2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

Fiber lasers are compact and rugged, point precisely and dissipate thermal energy easily. They come in many forms and, while having much in common with other types of optical quantum generators, have their own unique advantages.

Fiber lasers: how they work

Devices of this type are a variation of a standard solid-state source of coherent radiation with a working medium made of fiber rather than a rod, plate or disk. The light is generated by a dopant in the center of the fiber. The basic structure can range from simple to quite complex. The design of the ytterbium fiber laser is such that the fiber has a large surface to volume ratio, so heat can be dissipated relatively easily.

Fiber lasers are optically pumped, most often by diode quantum generators, but in some cases by the same sources. The optics used in these systems are typically fiber components, with most or all of them connected to each other. In some casesvolumetric optics are used, and sometimes an internal fiber optic system is combined with external volumetric optics.

The source of diode pumping can be a diode, a matrix, or a plurality of individual diodes, each of which is connected to a connector by a fiber optic light guide. The doped fiber has a cavity resonator mirror at each end - in practice, Bragg gratings are made in the fiber. There are no bulk optics at the ends, unless the output beam goes into something other than a fiber. The light guide can be twisted, so that if desired, the laser cavity can be several meters long.

Dual core structure

The structure of the fiber used in fiber lasers is important. The most common geometry is the dual core structure. The undoped outer core (sometimes called the inner cladding) collects the pumped light and directs it along the fiber. The stimulated emission generated in the fiber passes through the inner core, which is often single-mode. The inner core contains an ytterbium dopant stimulated by the pump light beam. There are many non-circular shapes of the outer core, including hexagonal, D-shaped and rectangular, which reduce the chance of the light beam not reaching the central core.

The fiber laser can be end- or side-pumped. In the first case, light from one or more sources enters the end of the fiber. In side pumping, light is fed into a splitter, which supplies it to the outer core. itdiffers from the rod laser, where the light enters perpendicular to the axis.

This solution requires a lot of design development. Considerable attention is paid to driving pump light into the core to produce a population inversion leading to stimulated emission in the inner core. The laser core can have a different degree of amplification depending on the doping of the fiber, as well as on its length. These factors are adjusted by the design engineer to obtain the required parameters.

Power limitations may occur, particularly when operating within single mode fiber. Such a core has a very small cross-sectional area, and as a result, light of very high intensity passes through it. At the same time, non-linear Brillouin scattering becomes more and more noticeable, which limits the output power to several thousand watts. If the output signal is high enough, the end of the fiber may be damaged.

Features of fiber lasers

Using fiber as the working medium gives a long interaction length that works well with diode pumping. This geometry results in high photon conversion efficiency as well as a rugged and compact design with no discrete optics to adjust or align.

The fiber laser, whose device allows it to adapt well, can be adapted both for welding thick sheets of metal and for producing femtosecond pulses. Fiber-optic amplifiers provide single-pass amplification and are used in telecommunications because they are able to amplify many wavelengths simultaneously. The same gain is used in power amplifiers with master oscillator. In some cases, the amplifier can work with a CW laser.

Another example is fiber-amplified spontaneous emission sources in which stimulated emission is suppressed. Another example is a Raman fiber laser with combined scattering amplification, which significantly shifts the wavelength. It has found application in scientific research, where fluoride glass fibers are used for Raman generation and amplification, rather than standard quartz fibers.

However, as a rule, the fibers are made of quartz glass with a rare earth dopant in the core. The main additives are ytterbium and erbium. Ytterbium has wavelengths from 1030 to 1080 nm and can radiate over a wider range. The use of 940 nm diode pumping significantly reduces the photon deficit. Ytterbium does not have any of the self-quenching effects that neodymium has at high densities, so neodymium is used in bulk lasers and ytterbium in fiber lasers (they both provide roughly the same wavelength).

Erbium emits in the range of 1530-1620 nm, which is safe for the eyes. The frequency can be doubled to generate light at 780 nm, which is not available for other types of fiber lasers. Finally, ytterbium can be added to erbium in such a way that the element will absorbpump radiation and transfer this energy to erbium. Thulium is another near-infrared dopant, which is thus an eye-safe material.

High efficiency

The fiber laser is a quasi-three-level system. The pump photon excites the transition from the ground state to the upper level. A laser transition is a transition from the lowest part of the upper level to one of the split ground states. This is very efficient: for example, ytterbium with a 940 nm pump photon emits a photon with a wavelength of 1030 nm and a quantum defect (energy loss) of only about 9%.

In contrast, neodymium pumped at 808nm loses about 24% of its energy. Thus, ytterbium inherently has a higher efficiency, although not all of it is achievable due to the loss of some photons. Yb can be pumped in a number of frequency bands, while erbium can be pumped at 1480 or 980 nm. Higher frequency is not as efficient in terms of photon defect, but useful even in this case because better sources are available at 980nm.

