2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

An uninformed person believes that the main structural material of our time is iron. Those who understand know that the word "iron" refers to iron-carbon alloys - steel and cast iron. It would seem that two completely different materials and they are very easy to distinguish. However, given the wide range of their species and brands, it is difficult to determine the fine line of difference in the chemical composition of some of them. It is important to have additional skills in order to know the answer to the question: what is the difference between cast iron and steel?

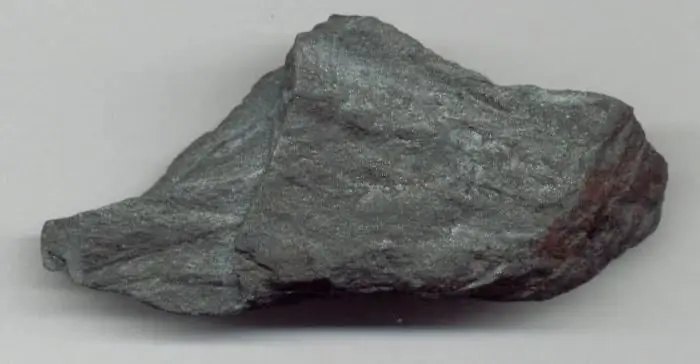

Cast iron

An alloy containing iron, carbon in the amount of 2, 14-6, 67, sulfur, phosphorus, manganese, silicon and other additives is called cast iron. The history of smelting began in the Iron Age. An important structural material, the basis of metallurgy and the entire steel industry.

Features:

- Rough, matte graycolor.

- Melting at 1000-1600˚С depending on the composition (for industrial, on average - 1000-1200˚С, white and pig irons melt at higher temperatures).

- Density: 7200-7600 kg/m3.

- Specific heat capacity: 540 J/(kg˚C).

- High hardness: 400-650HB.

- Low ductility, very crumbly under pressure; malleable ductile cast iron δ=6-12%.

- Low strength: 100-200 MPa, for malleable it reaches 300-370 MPa, for some grades of high-strength - 600-800 MPa.

- Modeled using heat treatment, but rarely and with great care, as it is characterized by a cracking process.

- Doped with the help of auxiliary chemical elements, however, a significant degree of alloying further complicates the technological processing.

- Characterized by satisfactory weldability, good machinability, excellent casting properties. Not subject to forging and stamping.

- Good wear and corrosion resistance.

Cast iron is a material for body parts, blocks, machine components made by casting. It is the main charge component for steelmaking.

Steel

A carbon-iron alloy containing no more than 2.14% carbon and no less than 45% iron is called steel. Its main features are:

- Smooth, has silvercolor with a characteristic reflection.

- Melting within 1450˚C.

- Density is between 7700 and 7900 kg/m3.

- Heat capacity at room temperature: 462 J/(kg˚C).

- Low hardness, average 120-250 HB.

- Excellent plasticity: elongation δ ranges from 5-35% for various grades, δ≧20-40% for most grades.

- Average tensile strength for structural materials - 300-450 MPa; for especially strong alloyed - 600-800 MPa.

- It lends itself well to the correction of properties using thermal and chemothermal treatments.

- Actively doped with various chemical elements to change properties and purpose.

- Quality high weldability, pressure and cutting performance.

- Characterized by poor corrosion resistance.

Steel is the main structural alloy in modern metallurgy, mechanical engineering, instrument making and technology.

Determining origin by part type

Having considered the detailed characteristics of these alloys, you can confidently use the knowledge of how cast iron differs from steel. Having a metal object in front of you, doubting its origin, it is rational to immediately recall the main distinctive technological properties. So, cast iron is a casting material. It is used to produce simple dishes, massive pipes, machine tool cases, engines, large objects of a simple configuration. Fromsteels produce parts of all sizes and complexity, since forging, stamping, drawing, rolling and other methods of metal forming are used for this. Thus, if there is a question about the origin of reinforcement, there can be no doubt - it is steel. If you are interested in the origin of a massive cauldron - this is cast iron. If you need to find out what the engine housing or crankshaft is made of, you should resort to other recognition options, since both options are possible.

Color features and fragility analysis

In order to know how to distinguish cast iron from steel by eye, you need to remember the main visual differences. Cast iron has a matte gray color and a rougher outer texture. Steel is characterized by its special silvery lustrous hue and minimal roughness.

Also important knowledge on how to distinguish cast iron from steel visually is information about the ductility of these materials. If the investigated workpieces or metal objects are not of serious value, you can test them for strength and ductility by applying impact force. Brittle iron will crumble into pieces, while steel will only deform. With more serious loads aimed at crushing, cast iron crumbs will turn out to be small in various shapes, and pieces of steel will be large, of the correct configuration.

Cut and drill

How to distinguish cast iron from steel at home? Necessaryget fine dust or shavings out of it. Since steel has high ductility, its chips also have a tortuous character. Cast iron, on the other hand, crumbles; when drilling, small chips of fracture are formed along with dust.

To get dust, you can use a file or rasp and sharpen the edge of the part of interest a little. Consider the resulting fine shavings on your hand or on a white sheet of paper. Cast iron contains carbon in large quantities in the form of graphite inclusions. Therefore, when rubbing its dust, a black graphite “trace” remains. In steels, carbon is in a bound state, so the mechanical effect on dust does not give any visible results.

Heat and sparkle

How to tell cast iron from steel? You need to operate with the necessary equipment and a little patience.

In the first case, you can resort to heating, for example, with a blowtorch, initially dressed in special protective clothing and observing safety rules at work. The temperature must be raised before the metal begins to melt. It has already been said that the melting point of cast iron is higher than that of steel. However, this applies mainly to white and pig irons. Regarding all industrial grades, they contain carbon in an amount of not more than 4.3% and melt already at 1000-1200˚С. Thus, it can be melted much faster.

An informative method of obtaining information about how cast iron differs from steel is to use an experimental sample on a grindingmachine or under the sharp wheel of a grinder. The analysis is carried out according to the characteristics of the sparks. Cast iron is characterized by dim red sparks, and steel is characterized by bright blinding short rays with a white-yellow tint.

Like it sounds

An interesting feature is how to distinguish cast iron from steel by sound. The two alloys sound different. It is not at all necessary to produce musical accompaniment on the available experimental objects. But it is necessary to have both samples or to have an experienced ear in this matter. Steel is characterized by a higher density, which is reflected in its sound. When hitting it with a metal object, the sound is much more sonorous than in the same situation with cast iron.

In order to know how cast iron differs from steel, you need to have a little knowledge about these materials and some experience. After all, an experienced professional in the field of forging, grinding, milling, drilling, turning, heat treatment or welding, a metallurgist or a technician can easily distinguish them from each other, evaluating only visually or by touch.

Recommended:

Food stainless steel: GOST. How to identify food grade stainless steel? What is the difference between food stainless steel and technical stainless steel?

The article talks about grades of food grade stainless steel. Read how to distinguish food stainless steel from technical

How to cook cast iron by electric welding: work technology and necessary materials

The main composition and types of cast iron. Difficulties and features of welding cast iron products. Cast iron welding methods. Preparatory operations before welding. How to cook cast iron by electric welding in a cold and hot way, as well as gas equipment. Features of the electrodes used for welding cast iron. Safety measures during welding

Diameters and dimensions of cast iron sewer pipes. Types and features

Cast iron pipes are used today in the laying of external and internal sewerage systems. Products can be channelless and channel. Their service life can reach 100 years. Connecting elements and assortment of sewer pipes is determined by GOST 6942-98. After reading the documentation, you will be able to understand what parameters the pipes should have

Alloy cast iron: grades, properties and applications

Alloyed iron is a material that is produced by smelting in blast furnaces. It can contain different amounts of carbon. Depending on the quantitative content of this substance, two types of cast iron are distinguished. The first is called conversion, or white, and the second is gray, or foundry

Types of cast iron, classification, composition, properties, marking and application

The types of cast iron that exist today allow a person to create many products. Therefore, we will talk about this material in more detail in this article