2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:36

The use of wood material in the arrangement of communication infrastructure justifies itself in many ways. One of the key factors in this choice for many users is the low price. Cheap poles are inexpensive in themselves and require virtually no maintenance investment during operation. This solution also facilitates the operation of power lines (TL) in severe weather conditions. Natural material resists both frost and heavy wind, and is also not subject to destruction under the influence of moisture. On the other hand, wooden power transmission poles have many disadvantages, which are mostly modest strength indicators. One way or another, there are many organizations involved in the maintenance of electrical networks that rely on this particular type of support.

Preparation of raw wood for supports

As a basis for poles supporting power lines, solid massifs of predominantly coniferous species are selected. As a rule, due to the high strength and resistance to external influences, pine or fir is selected for such needs. Sometimes used and larchlogs. Regardless of the selected species, each workpiece is subjected to a thorough examination for damage by fungi and insects. This is important for the subsequent maintenance of optimal technical and operational performance. Depending on the technology by which the wooden poles of the power transmission line will be manufactured, the primary processing of the base may include the operations of peeling and debarking. With the help of special machines, the logs are processed, during which the top layer is removed so that in the future it does not interfere with the penetration of the protective impregnation.

Technology for manufacturing supports

The main stage in the production of supporting logs still involves mechanical processing in order to form technological openings with holes. Horizontal ends are protected with special pastes already at the stage of basic refinement. If necessary, existing notches, spalls and notches are corrected - they can be eliminated provided that the depth is not more than 10% of the diameter of the workpiece. To maintain accuracy in the machining process, the production of wooden power transmission line poles at some enterprises provides for the use of special templates. According to them, for example, the parameters of notches and notches are checked.

Next, the drying phase begins, which prepares the wood for impregnation. According to the regulations, protective agents can be applied only if the moisture content of the array is not more than 28%. The debarked logs are dried in special thermal chambers, which differunusual design. The fact is that in such units hot air flows are not directed to the workpiece, but circulate around it. Thus, cracking and overheating of the material is not allowed.

Impregnation of supports

The use of special impregnations aims to protect wood from decay, destruction of the structure and, in general, loss of operational properties before external influences. In particular, protective compounds protect the wooden poles of power lines from fungal attack, insect attack and mold development. Such protection, for example, is provided by an antiseptic water-soluble preparation from the CCA family. This tool is characterized by increased efficiency and environmental safety, which made it one of the most common types of impregnation.

At the first stage, after application, a kind of vacuum is formed, which helps to remove excess moisture from the wood pores. In the future, the active components of the composition dissolve throughout the structure of the tree, strengthening it and forming a protective barrier.

Dimensions and weights

There are several categories of support poles that cause differences in standard sizes. So, the initial level is logs 9.5 m long, which have a diameter of 160 mm. The mass of such a workpiece is 200 kg. This is followed by supports of medium strength, which can reach a length of 11 m, their diameter is already 210 mm, and their weight is 300 kg. The most powerful structures in terms of the ability to endure physical activity can be built with a woodenpower line support, the weight of which reaches 400 kg. At the same time, the length remains the same as in the case of medium-strength poles - 11 m. But the diameter of such a support increases to 240 mm.

Operating life

Depending on the production technology, the average service life can vary from 10 to 20 years. This is precisely the middle corridor, since there are also logs whose working life does not exceed 5 years, as well as high-strength structures that retain their original properties even after 50 years. As a rule, the warranty period of wooden power transmission poles does not exceed 10 years. In practice, most often ordinary pillars of this type are used for 5-7 years. Such a short period is due to the lack of proper maintenance of the object or the fact that special impregnation was not used at all at the manufacturing stage. By the way, depending on the characteristics of protective equipment, the working life of the support can last for 4-6 years. Modern drugs are effective up to 15 years. However, a lot also depends on how correctly the compounding technique was performed.

Quality control

In the manufacturing process, the poles go through several stages of quality control. The first involves the examination of the element of the future power line for geometric accuracy. After that, the workpiece is sent for drying. Before impregnation, the material is checked for moisture content, which should not exceed 28%. Further, control verification activities are provided, during which the characteristics are determinedprotective agent used to treat wooden power transmission poles. Installation rules require that the material be delivered to the installation site with an optimally impregnated structure. To comply with this condition, technologists evaluate the depth of impregnation, and based on the results of the analysis, an appropriate quality certificate is formed.