In general, the efficiency of a fiber laser is the result of a two-step process. First, this is the efficiency of the pump diode. Semiconductor sources of coherent radiation are very efficient, with 50% efficiency in converting an electrical signal into an optical one. The results of laboratory studies indicate that it is possible to achieve a value of 70% or more. With an exact match of the output radiation linefiber laser absorption and high pump efficiency.

Second is the optical-optical conversion efficiency. With a small photon defect, a high degree of excitation and extraction efficiency can be achieved with an opto-optical conversion efficiency of 60-70%. The resulting efficiency is in the range of 25-35%.

Various configurations

Fiber-optic quantum generators of continuous radiation can be single- or multi-mode (for transverse modes). Single-mode lasers produce a high-quality beam for materials operating or beaming through the atmosphere, while multi-mode industrial fiber lasers can generate high power. This is used for cutting and welding, and in particular for heat treatment where a large area is illuminated.

The long-pulse fiber laser is essentially a quasi-continuous device, typically producing millisecond-type pulses. Typically, its duty cycle is 10%. This results in a higher peak power than in continuous mode (typically ten times more) which is used for pulse drilling, for example. The frequency can reach 500 Hz, depending on the duration.

Q-switching in fiber lasers works the same way as in bulk lasers. Typical pulse duration is in the range of nanoseconds to microseconds. The longer the fiber, the longer it takes to Q-switch the output, resulting in a longer pulse.

Fiber properties impose some restrictions on Q-switching. The non-linearity of a fiber laser is more significant due to the small cross-sectional area of the core, so the peak power must be somewhat limited. Either volumetric Q switches can be used, which give better performance, or fiber modulators, which are connected to the ends of the active part.

Q-switched pulses can be amplified in the fiber or in a cavity resonator. An example of the latter can be found at the National Nuclear Test Simulation Facility (NIF, Livermore, CA), where an ytterbium fiber laser is the master oscillator for 192 beams. Small pulses in large doped glass slabs are amplified to megajoules.

In locked fiber lasers, the repetition rate depends on the length of the gain material, as in other mode locking schemes, and the pulse duration depends on the gain bandwidth. The shortest are in the 50 fs range and the most typical are in the 100 fs range.

There is an important difference between erbium and ytterbium fibers, as a result of which they operate in different dispersion modes. Erbium-doped fibers emit at 1550 nm in the anomalous dispersion region. This allows the production of solitons. Ytterbium fibers are in the region of positive or normal dispersion; as a result, they generate pulses with a pronounced linear modulation frequency. As a result, a Bragg grating may be needed to compress the pulse length.

There are several ways to modify fiber laser pulses, particularly for ultrafast picosecond studies. Photonic crystal fibers can be made with very small cores to produce strong non-linear effects, such as supercontinuum generation. In contrast, photonic crystals can also be made with very large single-mode cores to avoid non-linear effects at high powers.

Flexible large core photonic crystal fibers are designed for high power applications. One technique is to intentionally bend such a fiber to eliminate any unwanted higher order modes while retaining only the fundamental transverse mode. The non-linearity creates harmonics; by subtracting and adding frequencies, shorter and longer waves can be created. Nonlinear effects can also compress pulses, resulting in frequency combs.

As a supercontinuum source, very short pulses produce a wide continuous spectrum using self-phase modulation. For example, from the initial 6 ps pulses at 1050 nm produced by an ytterbium fiber laser, a spectrum is obtained from the ultraviolet to over 1600 nm. Another supercontinuum IR source is pumped with an erbium source at 1550 nm.

High power

The industry is currently the largest consumer of fiber lasers. Power is in high demand right now.about a kilowatt, used in the automotive industry. The automotive industry is moving towards high-strength steel vehicles to meet durability requirements and be relatively light for better fuel economy. It is very difficult for ordinary machine tools, for example, to punch holes in this kind of steel, but coherent radiation sources make it easy.

Metal cutting with a fiber laser, compared to other types of quantum generators, has a number of advantages. For example, near infrared wavelengths are well absorbed by metals. The beam can be delivered over the fiber, allowing the robot to easily move focus when cutting and drilling.

Fiber meets the highest power requirements. The US Navy weapon, tested in 2014, consists of 6-fiber 5.5-kW lasers combined into one beam and emitting through a forming optical system. The 33 kW unit was used to destroy an unmanned aerial vehicle. Although the beam is not single-mode, the system is interesting because it allows you to create a fiber laser with your own hands from standard, readily available components.

The highest power single-mode coherent light source from IPG Photonics is 10 kW. The master oscillator produces a kilowatt of optical power, which is fed into the amplifier stage pumped at 1018 nm with light from other fiber lasers. The whole system is the size of two refrigerators.

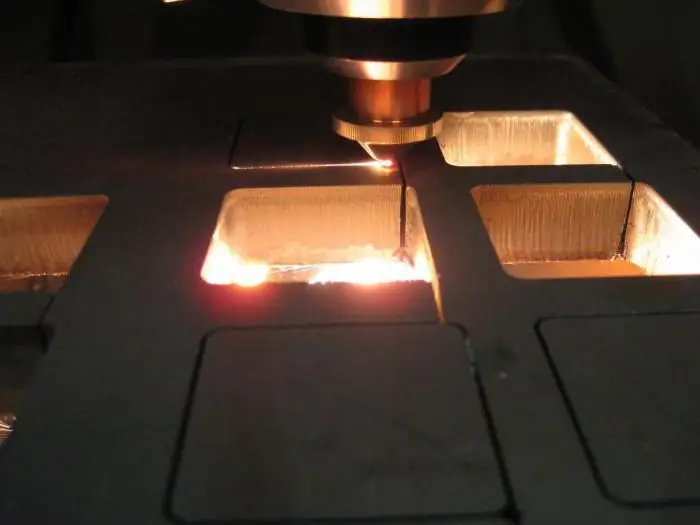

The use of fiber lasers has also spread to high-power cutting and welding. For example, they replacedresistance welding of sheet steel, solving the problem of material deformation. Controlling power and other parameters allows very precise cutting of curves, especially corners.

The most powerful multi-mode fiber laser - a metal cutting machine from the same manufacturer - reaches 100 kW. The system is based on a combination of an incoherent beam, so it is not an ultra-high quality beam. This durability makes fiber lasers attractive to industry.

Concrete drilling

4KW multi-mode fiber laser can be used for concrete cutting and drilling. Why is this needed? When engineers are trying to achieve earthquake resistance in existing buildings, one has to be very careful with concrete. If steel reinforcement is installed in it, for example, conventional hammer drilling can crack and weaken the concrete, but fiber lasers cut it without crushing it.

Quantum generators with Q-switched fiber are used, for example, for marking or in the production of semiconductor electronics. They are also used in rangefinders: hand-sized modules contain eye-safe fiber lasers with a power of 4 kW, a frequency of 50 kHz and a pulse width of 5-15 ns.

Surface treatment

There is a lot of interest in small fiber lasers for micro- and nanomachining. When removing the surface layer, if the pulse duration is shorter than 35 ps, there is no spattering of the material. This prevents the formation of depressions andother unwanted artifacts. Femtosecond pulses produce non-linear effects that are not sensitive to wavelength and do not heat up the surrounding space, allowing operation without significant damage or weakening of the surrounding areas. In addition, holes can be cut at high depth-to-width ratios, such as quickly (within milliseconds) making small holes in 1mm stainless steel using 800 fs pulses at 1 MHz.

Can also be used for surface treatment of transparent materials such as human eyes. To cut a flap in ocular microsurgery, femtosecond pulses are tightly focused by a high-aperture objective at a point below the ocular surface, without causing any damage to the surface, but destroying the ocular material at a controlled depth. The smooth surface of the cornea, which is essential for vision, remains intact. The flap, separated from below, can then be pulled up for surface excimer laser lens formation. Other medical applications include shallow penetration surgery in dermatology, and use in some types of optical coherence tomography.

Femtosecond lasers

Femtosecond quantum generators are used in science for excitation spectroscopy with laser breakdown, time-resolved fluorescence spectroscopy, as well as for general materials research. In addition, they are needed for the production of femtosecond frequencycombs needed in metrology and general research. One of the real applications in the short term will be atomic clocks for next-generation GPS satellites, which will improve positioning accuracy.

Single frequency fiber laser is produced with spectral linewidth less than 1 kHz. It is an impressively small device with output power ranging from 10mW to 1W. It finds application in the field of communications, metrology (for example, in fiber gyroscopes) and spectroscopy.

What's next?

As for other R&D applications, many more are being explored. For example, a military development that can be applied to other areas, which consists in combining fiber laser beams to obtain one high-quality beam using coherent or spectral combination. As a result, more power is achieved in the single-mode beam.

Production of fiber lasers is growing rapidly, especially for the needs of the automotive industry. Non-fiber devices are also being replaced with fiber ones. In addition to general improvements in cost and performance, femtosecond quantum generators and supercontinuum sources are becoming increasingly practical. Fiber lasers are becoming more niche and are becoming a source of improvement for other types of lasers.

Recommended:

Mobile gas station: description, device, principle of operation, application

Mobile gas station is quite a popular business idea these days. Therefore, the achievement of any success in this area can only be possible if you pay maximum attention to the various key points that are described in this article

Acetate fiber. Production of acetate fiber

At all times, the textile industry has been one of the most important sectors of the national economy in our country, as it gave the state a huge amount of much-needed fabric, which was constantly required not only for the production of clothing, but even used in the production of weapons

Solid-state laser: principle of operation, application

This article shows what are the sources of monochromatic radiation and what advantages a solid-state laser has over other types. Here it is described how the generation of coherent radiation occurs, why the pulsed device is more powerful, why engraving is needed. It also discusses the three mandatory elements of the laser and the principle of its operation

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities