2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

Due to its unique properties and low cost, water is widely used in industry as a working fluid. Its processing after use (cleaning, cooling) makes it possible to create a circulating water supply with repeated use. Due to this, water consumption is significantly reduced, and environmental pollution is also prevented. As a result, comfortable living conditions are created for people.

Operation principle

The water supply system must be constantly replenished and periodically updated. Water is mainly used as a coolant or heat carrier. In each case, it is pre-cooled or heated. Water may be treated before reuse, as it becomes contaminated by products of technological processes.

The share of recycled water supply is increasing in all industries. The liquid is most often used in heat exchange equipment. Waterrepeatedly exposed to heating and cooling in spray pools or cooling towers. Most of it is lost in the evaporation process.

The circulating water supply of a chemical production enterprise is already 98%. There it is used in technological operations where water purification from industrial waste is required.

Separation of sludge from water makes it possible to process it and extract valuable components.

Water consumption

Water is used everywhere to cool mechanisms and machines in production processes. For processing 1 m3 of oil, it is required in 2.5 m3. For an oil refinery, the daily need for water is huge and discharge into the sewer is unacceptable here. Therefore, it passes through the treatment plant and is reused. Circulating water supply for CHP works on the principle of steam generation, its supply to turbines and condensation in cooling towers, after which the water is returned to work.

In everyday life, many of these technologies are not of interest. But owners of small businesses are constantly faced with the need to use recycled water in car washes, swimming pools, laundries, etc.

Water use patterns

There are 2 schemes for the operation of recycled water:

- no processing after use;

- with intermediate processing.

In the first case, water can be used after the technological process, when it retains acceptable performance. For example, drinking waterthey wash the container, after which it can be used for other household needs in the subsidiary farm, and the excess is discharged into the sewer. For industrial enterprises, such a scheme is usually unacceptable.

Enterprise water supply scheme

Recycle water must meet certain requirements:

- no negative impact on product quality;

- should not form s alt deposits in the system;

- low corrosive effect on equipment;

- no biofouling of the system.

Industrial water recycling system collects and accumulates most of the impurities in waste water receiving sumps and cooling tower tanks.

The tanks are cleaned periodically manually or by mechanizing the sludge removal process without stopping the system.

Water treatment

During evaporation, calcium s alts accumulate in the circulating water, which are deposited in pipes and on heat exchangers. They also precipitate as a result of heating water, when the solubility of gases decreases and bicarbonate ions decompose, forming an insoluble precipitate.

Carbonate deposits are prevented by acidification, phosphating, recarbonization and water softening. Acidification is a common method due to its low cost and ease of implementation. Here it is important to observe the dosage of acid to prevent corrosion of the equipment.

Recarbonization of water is produced by treatment with carbon dioxide. For thisash-free flue gases are used, which are mixed with water using ejectors or bubble pipes laid on the bottom of the tank.

Water phosphating requires a small consumption of reagents (1.5-2.5 g/m3), but the costs are still high. The advantage of the method is the absence of aggressive properties of the solution.

If there is enough oxygen and organic matter in the recycled water, the equipment may foul. This leads to a deterioration in heat transfer and an increase in hydraulic resistance in pipelines. Water chlorination and the addition of copper sulfate are used to combat fouling.

Which systems are best?

The use of recycling water supply systems is associated with significant costs for their creation and operation. At chemical enterprises, production products pollute the recycled water. A centralized system occupies large volumes, where a complete replacement or high-quality purge is sometimes impossible.

Efficient operation of circulating systems is achieved by combining closely spaced consumers with similar operating modes into groups with water coolers of small capacity. Local systems ensure the optimal operation of each consumer.

Car Wash Water System

Recycled water supply for car washes and other small businesses is being developed with the complete elimination of the possibility of wastewater discharge into the sewer. Water does not change its quality and can be used inclosed system.

Advantages of local treatment facilities:

- reducing water consumption by up to 90% with replenishment of water losses;

- no carry-over of pollution by sewage;

- sustainable.

All systems use settling and filtration as the main treatment methods. AROS and the like are common.

Effluent containing oil, dirt and fuel enters the sump and passes through 3 treatment sections with top and bottom overflow.

The sump is not included with the unit. The circulating water supply system contains it as a basis. It is designed and manufactured in accordance with the treatment plant manufacturer's recommendations. For a sink with one post, the volume of the sump is 6 m3.

The settled water is supplied by a submersible pump from the last section to the sand and gravel filter for cleaning from the remaining mechanical impurities and then to the storage tank. The unit can be equipped with a filter column with a sorbent to remove oil products.

The system has an automatic dosing pump supplying hydrogen peroxide solution or other sterilizing agent that kills germs and odors. UV lamps above the sump can also be used for this.

