2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:30

The engraving machine is used to apply a three-dimensional texture to the surface of metals, plastics, wood and glass. The equipment is selected according to size, structural rigidity, multitasking and the number of axles. Part programs are entered through the standard coding procedure through the machine interface.

Why choose automated equipment?

The CNC engraving machine is able to provide high performance and dimensional accuracy of the final product. The proposed additional software allows you to quickly create 3D models of parts and debug without rotating the spindle assembly. The virtual run of the program allows you to avoid operator errors and make adjustments before an emergency occurs.

Modern models allow you to perform all stages of creating a future part directly on the screen of the CNC system. Such an engraving machine already has a hard drive with an operating system installed. At the same time, applications for creating machine codes are integrated into the latter throughreading a 3D drawing.

The engraving machine is chosen by manufacturers of cabinet furniture, metal jewelry, plastic patterns, and even dentists. Dental prostheses, fillings, crowns are made with high precision using the latest equipment presented, which reduces the cost of the final cost of the goods.

Portable models

CNC engraving machine is used more often as a universal equipment, so its mobility is required. Portable and lightweight models are in demand by automotive service companies for the manufacture of unique high-value parts. Such machines can be placed for transportation in the trunk of a car, and in the workshop - on any flat surface. Power is supplied from a regular household outlet.

The CNC engraving machine has a lightweight aluminum profile, which makes the structure light and strong at the same time. The dynamics of the latest versions of engines allows you to produce any sample in a matter of minutes, the customer will be satisfied with the prompt assistance. A complex detail can be made even in the field, having a fuel generator with you.

Hardware Features

CNC engraving machine experiences mechanical stress during cutting, therefore, when choosing equipment, they are guided by the strength of the structure in relation to the workpiece. 3D machining is done thanks to 5-axis versions, and simple figures are turned without the use of cooling by 3-axis systems. Cutting speed and memory capabilitieslaid at the request of the customer.

A USB interface may also be present, which is often an option at the time of purchase. The CNC engraving machine requires careful and competent handling. If the manufacturer's requirements are not met, the machine can easily break down when the cutter cuts into the workpiece at high speed.

Impact protection is not always present in serial versions of machines. If a manufacturer decides to produce high quality products with an original texture, then he will, of course, choose an engraving machine. The price of the product varies from several thousand to millions of rubles. It is worth consulting with experts in this field to save yourself from unnecessary expenses.

Contactless processing

Recently, more and more often choose a laser engraving machine. It has undoubted advantages over contact types of processing. In terms of speed, it is in no way inferior, but there is a significant savings on the purchase of a tool.

Laser engraving machine is much more expensive, but it pays for itself much faster than contact equipment. Spending is justified due to the increase in sales of the goods received with its help. The contours and lines of the part are completely different in appearance. They turn out smoother without mechanical damage.

Laser cutters are capable of cutting material of a certain thickness. For cutting denser workpieces, an additional laser pass is required. Additionally, machines can be equippedvibroknives designed for cutting sheet materials. The use of such options is justified for accurate machining and precision products.

Applications

Engraving machines are more often required for cutting sheet materials in the furniture industry and for making patterns on thin long products. So, on the packaging of any product, it is required to apply a special pattern that attracts the buyer with its originality. The label of any product acquires unique forms using CNC systems. This is how the gold stamping of the pattern on the foil is carried out.

Modern product becomes uncompetitive without proper decoration. It is now rare that even an ordinary simple product is sold in a package without a fancy-shaped pattern. Entire landscapes, paintings and inscriptions are applied on microscopic details. CNC systems help to make the packaging of any product attractive. This is used by manufacturers of aperitifs, soft drinks, dairy products. The applied image is a kind of quality mark, protection against counterfeit goods.

Mistakes when choosing

No matter how simple the production process of any part may seem, the process from the beginning of the design of the form to the actual cutting cycle is very long. Here you have to take into account a huge list of factors, conditions and parameters that affect the demand for products. The quality of parts depends on the rigidity of the machine, the cycle and processing mode, the type of cutter and engraver.

Often buyers are faced with the problem of upgrading equipment, when some time ago a low-power machine was bought, and then it was necessary to produce parts with slightly oversized characteristics. It becomes very unpleasant when there is not enough stock in the machine. Therefore, always choose a CNC machine model with twice the rigidity in case of emergency situations and the possible processing of a heavier part.

Recommended:

Large-caliber machine guns of Russia and the world. Comparison of heavy machine guns

Even in the First World War, a fundamentally new and terrible weapon appeared on the battlefield. Large-caliber machine guns. In those years, there was no armor that could protect against them, and the shelters that were traditionally used by the infantry (made of earth and wood) generally made their way through with heavy bullets

Plexiglas engraving: advantages and disadvantages, technology, equipment

Plexiglas engraving is considered a painting craft. A souvenir figurine, stained-glass windows or a glass table, which are decorated with exquisite drawings, embody a delicate artistic taste. Pickling and sandblasting technologies are in the past. Today, with the help of a laser machine, each person can create a highly detailed pattern

RPK-16 machine gun: specifications. Kalashnikov light machine gun

At the international presentation of weapons "Army-2016", held in September 2016, the RPK-16 machine gun, the brainchild of domestic gunsmiths, was demonstrated. It will be discussed in this article

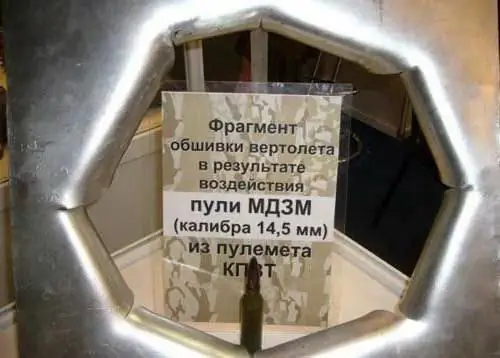

KPVT, machine gun. Heavy machine gun Vladimirov KPV

The idea of defeating aircraft and lightly armored vehicles led to the creation of heavy machine guns with a caliber of more than 12 mm. Such machine guns were already able to hit a lightly armored target, get a low-flying aircraft or helicopter, as well as shelters behind which there was infantry. According to the classification of small arms, the 14.5-mm KPVT machine gun is already adjacent to artillery weapons. And in design, heavy machine guns have much in common with automatic guns

Laser engraving on plastic: types of plastic, choice of pattern, necessary laser equipment and patterning technology

What types of plastic are used when applying laser engraving. Designs suitable for engraving and their types. How to edit and prepare photos for laser engraving. Necessary equipment for work, principles of its operation