2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:36

The permanent connection of metal parts is the welding process in itself. At the same time, they try to heat the metal itself to a temperature that is optimal for a particular process. But there are also cold types of welding, when heating is not used, and the parts are compressed by mechanical force. As a result, the connection occurs.

Characteristics of the welding process

When different types of welding are used, metal processing occurs by applying concentrated or concentrated energy flows. Surfaces must be completely free from dirt and oxides. Only in this way it will be possible to hope for obtaining the corresponding result. Sedimentary pressure - this is the name of the pressure that occurs during welding. Thanks to him, a deformation is created at the junction, which allows you to connect the parts. It should be added that only very ductile metals provide the ability to use types of welding that do without heating.

Welding processes: about classification

There are two main ways in which metals can combine when heated. For example, when sediment pressure is used, it createsplastic deformation. In this case, an external force in the form of pressure is applied so that the metal is deformed at the junction. Such types of welding require the metal to maintain a solid state. In addition, in different situations, preheating of the surface may or may not be required. The main thing is that the mechanical properties of the metal do not change at all under such influence.

Melting as a method of welding

In this method, the parts are connected when the metal is melted. This procedure is carried out at the point of contact in the parts to be welded. Sometimes filler metal is used, sometimes such additives are dispensed with. This process is used, among other things, by some types of arc welding. The pouring of molten metal occurs arbitrarily. A common weld pool is formed. As the metal hardens, a hard weld is formed.

Basic types of welding

When multiple processes use the same heat source for heating or melting, welding is grouped into types. For example, there are types of fusion or pressure welding. Options of any kind are combined into methods. For example, electric welding methods can be seam, spot, and butt. The main species are grouped precisely on such grounds.

Additional information about classification

The types of energy used also sometimes become the basis for dividing welding processes into several groups. So, distinguish between electric and gaswelding. Conventionally, for example, laser and ultrasonic welding will refer specifically to the electric type. In this case, special devices are used that convert electrical energy, after which it becomes thermal. It is this type of it that allows you to heat the necessary parts to the required temperature.

Recommended:

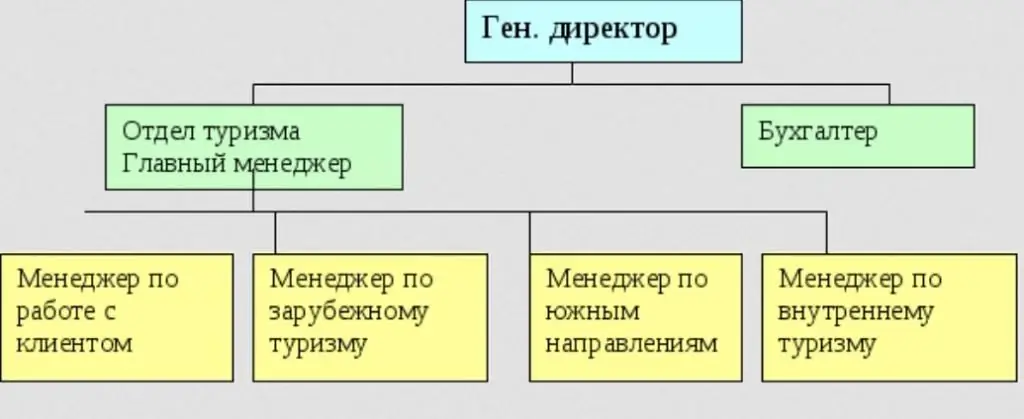

Types of tour operators and their characteristics. Functions and features of the activities of tour operators

The tour operator provides a wide range of travel services and simplifies the reservation of services in other cities and countries, taking on these tasks. In the field of tourism services, it occupies a special niche. In the article we will consider the types of activities of tour operators

Reserves of banks and their formation. Required bank reserves and their norm

Bank reserves ensure the availability of funds for the uninterrupted fulfillment of payment obligations regarding the return of deposits to depositors and settlements with other financial institutions. In other words, they act as a guarantee

Main types and types of business plans, their classification, structure and application in practice

Each business plan is unique, because it is developed for certain specific conditions. But you need to familiarize yourself with the features of various types of business plans in order to understand their key features. Experts recommend doing this before compiling your own similar document

Thermite welding: technology. The practice of thermite welding in everyday life and in the electrical industry

The article is devoted to thermite welding technology. The features of this method, the equipment used, the nuances of use, etc. are considered

Flux for welding: purpose, types of welding, flux composition, rules of use, GOST requirements, pros and cons of application

The quality of the weld is determined not only by the ability of the master to organize the arc correctly, but also by the special protection of the working area from external influences. The main enemy on the way to creating a strong and durable metal connection is the natural air environment. The weld is isolated from oxygen by a flux for welding, but this is not only its task