2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:33

Improving the quality of maintenance of buildings and industrial complexes has led to the widespread use of electricity sources and related infrastructure. In modern enterprises, the functions of energy supply systems involve the greatest responsibility, since the slightest failure in the power supply of equipment can lead to disruption of production processes. And this is only a part of the risks that need to be minimized at the stage of developing the project of the power supply system. No less significant are the issues of optimizing this infrastructure, since the cost of energy resources, as a rule, becomes the most expensive item in the estimate for the maintenance of enterprises.

Purpose of power supply systems

Usually, experts, along with the primary tasks of such systems, highlight their composition and characteristics. But the separation of these parameters will make it possible to more accurately determine the components and tasks of power supply systems. Their main purpose is to provide consumers with energy resources. Both a small private object and a large-scale enterprise can act as the latter.regional significance. By and large, the power supply system acts as a connecting component between the source and receivers of energy.

Structure and constituent elements

The power supply complex can be represented as a three-component system. This is directly the source of power, distribution infrastructure and means of supplying electricity. For the interconnection between these components, the device of the power supply system provides for a wide range of equipment and auxiliary elements:

- power lines (provide power transmission to receivers);

- step-down substations (carry out primary conversion of energy from its sources);

- distribution stations (perform an important function of network distribution of energy to supply several consumers);

- converter plants (prepare electrical flow for end use);

- overhead lines and cables (connecting elements that form a network in the power infrastructure);

- conductors (provide the final supply of energy to its receivers).

Varieties of generators

Power stations are more designed for autonomous power supply systems of various types. These are devices that include a motor that generates current. Modern power plants run on three main types of fuel - gasoline, gas and diesel.

Gasoline-fueled generators are commonly used asredundant systems and are calculated for short periods of operation. Such stations are cheaper and easier to maintain, but high fuel costs do not allow them to be used in intensive modes. A more powerful diesel power supply system benefits from low maintenance costs (20% less compared to gasoline counterparts), but the equipment itself and installation are more expensive. Gas power supply has found its place in servicing large industrial facilities - the advantages of such infrastructure include fuel affordability and durability.

Design

In the process of creating a model of a future power supply system, several stages are required, including the development of a power electrics plan, tracing, determining the location and parameters of equipment. Modern design of power supply systems includes the following works:

- create an equipment layout plan;

- drafting supply and distribution networks;

- selection of cables, design work on their parameters;

- creating cable reporting;

- wire routing;

- spec development;

- preparation of the layout of electrical wiring and related equipment.

When performing most of the design operations, specialists must determine the electrical loads and calculate the electrical network, which will serve to transmit and distribute electricity between its receivers. Also taken intoattention to demand factors and installed capacity.

Choice of equipment

When the project is ready, the specialists proceed to the selection of technical means that implement the power supply system. The basic data on the basis of which equipment is selected is provided by the design of power supply systems based on calculations and operating conditions. The components of the complex will determine its durability and reliability. To date, the list of equipment for such purposes includes cable and wiring products, high-voltage equipment, explosion-proof electrical engineering, lighting products, generators and power plants, transformer plants, power electronics and various components.

Installation

This is the final stage in the creation of a power supply complex, which includes the assembly and installation of equipment. Installation is carried out taking into account the project data and the characteristics of the enterprise - for example, in the case of the implementation of the task at production facilities, specialists take into account the possibility of a phased installation of individual components without the need to stop the workflow. At the same stage, automation of power supply systems is carried out at the expense of control panels and special controllers. Next, commissioning operations are carried out and the necessary amendments are made to the maintenance and operation regulations.

Principles of management and operation

When considering the operation of power supply systems, it is importanttake into account the fact that serving power sources and associated electrical equipment must produce as much resource as consumers require. In other words, the operation of power plants and networks is calculated for possible changes in receiver loads. Rational operation of power supply systems provides for special training of dispatch center personnel who will be able to accurately monitor the demand of receivers for electricity. Based on these indicators, the service selects the optimal number of generators when reducing loads or, on the contrary, launches backup stations when energy needs increase.

