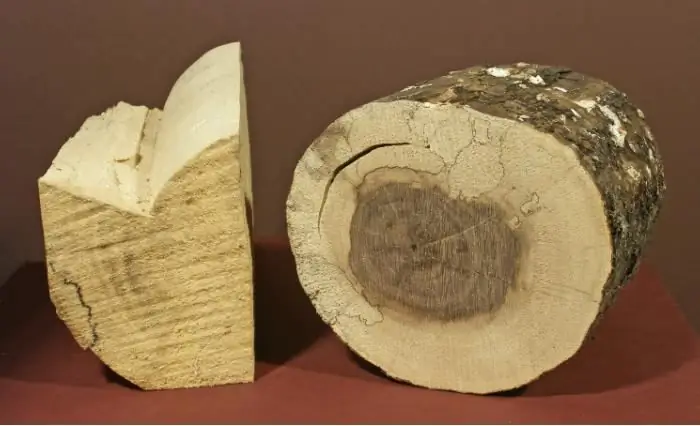

Second type: crack

A crack is a break in wood fibers along their location. Just like knots, they are divided into several types. They differ in their position, depth, width and type.

Such a defect in wood as a crack can be of a metic type. This type is characterized by the fact that one or several cracks pass inside the trunk through its core in the radial direction, but do not affect the periphery. Most often, such cracks go up from the butt. In addition, they tend to expand even further as they dry.

Frost cracks may occur. They are characterized by the fact that they also pass in the radial direction, but already from the sapwood into the core of the trunk itself. There is such a defect in wood, which is called a shrinkage crack. This means that cracks have appeared due to uneven drying of the material, which will increase, penetrating deep into the lumber.

Flaws in the shape of the barrel

In this case, all the flaws are natural and occur in the process of improper growth of the tree. They can also be of several different types.

The first defect in wood of this species is called buttstock. By this is meant a sharp and disproportionate increase in the diameter of the butt of the round lumber. Another downside is the sluggishness. This means that wood, on the contrary, decreases unevenly and not according to the rules in size, but rather in diameter. It is generally accepted that the normal drying out of a tree is 1 cm per 1 m of lumber. If the value is exceeded, then this is a flaw.

Another unpleasant drawback is the growth. This is the name of a sharp thickening on a tree trunk. The shape and size of such growths can be very different. Most often, this defect occurs in trees belonging to deciduous species. Naturally,that curvature also belongs to the defects of wood of this type. This is understood as the curvature of the axis of the lumber. Due to this shortcoming, the amount of waste is significantly increased during processing.

Longitudinal recesses in the butt of the trunk are called swarms. If you make a cut in such a part of the wood, then it will look like a star, and the location of the growth rings will be wavy. Most often, lumber obtained from such a tree, almost all goes to waste. This is because the material will warp too much, and strength will be greatly reduced.

Structure of a tree

Quite often it happens that the flaws and defects of wood lie in its very structure. Plus, there are quite a few of them.

Incorrect inclination of the wood fibers may occur. This means that some fibers do not run parallel to the longitudinal axis of the trunk. Such a slope can be of a radial or tangential type, depending on which angle. The presence of such a disadvantage greatly complicates the splitting process, as well as machining.

Another disadvantage is quite common in hardwoods and lies in the fact that the width of the annual layers of the tree increases significantly and locally. The occurrence of such a problem leads to the fact that it is necessary to dry the lumber more thoroughly, and this is fraught with the appearance of cracks.

It also happens that the fibers are arranged in a helical arc with respect to the longitudinal axis of the material. This is called a slant. Here it can be noted that it can be both of natural origin andartificial, if the logging is not properly dried. Most often, when such a defect and defect of wood occurs, it is strongly warped, which greatly complicates processing and increases the amount of waste. In addition, cutting such wood is much more difficult.

Sometimes there is such a thing as a tar pocket. Found in coniferous wood. This is the name given to the formation of small cavities between the fibers of the material, which are filled with resin. Due to their occurrence, strength deteriorates and processing is difficult.

Defects from pests and wood defects: a description of fungi

Many people know that during the growth of a tree, a fungus can occur inside its structure. Naturally, this is a disadvantage. The thing is that the fungus is the lowest form. This means that by itself it is not able to produce nutrients for its life activity. He gets them by sucking them out of a tree. Currently, all types of fungi are divided into two types: wood-staining and wood-destroying.

If we talk about the first group, then here we can include those pests that cause fungal heart spots or sap fungal stains. The second type of fungus is even more dangerous, since rot is the result of their effect on wood. It can also be added that some of the shortcomings are caused by the impact on the lumber of both types of fungus at once. The most favorable environment for their development is a temperature of 15-20 degrees Celsius and 30 to 60% humidity. When exposed to a temperature of 60 degrees, fungiare dying.

It is worth paying special attention to sap fungus coloring. It is important to note here that this drawback does not affect the mechanical performance of wood. However, the appearance of the workpiece is greatly deteriorating. In addition, the presence of such fungi on lumber always causes defects in the varnishing of wood. That is, when you try to paint or varnish the product, the layers will collapse when in contact with fungi. Everyone is quite familiar with mold and rot. It is clear here that in the presence of such flaws, the tree most often becomes simply unusable.

Eliminating knots and cracks

It is worth saying that in fact the formation of knots is not so scary as it might seem at first glance. Small intergrown knots will not cause trouble at all. Large and poorly held, most likely, they will simply fall out over time. After that, however, there will be a hole, possibly through, which will have to be repaired.

