2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:32

GDS is a gas distribution station equipped with equipment that allows reducing the pressure of gas supplied from the main network to the required level. In addition, the tasks of the station include filtration and odorization, distribution and accounting of consumed gas.

Destination

The gas distribution station is the last facility in the chain of the gas transmission system and at the same time the main building for urban gas supply systems. In view of the fact that stopping the supply of gas to cities and large industrial enterprises is unacceptable, protective automation is provided in the GDS. Moreover, protective automation is made according to the principle of redundancy. The reserve line is switched on when the main reduction line fails.

GRS is for:

- receiving gas from main gas pipelines;

- cleaning it from various mechanical impurities;

- pressure reduction to the values required in urban systems;

- maintain pressure at a constant level;

- odorization and gas heating;

- determine its consumption.

Types of stations

GDS and AGDS are divided according to their purpose:

- Automatic on branches of the main gas pipelines - to provide gas to small settlements. Additionally subdivided into gas control stations (1000-30000 m3/h) and gas control units (up to 1500 m3/h).

- Control and distribution points - feed industrial and agricultural facilities, ring gas pipelines around large settlements and cities 2000-12000 m3/h).

- Field GDS - installed in gas fields, they clean the extracted raw materials from moisture and impurities.

- End stations - built directly at the consumer (enterprises, settlements).

Automation

In recent years, automated gas distribution stations have become widespread. AGRS with a capacity of up to 200000 m3/h operate without watch. In this case, the stations have a set of equipment and instrumentation that allow it to be operated in an automated mode.

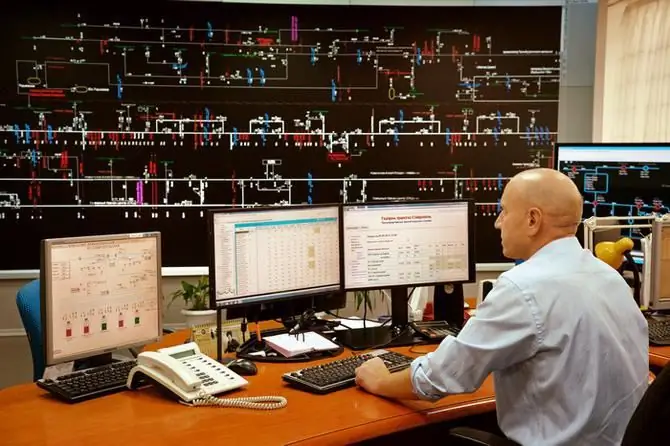

The maintenance of such GDS is carried out remotely. The operator of the gas distribution station, as a rule, is located in the premises of the service organization, monitoring can even be carried out at home. In the event of an emergency, sound and light signals are transmitted to the premises and residential houses of the operators, wholocated at a distance of no more than 0.5 km from the controlled station. Maintenance of GDS with a capacity of more than 200,000 m3/h is carried out on a watch basis.

Equipment

Gas distribution station includes a series of process equipment:

- disabling device at the entrance;

- filters;

- heater;

- gas pressure reduction and regulation line;

- device for measuring the flow of incoming gas;

- outlet disconnect device.

As pressure regulators at the station, regulators of direct action of the RD type and indirect action of the RDU type are used.

Technological cycle

The incoming gas is received by the gas distribution station. The scheme of its movement along the technological chain is as follows:

- From the main gas pipeline, gas first passes through a shut-off device and enters the filter.

- After that, it is pumped into the first stage of reduction, which has two or three lines, one of which is a reserve one. If there are two reduction lines, the reserve thread is calculated for one hundred percent productivity, and in the case of three lines - for 50%. The spare line can be used for bypassing the first stage with the above scheme.

- If the pressure at the GDS inlet is 4 MPa, then in the first stage the gas pressure is reduced to 1-1.2 MPa, and in the second stageup to 0.2-0.3 MPa. After the second stage, the gas pressure will have a value of 0.6-0.7 MPa.

Installation of filters and pressure control

The choice of filter location depends on the inlet pressure and gas composition. If the gas distribution station receives wet gas, then filters must be installed before the 1st reduction stage. Filters in this case will capture both condensate and mechanical impurities. After that, the mixture of dust with condensate enters the settling tanks. The settled product is sent to containers, from where it is periodically pumped out and transported in tankers.

If the operating pressure at the GDS inlet is less than 2 MPa, then the filters are installed after the 1st stage of reduction. With such a scheme for installing filters, bypassing (installation of a bypass line) of the first stage is performed. Filters in this case are adjusted to a pressure of 2.5 MPa. When the gas pressure at the inlet rises above 2.5 MPa, the shut-off device on the bypass line is closed and the gas is directed to the line of the 1st stage of reduction. After passing it, the gas is sent to the second stage, and after the 2nd - to the outlet gas pipeline.

If the gas distribution station requires the replacement of equipment on the main reduction line, as well as when creating an emergency, this line is turned off and the bypass line is opened, equipped with a shut-off device and a reducing valve. Adjustment of the gas flow and its pressure is carried out in this case manually.