It is important to consider that the performance and safety of work processes in the enterprise depend on the quality of service by the power system. Disruptions in the power supply can cause accidents, downtime on conveyors and other unpleasant situations and phenomena, as a result of which the appearance of victims and the underproduction of manufactured products cannot be ruled out.

Criteria for the quality of power supply

Responsibility of systems that provide power to enterprises, necessitates maintaining sufficient indicators of their performance. In this regard, the maintenance of supply installations is based on the following principles:

- Ensuring the smooth operation of generators, networks and related power supply components. By the way, the reliability of power supply systems is one of the primary assessments of its quality, as well as maintainability with durability.

- Stability of the implementation of the plan forelectricity generation and its subsequent distribution, covering the required maximums for consumer loads.

- Preservation of the quality of energy supplied to receivers. It must meet the requirements of the supply electrical equipment in terms of frequency and voltage.

To achieve optimal working conditions, the power supply system is controlled by control panels. The latter, in turn, are provided with tools through which control, adjustment, control of power plants, power lines and step-down substations are carried out.

Operating modes

Any power supply complex provides for individual protective equipment in case of emergency. As a rule, these are relay protection systems, which led to the division of power system operation modes into three types: normal, emergency and post-accident. The first mode is characterized by uninterrupted power supply. Under such operating conditions, the power supply system of industrial enterprises supplies the resource in sufficient volume and the required quality. In emergency mode, the normal operation of the system is disrupted and lasts until the moment when the damaged component is also disabled. The post-accident operation of the power supply system continues until the normal operation of the entire complex is restored.

Classifications of power supply systems

There are several principles for the separation of power systems that supply consumers with electricity. Depending on thesource power supply system can be electrochemical, diesel-electric and nuclear. Such complexes are also different in configuration, for example, there are centralized, decentralized and combined. No less significant in the classification are the characteristics of current, direct and alternating.

Power supply systems are used in different conditions and at different facilities. In this regard, it is worth considering their mobility (stationary, wearable and transportable) and belonging to the consumer. But perhaps the main division relates to purpose. So, there are standby systems, backup and emergency. The standby power supply system of the enterprise performs its functions on a regular basis and, as a rule, is the main source of electricity. Backup systems, on the contrary, more often act as an auxiliary power supply infrastructure - to replace the main complex. Emergency power supply usually provides for the possibility of servicing the most critical facilities within a few hours or days.

Autonomous power supply systems

The concept of autonomous systems comes from the need to insure the power supply against possible failures in the backbone networks and other force majeure situations. Typically, autonomous power supply systems are used in enterprises with an established production process and the need for uninterrupted power supply. In essence, this is the supply of electricity with independent control. It is important to note that autonomous power supply is durable,but at the same time requires higher costs for installation and maintenance. On the other hand, this approach justifies itself in view of the reliability and stability of energy supply.

Recommended:

Hydraulic system: calculation, scheme, device. Types of hydraulic systems. Repair. Hydraulic and pneumatic systems

The hydraulic system is a special device that works on the principle of a liquid lever. Such units are used in the braking systems of cars, in loading and unloading, agricultural machinery and even in the aircraft industry

Recycled water supply - definition, scheme and features. Recycled water supply system

Recycling water supply is created for the purpose of ecological protection of the environment, economy, and also in case of emergency caused by the creation of a small enterprise. Profitability is determined by design calculations. In the future, it will only increase due to the increase in the cost of water and the growth of fines for environmental pollution

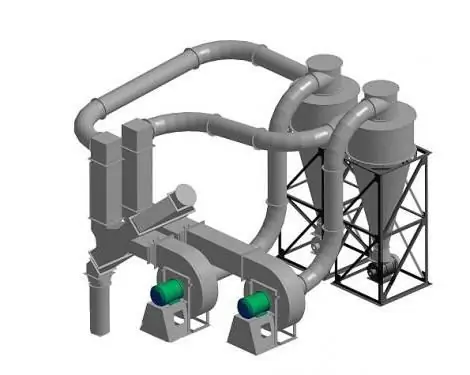

Aspiration systems: calculation, installation. Production of aspiration systems

Aspiration systems are systems that are designed to purify the air. The use of these installations is mandatory at all industrial enterprises that are characterized by harmful emissions into the atmosphere

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities