2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:35

The introduction of coke ovens into operation began in the 50s of the last century. The useful volume of the first typical furnaces was 21.6 Nm³. Further in the article we will consider the device of the named equipment.

General information

If we consider the device of this furnace as a unit used in industry, then it consists of several parts:

- The main part is the chamber in which the process of coal coking takes place.

- Next are the heating walls, where the gas needed to heat the stove burns.

- Another of the main parts is the regenerator, which serves as a heat recovery unit for waste gases generated after the combustion of products.

Also, coke ovens can be assembled into batteries, and the batteries, in turn, can be assembled into blocks.

On the territory of the Russian Federation, batteries consisting of 61, 65 or 77 furnaces are most often operated. If you look at foreign industry, then there batteries can include up to 120 stoves.

Side feed ovens

In coke ovens with side feed, feed adjustmentgas and air for heating the unit is produced along the heating wall. The adjustment process is carried out by replacing the regulating bricks-registers, as well as burners. Their location is at the base of the heating ducts, which are characterized by constantly elevated temperatures, as well as the inevitable clogging that occurs in these ducts.

Such conditions greatly complicate the process of adjusting the supply of gas and air, and also do not allow the installation of control devices with the required accuracy.

However, these shortcomings have been eliminated in coke ovens with a bottom supply. With this design, the means that regulate these processes are taken out of the furnace masonry, which makes them easily accessible to the personnel involved in the maintenance of the furnace. It is much easier to change control devices in furnaces with the named design.

Stove construction

In order to start the process of making coke, you need to load the charge into the furnace. To carry out this procedure, the unit has a hole, which is located in the upper ceiling of the chamber. There is also an opening designed to remove volatile gases generated during the coking process. The latter, passing through the gas outlet, enter a special chamber for collecting gases, from which they are sent to the capture shop.

From both ends of the chamber is equipped with doors that are removed at the end of the coking process. Through the resulting holes, readythe coke is pushed out of the oven by the coke pusher.

It's also worth noting that coke ovens are completely hermetically sealed. This is necessary in order to exclude the possibility of atmospheric air being sucked into the furnace, which will also have to be heated if this happens. And this, in turn, will increase the cost of heating gases, which will negatively affect the final cost of the product.

Coke production technology

The production process of this material is carried out in several stages:

- The whole process begins with the loading of the mixture into the furnace chamber and the subsequent leveling of the material with a rod. In order to avoid smoke in the atmosphere when the chamber is opened at the time of loading the material inside the furnace, a vacuum is created by injecting steam or gas. In addition, you can use a special gas suction system from the chamber.

- Next, the charge coking process takes place. During this time, the material is subject to all the necessary influences that lead to its transformation into coke, as well as into PKG. Also at this stage, the productivity of the furnace is determined, which is determined by the time required to obtain finished coke from the moment the charge is loaded inside it.

- The unloading of finished products, that is, coke or, as it is also called, coke "pie" is carried out in a quenching car. To carry out this operation, an automatic coke pusher is used.

Batteries

Coke oven battery is a specialized metallurgical unit, the main purposewhich is the preparation of coke - fuel for blast-furnace iron production.

It is important to note that such batteries are used for quite a long period of time without stopping. Most often, the period of their work is at least 25 years. During all this time, a high temperature is maintained inside the furnace, and the masonry of the structure itself is abraded by products when it is released from the chamber.

For these reasons, the construction of coke batteries is carried out only from refractory materials. These materials must withstand:

- mechanical forces exerted by the machine during operation;

- expansion pressure during coking;

- resist the pressure of all structural elements resting on these refractory materials.

It is also important to note that such metallurgical equipment as batteries include from 45 to 69 coke ovens.

Classification

Like any other industrial equipment, these furnaces, which are part of metallurgical plants, have a number of parameters by which they are classified. These include:

- The location of the chambers in the oven, which can be either horizontal or vertical.

- Method of loading the charge into the furnace, as well as the subsequent procedure for issuing the finished product. There are two types of ovens - with top loading and subsequent bottom dispensing of material, as well as with top loading and subsequent dispensing through side openings.

- Also distinguish between twocoke production process, which can be continuous or batch.

- One of the parameters to classify is how a particular oven is heated. This procedure can be carried out both with the help of blast-furnace, mixed or coke oven gases at the same time, and with the help of only coke oven or only blast-furnace gases.

On the territory of the Russian Federation, furnaces of the PK-2K systems with lateral supply are most often put into operation at metallurgical plants.