Assembly of fittings

In the process of assembly activities, the pole is equipped with functional equipment that will be required when connected to the power line. The installation plan usually provides for the marking of hook locations, the creation of holes for hooks and the direct installation of fittings with insulators. Hook placement points are marked using a template, which can be made from a piece of aluminum rectangular bar. As a rule, the installation of wooden power transmission line poles using drilling is carried out on special machines in the factory. This ensures high accuracy of work and corresponding quality. However, during transportation, the assembled structure may be damaged, so the processing of the workpiece with assembly actions is sometimes carried out right at the installation site. In this case, a cordless power tool is used in the form of screwdrivers with a drill function.

Installation technique

Most often, the installation is carried out using drilling and crane machines. Only in some cases, when working with heavy or large structures, it is envisaged to use tractor cranes. At the installation site in the firsta pit is formed in which the pole will be installed. It must be carefully tamped, drained if necessary and covered with special insulators. Next, the direct installation of wooden power transmission line poles is carried out with the help of technology. The working bodies of a crane or a drilling and crane machine fix the prepared column, after which they move it into the pit. But this applies to lightweight supports, the height of which does not exceed 10 m. Heavy logs are installed in pits with concrete attachments - this is a kind of foundation in which the column is mechanically fixed.

Pole manufacturers

Products in the form of components and consumables for equipping power lines are widely represented in Russia. One of the largest representatives of this niche is the Kotelnich Mast Impregnation Plant. For more than 30 years this enterprise has been manufacturing high-quality wooden poles, and in recent years it has successfully switched to high-tech automated production of products. However, many manufacturers of wooden power transmission line poles in Russia are engaged in capacity upgrades, among which the OSMK and ProfTrade enterprises also stand out. If the first mentioned manufacturer focuses specifically on the production of poles, then in the assortment of these companies you can also find reinforcing components, insulating materials and auxiliary elements specifically for the characteristics of specific poles.

Reinforced concrete structures as an alternative

It should be noted right away that withfrom the point of view of operation, it is more profitable to use reinforced concrete structures. They are more reliable in all technical parameters, but, of course, they are much more expensive. In turn, the wooden poles of power transmission lines, even in the best designs, can only approach the characteristics of reinforced concrete structures with one or another success. This material, and subject to high-quality impregnation, will not be able to last as long as a concrete structure. However, the low lifespan is offset by the cost. Regular replacement of pillars at intervals of at least 5 years is well within the estimate for the use of reinforced concrete counterparts.

Conclusion

Wooden poles designed to organize power lines confirm the value of natural building material. Even modern fiberglass-based plastics are not able to replace such poles. Of course, this does not mean that wooden power transmission poles outperform composites in terms of strength and protection from external destructive influences. Moreover, the same fiberglass is ahead of concrete structures in a number of characteristics. But if you evaluate the materials in the totality of qualities, then wood is more practical. It is easier to process, manufacture, ship and install.

Recommended:

Power supply system: design, installation, operation. Autonomous power supply systems

Improving the quality of maintenance of buildings and industrial complexes has led to the widespread use of electricity sources and related infrastructure

Nuclear power plants. Nuclear power plants of Ukraine. Nuclear power plants in Russia

Modern energy needs of mankind are growing at a gigantic pace. Its consumption for lighting cities, for industrial and other needs of the national economy is increasing. Accordingly, more and more soot from burning coal and fuel oil is emitted into the atmosphere, and the greenhouse effect increases. In addition, there has been more and more talk in recent years about the introduction of electric vehicles, which will also contribute to the increase in electricity consumption

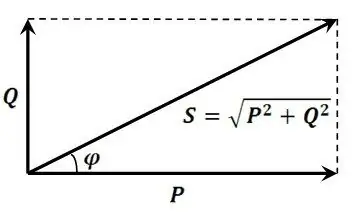

What is reactive power? Reactive power compensation. Reactive power calculation

In real production conditions, reactive power of an inductive nature prevails. The enterprises install not one electric meter, but two, one of which is active. And for the overexpenditure of energy “chased” in vain through power lines, the relevant authorities are mercilessly fined

Garage production: ideas from China. Production in the garage of dry building mixes, blinds, wooden toys, Chinese lanterns, toothpicks

What kind of production can you set up in your garage? What business ideas from China can be implemented there? What do you need to start a business in your garage?

Production of wooden windows: production technology

It is impossible to imagine a living space without a window, which is a conductor between the inner and outer space. Windows are made from different materials. But how wooden windows are made, and what types of them exist, read the article