Automated deviceGDS

Automated gas distribution stations have several equipment layout options. However, all of them must take into account the danger of both hydrate formation and external freezing of external reduction units. In this regard, in winter, the station staff has to pay special attention to the above factors. Gas heating units are used to prevent hydrate formation in GDS.

The heating unit includes a heater and a water boiler. Water enters the boiler from a special tank, the actual heating of water in the boiler is carried out by burning gas supplied to the GDS and passed through the reduction system. The gas burner device of the hot water boiler operates at low gas pressure. To prevent the supply of gas for combustion into the furnace of a hot water boiler with a pressure above the established limits, there is a safety device. Thus, the gas with inlet pressure entering the GDS is first sent to the filters for cleaning, and then to the heater. In the heater, the gas is heated, as a result of which hydrate formations are removed from it. After passing the heater, the dried gas enters the reduction lines and then into the outlet gas pipeline.

Safety measures

In order to avoid explosions and fires, special installations are installed at the GDS to give a smell to gas. These installations are installed when gas is not odorized at the headworks or its degree is below the established limits. Gas odorization plants are divided into bubbling, drip and wick. The latter are also called evaporative.

Gas distribution station automation

The principle of operation of an automated GDS with home service is as follows. When the outlet gas pressure deviates above the allowable value, the sensor, set to a certain value, gives the command to switch the valve with simultaneous notification of the station staff using sound and light alarms located on the shield.

In the event that the gas pressure at the outlet of the GDS rises by 5% above the set nominal pressure value, the corresponding sensor is triggered. As a result, the control valve on one of the working reduction lines will begin to close, thereby reducing the outlet gas pressure. If the pressure does not decrease, then another sensor will be triggered, which will give a command to cover the control valve even more, up to the complete shutdown of the entire reduction line. In the case of a decrease in outlet pressure to 0.95R, the reserve line opens.

Technical condition

Despite the simplicity of the device, gas distribution stations need to be updated. The construction of gas distribution stations in most cases was carried out in the 70s, when thousands of kilometers of gas pipelines were laid from Siberian fields to European consumers, and mass gasification of settlements and enterprises of the Soviet Union was carried out. Nearly 34% of HRSs reported30th anniversary, 37% - older than 10 years, only less than a third of the stations are equipped with modern equipment younger than 10 years old. At the moment, a comprehensive program of technical re-equipment and reconstruction of gas distribution stations is being considered.

Recommended:

Gazpromneft gas station: reviews, network description, fuel quality

Among all gas stations in Russia, Gazprom Neft gas stations stand apart, reviews of high fuel and quality service force an increasing number of car owners to use their services. According to opinion polls, about 40% of drivers prefer to refuel here, and their number is steadily growing every year

Gas production. Gas production methods. Gas production in Russia

Natural gas is formed by mixing various gases in the earth's crust. In most cases, the depth of occurrence ranges from several hundred meters to a couple of kilometers. It is worth noting that gas can form at high temperatures and pressures. In this case, there is no access of oxygen to the place. To date, gas production has been implemented in several ways, each of which we will consider in this article. But let's talk about everything in order

Container filling station. Container type car filling station

Container filling station is a fairly new type of gas stations. KAZS is quite easy to install. Since they are carried out in compliance with fire safety standards, they are easily approved. They can also be equipped as regular filling stations, only with a smaller volume of tanks, so they can be used not only by enterprises for their own needs, but also as commercial filling stations

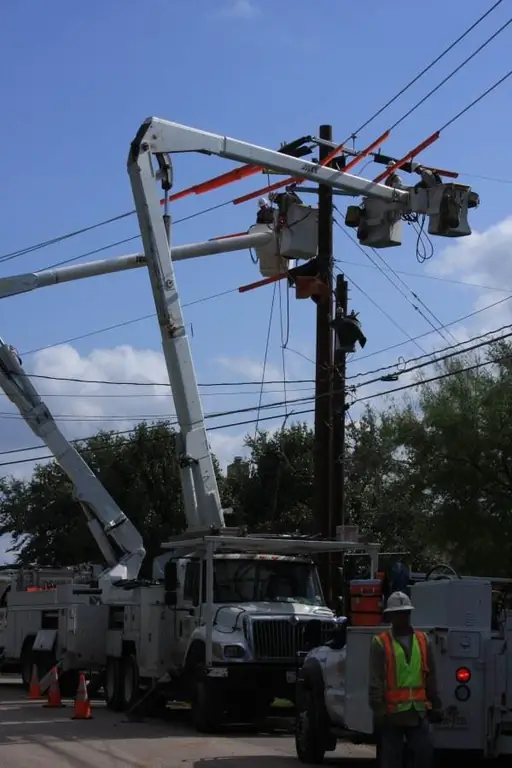

Electricity distribution: substations, necessary equipment, distribution conditions, application, accounting and control rules

Everyone knows that electrical energy is supplied to the place of its consumption from a direct source. However, such sources can be located at a great distance from the consumer. Because of this, the distribution of electricity and its delivery is a rather complicated process

Gas distribution point: device, operating requirements

Gas distribution points are designed to automatically lower the gas pressure and further maintain it at a given level, regardless of flow fluctuations within the nominal values