Hydraulic mode of operation

The hydraulic mode of operation of coke ovens is a clear distribution of pressures in the heating system of the entire unit as a whole. Special studies, as well as a long period of operation of this mode of operation, have revealed parameters that characterize the correct mode of operation of the furnace:

- The gas pressure in the coking chamber during the entire period of operation must be higher than in other compartments.

- The gas pressure in the chamber where the coking process takes place is a variable.

- The gas pressure in the upflow heating system must be lower than elsewhere.

Kiln operation

The most important parameter in the operation of the furnace is its performance. This parameter is influenced by almost all other indicators of the unit. The period of coke production, i.e. productivity, most of all depends on such characteristics as the width of the chamber, the thickness of the walls, the temperature in the walls, the properties of refractory materials, as well as the qualitycharge.

It is worth noting that currently the maximum speed that can be achieved with a coke oven is 32 mm/h. It must be understood that this parameter is derived taking into account the maximum allowable temperature that can be developed and maintained in the chamber. Also, one of the most important parameters that must be observed for the operation of a coke oven is the temperature of the finished "pie". It should be between 1000°C and 1050°C.

Recommended:

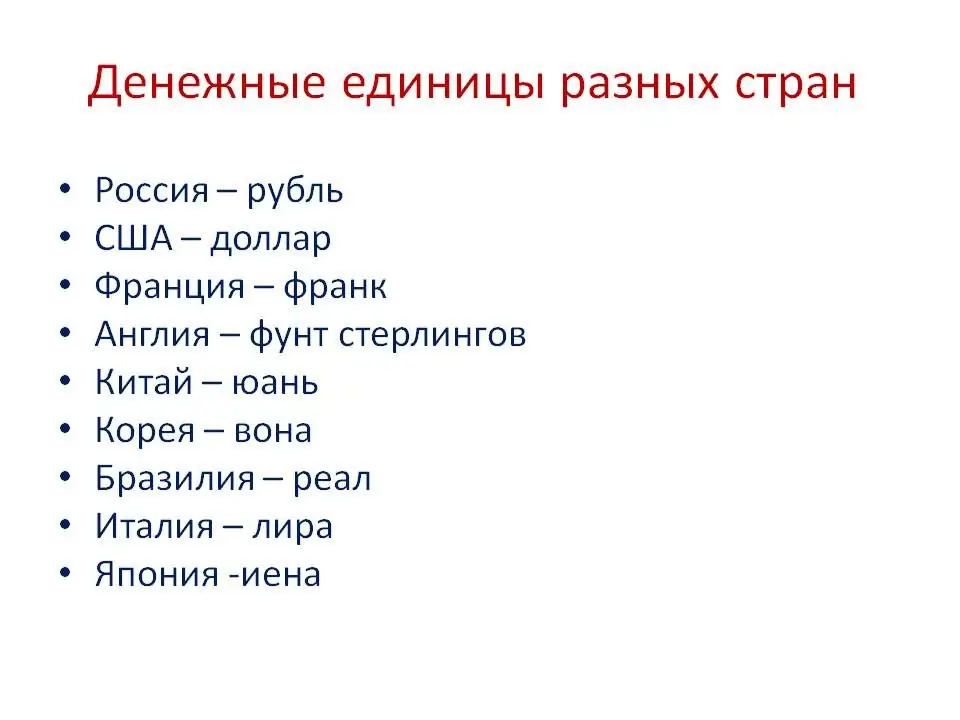

Monetary unit - what is it? Definition of the monetary unit and its types

The monetary unit serves as a measure for expressing the value of goods, services, labor. On the other hand, each monetary unit in different countries has its own measure of measurement. Historically, each state sets its own unit of money

Aircraft device for dummies. Aircraft device diagram

Few people know how an airplane works. Most don't care at all. The main thing is that it flies, and the principle of the device is of little interest. But there are people who cannot understand how such a huge iron machine rises into the air and rushes at great speed. Let's try to figure it out

Auxiliary power unit: specifications, purpose, device and resource indicators

An auxiliary power unit, or APU, is a unit that is very often used in aviation technology. By itself, this installation is necessary for obtaining mechanical energy. However, it cannot be used to move vehicles

A simple scheme for making money on the Internet. Programs for making money on the Internet

Earnings online are actively developing, and now it works much easier than 10 years ago. There are many opinions on this matter. If some are not sure about the truth of working on the Internet, then others believe that it provides great opportunities for generating income

Coke oven batteries: device, principle of operation, purpose. Coke production technology

Coke oven batteries are a complex and important industrial facility. We will talk about its work and device in the article