2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

Climatic equipment is largely dependent on cooling systems that can work according to different concepts. The general classification, in particular, distinguishes between air-cooled and water-cooled chillers. They differ in design execution and the nuances of the workflow. In this case, the air-cooled chiller will be considered, which is considered the most popular in this niche, although it also has many limiting nuances of operation.

What is a chiller?

From the point of view of functional content, a chiller can be understood as a refrigeration unit designed to lower the temperature of the working medium - usually liquid. But if we consider this equipment more broadly, then it will only play the role of an integral element in the overall technological process of work.climate system. This is not about local regulators, but about a large infrastructure that uses modular microclimate control software. One way or another, the main purpose of an air-cooled chiller is to generate artificial cold. In the future, the liquid or other process medium changed in temperature parameters can be used for other purposes. For example, in factories, cold water is used to prevent overheating of equipment. Conversely, the thermal energy from the generation of units can be converted into a power source for the chiller itself. But this principle of operation will be considered separately.

Implementation of air cooling system

The main function of an indirect temperature controller is performed by a capacitor. In its infrastructure, the main processes of selection of thermal energy, its transfer, accumulation, transformation and discharge take place. What exactly will be the set of tasks of the air condenser depends on its design and the place it occupies in the engineering infrastructure of the serviced facility. The basic principle of operation of an air-cooled chiller is to circulate the coolant through internal pipes that interact with the heat exchanger of the working medium. In other words, the merging of two environments (industrial warm and artificial cold) is ensured by design, as a result of which the necessary temperature balance is achieved. Specific cooling parameters in modernsystems can be point-controlled, since it is not always necessary to lower the temperature regime to critical values. But how is the generation of cold itself ensured? For this purpose, special refrigerants are used, the main of which is freon. It is a universal working substance, but propane, ammonia and halon active bases can also be used in industrial conditions to increase the efficiency of the process.

Air cooled design unit

The basis of the condenser is a system of finned metal pipes (usually aluminum), which just interact with the air of a particular temperature. Also, a cheaper and more practical bimetallic pipe structure with rolling ribs has recently been used. The outlet and inlet channels may have different capacities depending on the capacity of a particular air-cooled chiller. Capacitors with a double outlet section, for example, can reach a power potential of 3 MW. Universal modular installations, which are also used in the private sector, rarely exceed 100 kW in this indicator. The design also includes a housing block of a suitable format, means for communication strapping and mounting hardware for introducing equipment into the climate network.

Varieties of air-cooled chillers

The main feature of the division of chillers is the type of construction. By thisclassification distinguish the following types of device:

- With centrifugal fan. They are installed indoors, but later they work with outdoor air coming from the street through air ducts.

- With axial fan. Used outside, directly carrying out a fence from the street. Communication with a functional climate system is provided through communication channels going through mounting holes through the walls.

- With remote condenser. If the two previous systems provide for monoblock execution of working components, then in this case the functional unit is located in the room, and the condenser is outside. The chiller configuration with a remote air-cooled condenser has its advantages not only in terms of performance and technological energy efficiency, but also as a convenient base for improving individual modules, which is not provided for in monoblock systems.

Features of Absorption Air Chiller

A purely industrial type of chiller, the feature of which is the use of technological waste energy as a source of energy supply in enterprises. First of all, it should be emphasized that many modern factories emit thermal energy, technical hot water and other production and energy resources in the form of waste. In turn, undergoing a throttling operation, hot streams can be used as an active medium for sorbents. In chillers with aircooling of the condenser, it can be a water-ammonia solution, which further gives energy to the generator set. As a result, a heat conversion cycle is organized into the power source required for the chiller. If earlier this cycle provided for the presence of a mini-station for converting thermal energy into electricity, then in absorption equipment this function is performed in a natural format without intermediate systems.

Equipment operation

After the installation is completed, the operator fills the communication channels with refrigerants and checks the condition of the measuring and control equipment. Typically, control includes an input switch, a fan speed controller, a protective device, a controller relay, etc. In an industrial infrastructure, an air-cooled chiller can be serviced from a control room, where the temperature of the coolant, pressure, pump status, air flow, refrigerant characteristics, etc.

New Chiller Technology

Despite the simple arrangement of the heat exchange infrastructure, modern design solutions regularly improve the technical and operational qualities of this equipment. For example, Aquaflair's ERAF0621A air-cooled chiller with a pair of double-scroll fans provides highly accurate temperature settings down to 0.2°C. The intelligent microprocessor control system also expandscontrol and emergency protection capabilities, leading to the responsible use of such systems in hospitals, hotels, office buildings, etc.

Conclusion

The chiller is the optimal solution to the problem of maintaining the temperature balance in microclimate control systems. It is not a stand-alone piece of equipment, but its function is extremely important in many areas where precise control of heat energy from air conditioners is required. But how economically does such an addition justify itself? An example is the air-cooled chiller Carrier 30RBM 160 from the high-tech AquaSnap series. Its cost is about 3 million rubles, not to mention future electricity costs. However, compared to alternative refrigeration units with a similar power level up to 100 kW, this unit will benefit from environmental friendliness, ease of operation and functionality. In addition, technical and installation flexibility will reduce the cost of custom design with many design possibilities.

Recommended:

Glass furnace: types, device, specifications and practical application

Today, people actively use glass for a variety of purposes. The glassmaking process itself is the melting of raw materials or charge. Glass melting furnaces are used to melt the material. They come in different types and are classified according to several criteria

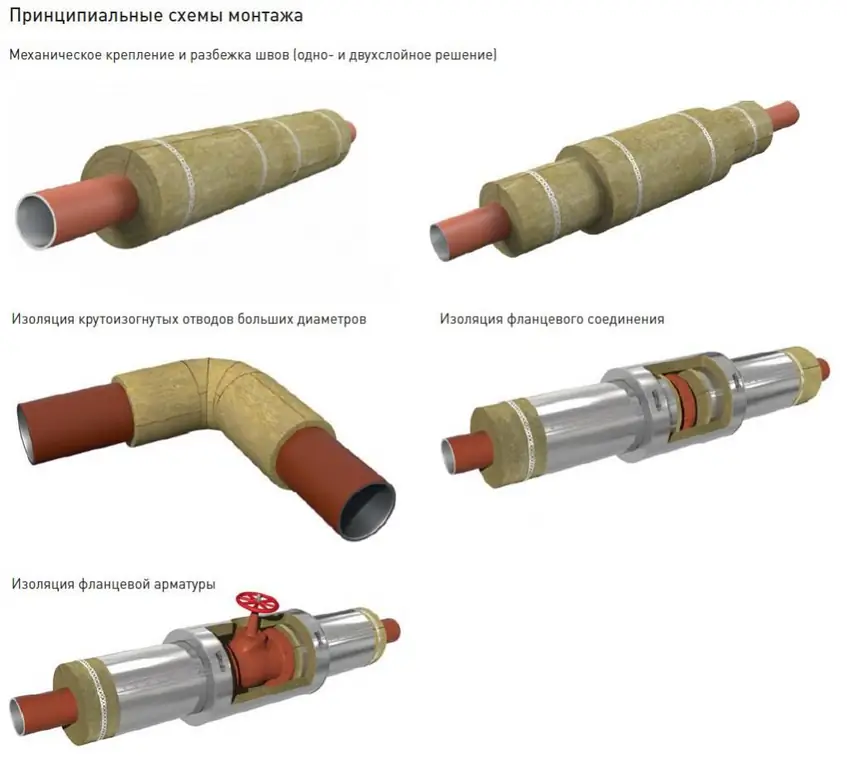

Cylinders "Rockwool" (Rockwool): description, device, principle of operation, application, photo

The service life of pipes is reduced due to their use in conditions of low temperatures and high humidity. This problem, however, can be solved by using modern protective materials made of mineral wool. Among the huge variety of proposals on the market, Rockwool cylinders are not the last. The company started its activity more than a century ago in Denmark. During its existence, it has achieved consumer recognition

Classification of machines: types, application, device

Classification of machines: types, design features, pros and cons, photos. Classification of grinding, metal-cutting and milling machines: device, purpose, application. Classification of machine tools for metal: description, characteristics

General purpose engines: device, principle of operation, application, photo

Automotive equipment is mainly equipped with standardized internal combustion engines (ICEs), the design of which is focused on placement in the engine compartment. However, there is a great demand for power units of this kind in the garden equipment segments, from manufacturers of snowplows, snowmobiles, etc. Moreover, the requirements for integration and operational parameters in such cases differ sharply from automotive standards

Main busbar: description, types and device, application

Power supply wiring in manufacturing plants and construction sites needs additional protection. Conventional insulation does not always cope with these tasks, so special circuits are used that also perform the functions of distribution and optimized connection. A typical version of such wiring is a trunk bus duct containing one or more power lines