From the storage tank, water is supplied for reuse, passing through a fine cartridge filter. Liquid level intank is controlled automatically.

The Skat water recycling station works in a similar way. It is available in floor or underground versions. Layout options include deep wastewater treatment or without it. Structures retain mechanical impurities, oils, oil products and organic impurities.

Compact wastewater treatment plant equipment

Circulating water supply of industrial enterprises of small capacity includes the following equipment.

- The submersible pump is hung on a cable in the final section of the sump. Connection to the pipeline is carried out using adapters and a flexible hose. Management is made from a distributive case. Dry running float sensor included.

- The booster module includes a pump, pressure gauge and buffer tank. It allows you to maintain a constant pressure of water supplied to the sink.

- The filter column is a cylindrical container with media, vent valve and backwash switch.

- Purified water is collected in a storage tank. From above, it is provided with an input of a sterilizing reagent. The water level is controlled by sensors.

- The pumps are automatically controlled by an electronic system. There are indicators and switches on the front panel of the control cabinet, with the help of which the operator sets the operating modes of the system and controls its operation.

Revolving systems of industrialwater supply for washing automobile and railway transport can provide deep treatment of wastewater with their discharge into the sewer.

Conclusion

Recycling water supply is created for the purpose of ecological protection of the environment, economy, and also in case of emergency caused by the creation of a small enterprise. Profitability is determined by design calculations. In the future, it will only increase due to the increase in the cost of water and the growth of fines for environmental pollution.

Recommended:

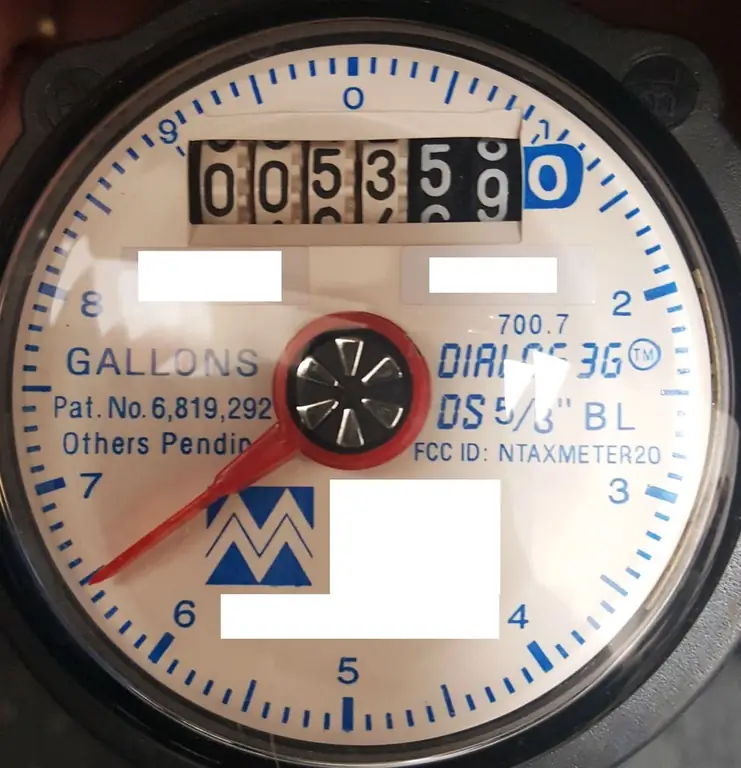

Shelf life of water meters: period of service and operation, verification periods, operating rules and time of use of hot and cold water meters

The shelf life of water meters varies. It depends on its quality, the condition of the pipes, the connection to cold or hot water, the manufacturer. On average, manufacturers claim about 8-10 years of operation of devices. In this case, the owner is obliged to carry out their verification within the time limits established by law. We will tell you more about this and some other points in the article

"Royal Water": customer and employee reviews, addresses, order conditions, delivery and water quality

Royal Water is one of the largest companies in the bottled water market. The company was founded in 1994. An extensive dealer network and a large number of branches determined the presence of the organization in many regions of the country

Logistics and supply chain management: description, functions and features

Work as a logistics manager is called by many the profession of the 21st century. What is it connected with? Who is a logistician and what functions does he perform? This will be discussed further

Power supply system: design, installation, operation. Autonomous power supply systems

Improving the quality of maintenance of buildings and industrial complexes has led to the widespread use of electricity sources and related infrastructure

The balance of water consumption and sanitation is a necessary calculation in the design of any facilities and in water use

One of the documents required by an economic entity when issuing a license for the use of a surface water body or when issuing a license for the extraction of groundwater is the balance of water consumption and water disposal. This water management calculation is also mandatory when designing any object of the national economy or a residential building