2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:32

A turboprop engine is similar to a piston engine: both have a propeller. But in every other way they are different. Consider what this unit is, how it works, what are its pros and cons.

General characteristics

The turboprop engine belongs to the class of gas turbine engines, which were developed as universal energy converters and became widely used in aviation. They consist of a heat engine, where the expanded gases rotate the turbine and generate torque, and other units are attached to its shaft. The turboprop engine is supplied with a propeller.

It is a cross between piston and turbojet units. At first, piston engines were installed in aircraft, consisting of star-shaped cylinders with a shaft located inside. But due to the fact that they had too large dimensions and weight, as well as a low speed capability, they were no longer used, preferring the turbojet installations that appeared. But these engines were not without drawbacks. They coulddevelop supersonic speed, but consumed a lot of fuel. Therefore, their operation was too expensive for passenger transportation.

The turboprop engine had to cope with such a shortcoming. And this problem was solved. The design and principle of operation were taken from the mechanism of a turbojet engine, and propellers from a piston engine. Thus, it became possible to combine small dimensions, economy and high efficiency.

Engines were invented and built back in the thirties of the last century under the Soviet Union, and two decades later began their mass production. Power varied from 1880 to 11000 kW. For a long period they were used in military and civil aviation. However, they were not suitable for supersonic speed. Therefore, with the advent of such capacities in military aviation, they were abandoned. But civil aircraft are mainly supplied with them.

The device of a turboprop engine and the principle of its operation

The design of the motor is very simple. Includes:

- reducer;

- propeller;

- combustion chamber;

- compressor;

- nozzle.

The scheme of a turboprop engine is as follows: after being injected and compressed by a compressor, the air enters the combustion chamber. That's where the fuel is injected. The resulting mixture ignites and creates gases that, when expanded, enter the turbine and rotate it, and it, in turn, rotates the compressor and screw. Unspentenergy exits through the nozzle, creating jet thrust. Since its value is not significant (only ten percent), a turboprop engine is not considered a turbojet engine.

The principle of operation and design, however, are similar to it, but the energy here does not completely escape through the nozzle, creating jet thrust, but only partially, since the useful energy also rotates the propeller.

Working shaft

There are engines with one or two shafts. In the single-shaft version, the compressor, the turbine, and the propeller are located on the same shaft. In a two-shaft one, a turbine and a compressor are installed on one of them, and a propeller through a gearbox on the other. There are also two turbines connected to each other in a gas-dynamic way. One is for the propeller and the other is for the compressor. This option is the most common, since energy can be applied without starting the propellers. And this is especially convenient when the plane is on the ground.

Compressor

This part consists of two to six stages, allowing you to perceive significant changes in temperature and pressure, as well as reduce speed. Thanks to this design, it is possible to reduce weight and dimensions, which is very important for aircraft engines. The compressor includes impellers and a guide vane. The latter may or may not be regulated.

Propeller

This part generates thrust, but speed is limited. The best indicator is the level from 750 to 1500 rpm, since withincrease, the efficiency will begin to fall, and the propeller will turn into a brake instead of acceleration. The phenomenon is called the "locking effect". It is caused by the propeller blades, which, at high speeds, when rotating in excess of the speed of sound, begin to function incorrectly. The same effect will be observed by increasing their diameter.

Turbine

The turbine is capable of speeds up to twenty thousand revolutions per minute, but the screw will not be able to match it, so there is a reduction gear that reduces speed and increases torque. Reducers can be different, but their main task, regardless of type, is to reduce speed and increase torque.

It is this characteristic that limits the use of turboprops in military aircraft. However, developments to create a supersonic engine do not stop, although so far they have not been successful. To increase thrust, sometimes a turboprop engine is supplied with two propellers. At the same time, they implement the principle of operation due to rotation in opposite directions, but with the help of one gearbox.

As an example, we can consider the D-27 engine (turbopropfan), which has two screw fans attached to a free turbine by a gearbox. This is the only model of this design used in civil aviation. But its successful application is considered a big leap in improving the performance of the consideredmotor.

Advantages and disadvantages

Let's highlight the pluses and minuses that characterize the operation of a turboprop engine. The benefits are:

- light weight compared to piston units;

- economy compared to turbojet engines (thanks to the propeller, the efficiency reaches eighty-six percent).

However, despite such undeniable advantages, jet engines are in some cases the preferred option. The speed limit of a turboprop engine is seven hundred and fifty kilometers per hour. However, this is not enough for modern aviation. In addition, the noise generated is very high, exceeding the allowable values of the International Civil Aviation Organization.

Therefore, the production of turboprop engines in Russia is limited. They are mainly installed in aircraft that fly long distances and at low speeds. Then the application is justified.

However, in military aviation, where the main characteristics that aircraft should have are high maneuverability and quiet operation, and not efficiency, these engines do not meet the necessary requirements and turbojet units are used here.

At the same time, developments are underway to create supersonic propellers in order to overcome the "locking effect" and reach a new level. Perhaps, when the invention becomes a reality, jet engines will be abandoned in favor of turboprops and in the militaryairplanes. But at present, they can only be called "workhorses", not the most powerful, but stable functioning.

Recommended:

Classification of engines. Types of engines, their purpose, device and principle of operation

Nowadays, most vehicles are powered by an engine. The classification of this device is huge and includes a large number of different types of engines

General purpose engines: device, principle of operation, application, photo

Automotive equipment is mainly equipped with standardized internal combustion engines (ICEs), the design of which is focused on placement in the engine compartment. However, there is a great demand for power units of this kind in the garden equipment segments, from manufacturers of snowplows, snowmobiles, etc. Moreover, the requirements for integration and operational parameters in such cases differ sharply from automotive standards

Coke oven batteries: device, principle of operation, purpose. Coke production technology

Coke oven batteries are a complex and important industrial facility. We will talk about its work and device in the article

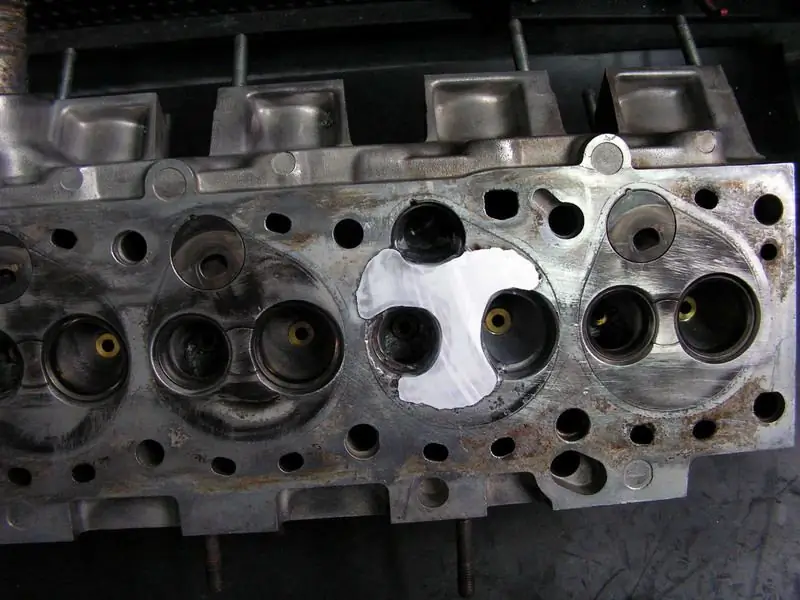

Repair of the engine block: step-by-step instructions with a description, device, principle of operation, tips from the masters

The block is the main part of almost any internal combustion engine. It is to the cylinder block (hereinafter referred to as the BC) that all other parts are attached, starting from the crankshaft and ending with the head. BCs are now made mainly of aluminum, and earlier, in older car models, they were cast iron. Cylinder block failures are by no means uncommon. Therefore, it will be interesting for novice car owners to learn how to repair this unit

Engine on alcohol: description, device, principle of operation, pros and cons, photo

Many people should be reproached with the inertia of the mind, which prevents them from seeing new possibilities and the application of ordinary things. For example, the engine on alcohol. Let not the best solution among all possible, but quite working. Moreover, there are a large number of embodiments. There is spirit gasoline. But not only him. Let's talk about everything in order