2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:32

Plexiglas engraving is considered a painting craft. A souvenir figurine, stained-glass windows or a glass table, which are decorated with exquisite drawings, embody a delicate artistic taste. Pickling and sandblasting technologies are in the past. Today, with the help of a laser machine, everyone can create a highly detailed pattern.

Laser glass engraving technology

Today, laser machines are the most high-tech equipment. The thickness of the laser beam is 0.01 mm, which makes it possible to create art pieces on glass. In this case, it does not matter whether the drawing consists of a large number of tiny elements, complex micro-patterns, or it is solid.

Engraving on plexiglass using specialized laser machines is of high quality, so it is popular in various fields of production.

To operate such machinesnot difficult at all. The control is completely built on numerical control, it is computerized from beginning to end. It is easily handled by one competently trained employee. Special LaserCut software and graphic editors apply drawings of various configurations to plexiglass.

It is worth noting that the laser beam can engrave both flat glass surfaces and convex ones. Working on laser machines becomes easier and easier due to the fact that the tasks that have been done before are entered into the large memory of this equipment.

Benefits

Laser engraving on Plexiglas has a number of advantages. One of them is that only this method is able to convey the tiny subtleties of the original sketch. The result depends only on him. Plus, it is a fully automated process, and since there is no manual labor, the order is completed as soon as possible.

It is these advantages of engraving plexiglass with a laser that made it popular and gave the prerequisites for mass production.

Let's look at what can be decorated with laser engraving:

- signboards and plates;

- auto glass;

- furniture;

- interior doors and closets;

- vases, glasses, bottles, mugs, glasses and cups;

- paintings and photographs on glass;

- all kinds of souvenirs;

- cups, prizes and more.

With the help of this method, each decorated item will become unique and unusual. Illuminated plexiglass engraving is a great solution for decorating advertising signs. In this case, lamps are installed at the end of the illuminated object. As a result, the light is reflected from the walls and evenly distributed over the entire area of the sign. If there is an engraving on the plexiglass, then its lines refract light, thereby the image will glow. As a result, the illuminated engraving looks much more expressive and beautiful. Such advertising is perfectly visible both day and night.

Types of laser engraving on glass

Plexiglas engraving includes a large number of options, so that everyone can choose something suitable for themselves. The method of applying text or drawing is selected depending on:

- material;

- image quality and size;

- required detail.

There are the following types of engraving:

- Classic on glass.

- Inside the glass. In this case, 2 lasers are used. The glass remains smooth on both sides, the pattern is created in its very thickness.

- Engraving. This species has size restrictions - 10 x 10 centimeters.

- 3D. In this way, you can quite accurately apply the image inside the object without violating the integrity of the canvas.

- Diamond. Great for drawing vector images and texts.

Conclusion

You can engrave with a laser various glasses: mirror, crystal, sheet, polished,pressed, cast and container. Due to the flexible laser technology, images and inscriptions can be applied to various spherical glass objects. To a greater extent, the cost of such engraving inside glass depends on the amount of work. Laser engraving on plexiglass is a versatile option for all occasions because it provides ample scope for imagination and results in great work. Such products can be an excellent gift or home decoration.

Recommended:

