2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:35

Radiation control is based on the ability of the nuclei of certain substances (isotopes) to decay with the formation of ionizing radiation. In the process of nuclear decay, elementary particles are released, which is called radiation or ionizing radiation. The properties of radiation depend on the type of elementary particles emitted by the nucleus.

Corpuscular ionizing radiation

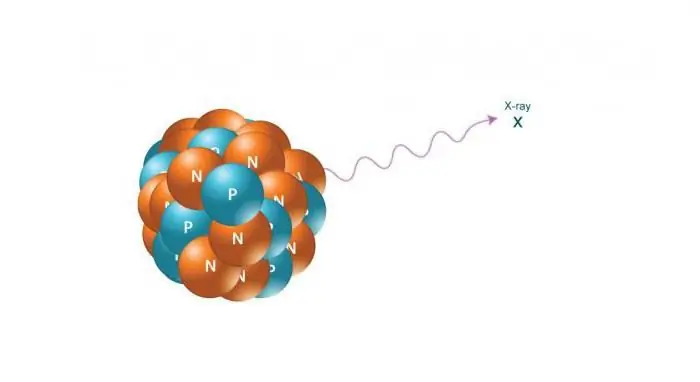

Alpha radiation appears after the decay of heavy helium nuclei. The emitted particles consist of a pair of protons and a pair of neutrons. They have a large mass and low speed. This is the reason for their main distinguishing properties: low penetrating power and powerful energy.

Neutron radiation consists of a stream of neutrons. These particles do not have their own electric charge. Only when neutrons interact with the nuclei of the irradiated substance, charged ions are formed, therefore, secondary induced radioactivity is formed in the irradiated object during neutron radiation.

Beta radiation occurs during reactions inside the nucleuselement. This is the transformation of a proton into a neutron or vice versa. In this case, electrons or their antiparticles, positrons, are emitted. These particles have a small mass and extremely high speed. Their ability to ionize matter is small compared to alpha particles.

Ionizing radiation of quantum nature

Gamma radiation accompanies the above processes of emission of alpha and beta particles during the decay of an isotope atom. There is an emission of a stream of photons, which is electromagnetic radiation. Like light, gamma radiation has a wave nature. Gamma particles move at the speed of light and therefore have a high penetrating power.

X-rays are also based on electromagnetic waves, so they are very similar to gamma rays.

Also called bremsstrahlung. Its penetrating power directly depends on the density of the irradiated material. Like a light beam, it leaves negative spots on the film. This X-ray feature is widely used in various fields of industry and medicine.

In the radiographic method of non-destructive testing, gamma and X-ray radiation, which are of an electromagnetic wave nature, as well as neutron, are mainly used. For the production of radiation, special devices and installations are used.

X-ray machines

X-rays are produced using x-ray tubes. This is a glass or ceramic-metal sealed cylinder from which air is pumped out foracceleration of the movement of electrons. Electrodes with opposite charges are connected to it on both sides.

The cathode is a spiral of tungsten filament that directs a thin beam of electrons to the anode. The latter is usually made of copper, has an oblique cut with an angle of inclination from 40 to 70 degrees. In the center of it there is a tungsten plate, the so-called anode focus. An alternating current with a frequency of 50 Hz is applied to the cathode to create a potential difference at the poles.

The flow of electrons in the form of a beam falls directly on the tungsten plate of the anode, from which the particles sharply slow down the movement and electromagnetic oscillations occur. Therefore, X-rays are also called braking rays. In radiographic control, X-rays are mainly used.

Gamma and neutron emitters

A source of gamma radiation is a radioactive element, most commonly an isotope of cob alt, iridium, or cesium. In the device, it is placed in a special glass capsule.

Neutron emitters are made according to a similar scheme, only they use the energy of a neutron flux.

Radiology

According to the method of detecting the results, radioscopic, radiometric and radiographic control are distinguished. The latter method differs in that the graphic results are recorded on a special film or plate. Radiographic control occurs by applying radiation to the thickness of the controlled object.

On the belowobject of control, an image appears on the detector, on which possible defects (shells, pores, cracks) appear as spots and stripes, consisting of voids filled with air, since the ionization of substances of different density during irradiation occurs inhomogeneously.

For detection, plates made of special materials, film, x-ray paper are used.

Advantages and disadvantages of radiographic weld inspection

When checking the quality of welding, magnetic, radiographic and ultrasonic testing is mainly used. In the oil and gas industry, pipe weld joints are especially carefully checked. It is in these industries that the radiographic method of control is the most in demand due to its undoubted advantages over other methods of control.

Firstly, it is considered the most visual: on the detector you can see an exact photocopy of the internal state of matter with the locations of defects and their outlines.

Another advantage is its unique accuracy. When conducting ultrasonic or fluxgate testing, there is always the possibility of false alarms of the detector due to the contact of the finder with the irregularities of the weld. With non-contact radiographic testing, this is excluded, i.e. surface roughness or inaccessibility is not a problem.

Third, the method allows you to control various materials, including non-magnetic.

And finally, the method is suitable for working in complexweather and technical conditions. Here, radiographic control of oil and gas pipelines remains the only possible one. Magnetic and ultrasonic equipment often malfunctions due to low temperatures or design features.

