2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

Manufacturing companies care not only about how to make a product, but also about how to store and transport it. During transportation, paper packaging, containers made of glass, plastic or stainless steel should not be damaged. In this case, a shrink machine is a must at the enterprise.

Sealed packaging

Different groups of goods have their own rules for storage and transportation. With a shrink wrapping machine, you can create optimal conditions to preserve the freshness of products and their appearance. Third-party objects and dirt do not get to the goods. The volatilization of components is reduced to a minimum. Packed items are much better protected from mechanical damage. It is thanks to the shrink machine that a tight fit of the goods with packaging material is created. With its help, even objects with complex shapes can be densely packed into a fairly dense shell.

How the machine works

The name itself already contains the answer to the question of how the device functions. The wrapping material is loaded into the machine, under the influence of high temperature it shrinks and shrinks, thanks tothis object fits snugly.

The work uses different films: polyethylene, polyvinyl chloride and others. Items can be packaged individually or individually. It is possible to pack items of different shapes and sizes. Enterprises purchase shrink wrapping machines that are suitable for sealing manufactured goods.

Hand wrapping machines

Technique is different, but in this case there are different modifications that allow you to work in several modes. In any production, such a unit will become simply an indispensable assistant. For example, a manual shrink wrapper can seal 300 packages in an hour.

For small businesses, this is a great option, it is relevant if you need to work with small products. Such a device is suitable when high speed is not required. All actions are performed in manual mode, and the machines have a control unit with electromagnetic locks and memory for 6 programs. This makes it possible to increase the speed of the operator.

Semi-automatic machine

Semi-automatic heat shrink machine can pack 1200 packs per hour. This option is relevant for medium-sized businesses if the packaging process is not integrated into the production flow. The electronic system in different models gives a small gap to regulate the speed of work. Some sealers process 800-900 packs.

Automatic packaging

Devices powered byautomatically, can be fully integrated into production processes. 3000 packages per hour can be processed by shrink machines operating in automatic mode. There are different models, they have their own characteristics and are selected according to the product with which the manufacturing company works.

Speed automatic packaging

There are different models of shrink machines on sale. Sealing on these units allows you to preserve the presentation and protect even soft and fragile objects from damage. In work, you can use a dense film, heat shrinkage provides food products with long-term storage. Operation speed can be adjusted from 4200 to 8000 packs per hour.

Any machine with these characteristics is built into production lines with full automation of work. Side sealers allow processing 6000 packs per hour. Sealing the film always forms a longitudinal seam on the side. For example, let's take a sealer from Overlapping. In an hour, the unit can process 8000 packages, while at the bottom of the package an almost imperceptible seam is formed.

Choice of the unit for work in the food industry

When working with each product, it is worth choosing models that correspond to the tasks of the enterprise. The food industry has a number of regulations that apply only to this area. Increased requirements are imposed on the storage and packaging of goods. To work in this area, you should choose stainless steel heat shrink.

They are mainly used for packing meat, fish, poultry, cheese and vegetables. They are also used to process sweets, cookies, chocolate and bread products. The body of the machine is made of high quality stainless steel. Product transport belts are made from materials that meet the requirements for handling products in this category.

Features of heat shrink machines

As already mentioned, there are different devices, they are distinguished depending on how they are used. In semi-automatic machines, the operator wraps the product in a special film and places it for soldering in an appropriate way. Refueling, the movement of packaging through the tunnel shrink machine takes place without the intervention of workers. In automatic machines, the operator's actions are limited to selecting the desired program and entering it. The employee only controls the overall process. The machine has sensors, thanks to which it is possible to enter the production line.

Using a special film at work

Packaging of goods at enterprises is carried out using a film for a shrink machine. A versatile and economical material due to its properties can be used in completely different industries: food industry, cosmetics, etc. With strong heating, polyvinyl chloride is compressed along two axes. Thanks to these properties of the packaging material used, it is possible to achieve complete tightness. It is valuable both during storage and during transportation.

When packing small parts, they can befix in a dense frame so that each of them remains in its place. If the product is colorful, then such storage protects it from fading and fading of colors. Packaging film is widely used for sealing household chemicals, stationery, printing products. Such dense packaging allows you to protect the goods from opening. With medicines and goods for children, this is very important. Packaged products are more trusted by the consumer.

Recommended:

Large-caliber machine guns of Russia and the world. Comparison of heavy machine guns

Even in the First World War, a fundamentally new and terrible weapon appeared on the battlefield. Large-caliber machine guns. In those years, there was no armor that could protect against them, and the shelters that were traditionally used by the infantry (made of earth and wood) generally made their way through with heavy bullets

Double-deck cars from the Tver Carriage Works are planned to be used on Russian railways

Russian-made double-deck cars were presented by the Tver Carriage Works (TVZ) back in 2009. The timing of the introduction of "giants" into mass operation is still vague. Russian Railways has already expressed its approval, and tests will show whether it is advisable to put double-deck cars into operation. They may be most in demand on routes from Moscow to St. Petersburg, Minsk, Kyiv, Bryansk, Kursk, Belgorod, Voronezh, Kostroma, Novgorod, Kazan

RPK-16 machine gun: specifications. Kalashnikov light machine gun

At the international presentation of weapons "Army-2016", held in September 2016, the RPK-16 machine gun, the brainchild of domestic gunsmiths, was demonstrated. It will be discussed in this article

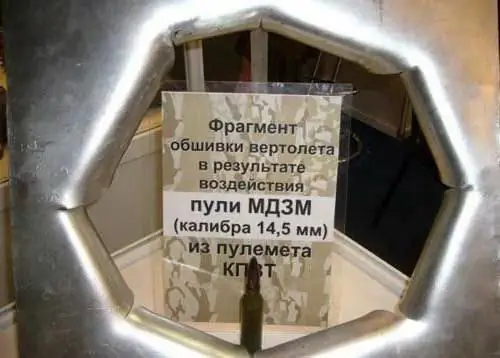

KPVT, machine gun. Heavy machine gun Vladimirov KPV

The idea of defeating aircraft and lightly armored vehicles led to the creation of heavy machine guns with a caliber of more than 12 mm. Such machine guns were already able to hit a lightly armored target, get a low-flying aircraft or helicopter, as well as shelters behind which there was infantry. According to the classification of small arms, the 14.5-mm KPVT machine gun is already adjacent to artillery weapons. And in design, heavy machine guns have much in common with automatic guns

How an electric differential machine works

The electric machine is designed to instantly de-energize the entire electrical circuit or that branch of it in which an unsafe situation has arisen. In order for it to complete this task, a simple processing of information is necessary