Sealing defects in wood in this case is quite simple. It is necessary to drill a hole in the workpiece, in the place where the knot fell out, but at the same time make it a few millimeters larger. From a board with the same thickness and structure, a “plug” of a suitable size is cut out, inserted into the hole and glued with wood glue. It only remains to add here that there may be something like a black line around some knots. This means that the wood is affected by rot, which will continue to spread. Such material is betteruse at all.

Cracks are wood defects. There are different ways to eliminate them. So, there may be several ways to solve the problem. If the crack is small, then it can simply be chipped or puttied. If the crack is large enough, then at present, a special sealant can be purchased on the building materials market, which can be used to glue the workpiece. Naturally, this is no ordinary sealant. The first thing that makes it significantly different is its compressive strength. Due to this, when lumber is deformed under the influence of high temperature, the substance is not squeezed out of the crack.

Wormholes and pitches

Elimination of wood defects, such as wormholes and pitch, is also real. As for the first problem, these are the moves that wood-boring insects make in the array. Detecting their activity is easy enough, as small holes will be visible on the surface.

The whole problem lies in the fact that the damage can be minor and then they do not interfere with the work, but can be quite serious, which will lead to a complete rejection of such a workpiece. Only a professional can determine what type of damage. If such holes are found in lumber blanks, then it is better not to buy them at all. If they are found in the walls, for example, of a wooden house, then you must immediately call a specialist who can treat the building with good antiseptics. It is impossible to delay with this, as these insects multiply very quickly.

Pitching most oftenoccur in places where the wood has been damaged by the tool. This greatly reduces its strength and degrades performance. There is no way to get rid of this shortcoming if it appears. This means that you need to be careful when processing wood so that they do not appear at all. This will be the best solution.

Fungus Elimination

The only sure way to protect wood from these pests is to treat it with antiseptics.

It is very important to note here that it is necessary to start covering the funds with protective equipment even before transportation to the construction site. The thing is that under suitable conditions, in just a couple of hours, the surface can turn blue. This means that a fungus has appeared. It will not reduce strength indicators, but it will greatly spoil the appearance.

This defect can be eliminated by using a special chlorine-containing compound as a bleach. To protect the wood during transportation, special "transport" antiseptics are used. They are valid for 2 to 8 months and are quite cheap.

Sufficiently long lasting protection formulations should be used after the materials have been delivered to the site or the building has already been erected. It is important to note that the blanks must be well cleaned and dried before they can be processed. Another important point is that the subfloor or logs, which are often in contact with moisture, need increased protection against fungus. Here you need to use a hard-to-wash preservative antiseptic.

The downside will be that the structure of the lumber will acquire a greenish tint, but there is no better protection. If this is not done, then the boards will simply rot and there will be no protection from this. Another important point is that it is worth processing not only the facade of the building. It is necessary to carry out the same protection actions inside the building, otherwise all work on protecting the outside will be in vain.

Mechanical defects and foreign inclusions

It also happens that defects occur during the drying of wood. This is called warping. This means that during cutting, drying, cutting or storage, the original shape of the workpiece has changed greatly. Because of this, the processing of wood is very difficult, since its shape usually becomes too curved. In general, mechanical damage is those flaws that already arise as a result of human interaction with wood blanks.

This includes defects that occur during cutting. Burns may appear on the wood, the cutter may accidentally cut the workpiece in an unnecessary place, etc. The presence of such defects greatly complicates the work of the cutter, since during processing it will be necessary to leave more material for allowances. Naturally, this increases the amount of waste and reduces the amount of usable material. Defects in wood processing most often lead to the fact that you have to refuse to use it.

As for foreign inclusions, then underthis implies the presence of stones, sand, glass, nails and other things inside the structure. Although it is fair to say here that with the exception of nails, everything else is quite rare. The presence of such inclusions entails not only the complication of the processing procedure, but also the risk of spoiling the tool during operation. In addition, the presence of inclusions such as nails causes discoloration around their location. This usually results in these areas simply having to be cut out.

As you can see, there are a lot of defects in wood processing. However, some of them can be eliminated quite easily, and the appearance of some can simply be prevented. For these reasons, this material is still common and widely used.

Recommended:

Wood waste: main sources of formation and types of disposal

Humanity is seriously faced with the problem of waste disposal, so all over the world are developing more and more advanced methods of waste disposal. Recycling is now such a fashionable foreign word. In developed countries, resource conservation is an important motivation for wood recycling. How is it in our country?

Wood processing technology and production of wood products

Wood is an unusual and especially valuable material. For all its familiarity, it has an amazing set of technical and physical properties that a person cannot repeat with the help of synthetic substitutes. This is due to the extensive use of blanks made of natural wood in a variety of industries. Modern wood processing technologies and the production of wood products in general make it possible to provide people with furniture, building materials, decorations, utensils, etc

The most valuable wood species: description, types and applications

For a long time, precious wood has been used by man for the construction of housing and ships, the manufacture of furniture and household utensils. Why not? After all, the material is distinguished by its reliability, beauty and natural warmth. Therefore, it is not at all surprising that in the conditions of modern production, natural wood of valuable species, described below, is actively used to form a wide range of products

Bread defects: photos, causes, baking problems and how to fix them

Bread making is a complex technological process. Not surprisingly, finished bakery products can have various defects. They can be caused by the poor quality of raw materials, the mistakes of the baker who kneads the dough and bakes it. It is worth noting that the flaws associated with the quality of ingredients are extremely difficult to fix, while technological flaws can be corrected. The article tells about the defects of bread and how to eliminate them

Defects of rails and their classification. Rail defect designation structure

Currently, people are actively using the railway. Delivery of various types of cargo by this route is the main type of transportation. However, due to the large weight of the trains themselves, as well as the cargo they carry, there is a strong pressure on the rails. Defects in these objects are a fairly common occurrence, which must be eliminated immediately