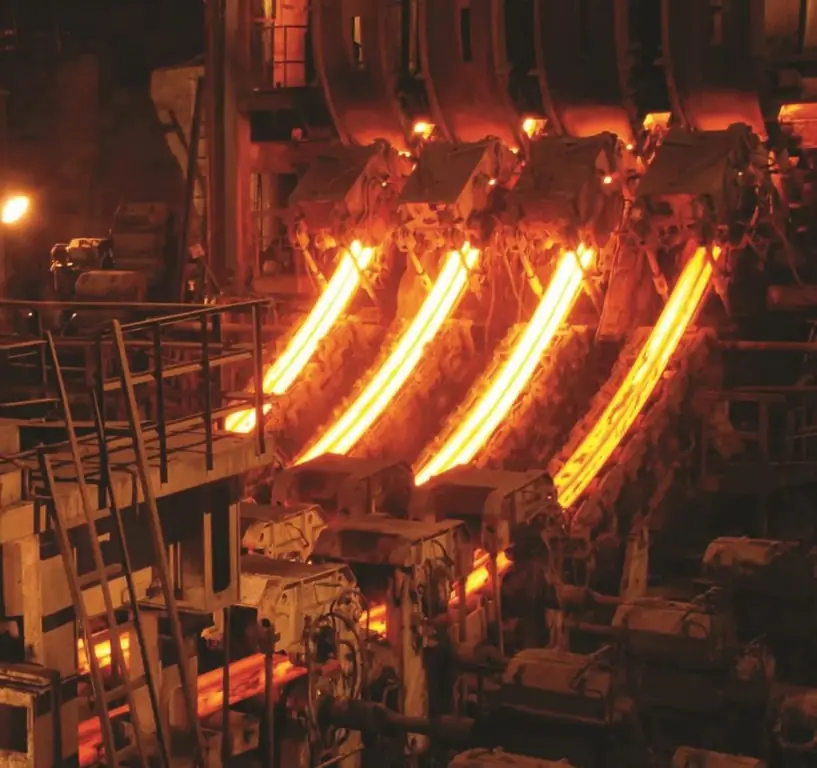

Continuous casting of steel: principle of operation, necessary equipment, advantages and disadvantages of the method

Today, a huge number of various things, parts, etc. are made of steel. Naturally, this requires a large amount of source material. Therefore, the plants have long been using the method of continuous casting of steel, characterized by the most important feature - high productivity

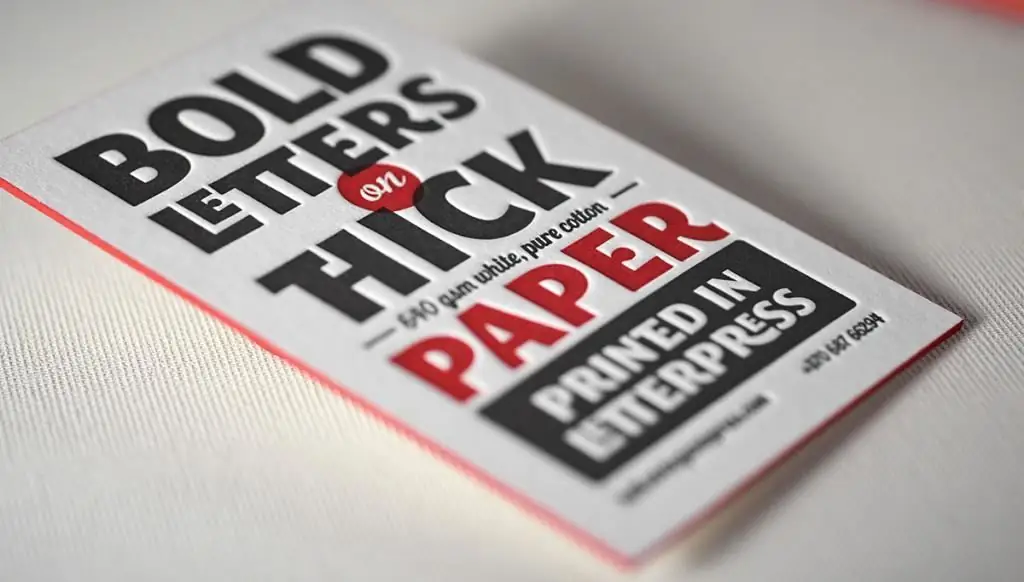

Letterpress is Letterpress printing technology, modern stages of development, necessary equipment, advantages and disadvantages of this type of printing

Letterpress is one of the typical methods of applying information using a relief matrix. The elements that protrude are covered with paint in the form of a paste, and then pressed against the paper. Thus, various mass periodicals, reference books, books and newspapers are replicated

Ultrasonic processing: technology, advantages and disadvantages

The metalworking industry at this stage of development is capable of solving the complex tasks of cutting and drilling workpieces of varying degrees of hardness. This became possible due to the development of fundamentally new ways of influencing the material, including a wide group of electromechanical methods. One of the most effective technologies of this type is ultrasonic treatment (UZO), based on the principles of electroacoustic radiation

Laser engraving on plastic: types of plastic, choice of pattern, necessary laser equipment and patterning technology

What types of plastic are used when applying laser engraving. Designs suitable for engraving and their types. How to edit and prepare photos for laser engraving. Necessary equipment for work, principles of its operation

Lost-wax casting: technology, advantages and disadvantages

The use of investment models is a fairly popular method of foundry production. It is used where it is necessary to accurately observe the dimensions and ensure high quality of the surface of the parts. This is how turbine blades and high-performance tools, dentures and jewelry are cast, as well as sculptures of complex configuration. The mold for casting is one-piece, the model of low-melting materials is not removed during molding, but is melted out