However, it also has a number of disadvantages:

- radiographic method of testing welded joints is based on the use of expensive equipment and consumables;

- trained personnel required;

- working with radioactive radiation is hazardous to he alth.

Preparation for control

Preparation. X-ray machines or gamma flaw detectors are used as emitters.

Before starting the radiographic inspection of welds, the surface is cleaned, visual inspection is carried out in order to identify defects visible to the eye, marking the test object into sections and marking them. The equipment is being tested.

Checking the sensitivity level. Sensitivity standards are laid out on the plots:

- wire - on the seam itself, perpendicular to it;

- groove - departing from the seam at least 0.5 cm, the direction of the grooves is perpendicular to the seam;

- lamellar - departing from the seam at least 0.5 cm or on the seam, the marking marks on the standard should not be visible in the picture.

Control

Technology and schemes for radiographic inspection of welds are developed based on the thickness, shape, design featurescontrolled products, in accordance with the NTD. The maximum allowable distance from the object of control to the radiographic film is 150 mm.

The angle between the direction of the beam and the normal to the film must be less than 45°.

The distance from the radiation source to the controlled surface is calculated according to the NTD for various types of welds and material thicknesses.

Evaluation of results. The quality of radiographic control directly depends on the detector used. When radiographic film is used, each batch must be checked for compliance with the required parameters before use. Reagents for image processing are also tested for suitability in accordance with the NTD. Film preparation for inspection and processing of finished images should be carried out in a special dark place. Finished images should be clear, without unnecessary spots, the emulsion layer should not be broken. Images of standards and markings should also be viewed well.

Special templates, magnifiers, rulers are used to evaluate the results of control, measure the size of detected defects.

According to the results of the control, a conclusion is made on the suitability, repair or rejection, which is drawn up in the journals of the established form according to the NTD.

Application of filmless detectors

Today, digital technologies are increasingly being introduced into industrial production, including the radiographic method of non-destructive testing. There are many original developments of domestic companies.

Digital data processing system uses reusable flexible plates made of phosphorus or acrylic during radiographic inspection. X-rays fall on the plate, after which it is scanned by a laser, and the image is converted to a monitor. When checking, the location of the plate is similar to film detectors.

This method has a number of undeniable advantages over film radiography:

- no need for a long process of film processing and equipment of a special room for this;

- no need to constantly buy film and reagents for it;

- exposure process takes little time;

- instant digital image acquisition;

- quick archiving and storage of data on electronic media;

- reusable plates;

- Irradiation energy under control can be halved, and the penetration depth increases.

That is, there is a saving of money, time and a decrease in the level of exposure, and hence the danger to the staff.

Safety during radiographic inspection

In order to minimize the negative impact of radioactive rays on the he alth of a worker, it is required to strictly observe safety measures when performing all stages of radiographic inspection of welded joints. Basic Safety Rules:

- all equipment must be in good working order, havethe necessary documentation, performers - the required level of training;

- People not connected with production are not allowed in the control area;

- when the emitter is operating, the installation operator must be on the side opposite to the direction of radiation by at least 20 m;

- the source of radiation must be equipped with a protective screen that prevents the scattering of rays in space;

- it is forbidden to be in the zone of possible exposure for longer than the maximum allowable time;

- the level of radiation in the area where people are located must be constantly monitored using dosimeters;

- The venue should be equipped with protective equipment against penetrating radiation, such as lead sheets.

Regulatory and technical documentation, GOSTs

Radiographic control of welded joints is carried out in accordance with GOST 3242-79. Basic documents for radiographic control - GOST 7512-82, RDI 38.18.020-95. The size of the marking marks must comply with GOST 15843-79. The type and power of radiation sources is selected depending on the thickness and density of the irradiated substance in accordance with GOST 20426-82.

Sensitivity class and standard type are regulated by GOST 23055-78 and GOST 7512-82. The process of processing radiographic images is carried out in accordance with GOST 8433-81.

When working with sources of radiation, one should be guided by the provisions of the Federal Law of the Russian Federation "On Radiation Safety of the Population", SP 2.6.1.2612-10 "Basic Sanitaryrules for ensuring radiation safety", SanPiN 2.6.1.2523-09.

Recommended:

Visual control of welds: the essence of the conduct and step-by-step procedure

Completely eliminate the risk of low-quality connections do not allow even automatic and robotic welding machines. Therefore, regardless of the applied technology for the production of welding operations, after its execution, a procedure for a comprehensive check of the quality of the welds is implemented. The visual inspection method is the initial stage in the overall process of welding troubleshooting

Dielectric boots: state standard, testing and safety

According to regulatory documents, all means of protection are divided into basic and additional. At the same time, the second group is in no way inferior to the first, it helps to avoid trouble, to become a lifesaver when working in electrical installations with more than 1,000 V. In the article, we will talk about dielectric bots: what is it, what standard controls the quality and when the protective equipment must be tested

Ultrasonic testing of welded joints, methods and technology of testing

Ultrasonic testing - advanced technology for the study of welding joints and seams. It will be discussed in this article

Color flaw detection of welds: features and description

The article is devoted to color flaw detection of welds. The features of the procedure, its description, technological stages, etc. are considered

Non-destructive testing of welded joints: equipment, GOST

The article is devoted to methods of non-destructive testing of welded joints. The methods of control allowed by GOST and the equipment used are described