2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:36

Kolomensky Heavy Machine Tool Plant (Kolomna) is Russia's leading manufacturer of presses and machine tools for various purposes. Included in the structure of the production center "Stankotekh".

Historical background

Kolomensky Heavy Machine Tool Plant celebrated its centennial anniversary. As early as 1914, agricultural workshops were built on this site. A year later, they were bought out by the Kolomna Machine-Building Plant, and instead of seeders and winnowers, the production of shells began.

After the revolution, Plant No. 4 retained its specialization. Before the Great Patriotic War, the production of artillery and anti-aircraft guns was mastered. By the end of 1941, the main facilities of the enterprise were evacuated to Krasnoyarsk, and repair of equipment and assembly of vehicles received under Lend-Lease were organized in empty workshops.

In 1948, on the basis of a defense enterprise, it was decided to create a powerful machine-tool plant, the products of which were so needed by the post-war country. The first machines were manufactured already in May 1948. For several decades, KZTS has become one of the largestmetalworking equipment manufacturers in the world.

Today

JSC Kolomna Heavy Machine Tool Plant has accumulated rich experience over 100 years. Its production facilities allow us to deliver effective technological solutions based on unique and high-tech machine-and-press equipment.

Main Specialization:

- Production of presses and various types of metalworking machines.

- Overhaul and modernization of machine tools.

- Production of tooling, accessories.

- Maintenance and repair, including post-warranty.

- Supply of imported machine tools.

In addition to the production of equipment, the Kolomna Plant carries out:

- Machining parts according to customer drawings.

- Comprehensive preparation of new industries, scientific developments and innovative projects.

- Development of control programs for CNC, implementation of specialized software systems.

Production structure

Kolomensky Zavod is part of ZAO Stankotekh. Its structure includes:

- Management, with marketing and accounting department.

- Electrical and commissioning department, including the laboratory of complete control systems and the sector for the development of specialized software.

- Department of the chief designer, which includes two main areas: the development and design of new unique equipment, including metalworking andpressing equipment, as well as the development of projects for the modernization and repair of existing metalworking, pressing equipment.

- Department of the chief technologist, which additionally includes a technical control section, a tool preparation section and a normalization section.

- The main production, which includes machine assembly shops, machining shops, blank-machining shop and forging shop.

- Electrical equipment manufacturing includes an assembly shop and a design office.

- Auxiliary production includes all auxiliary services for servicing the main production, including services responsible for the life support of buildings, crane facilities, a boiler house and other structures.

Production

Kolomensky Zavod produces large-sized heavy machine tools and presses. The release of new models, overhaul and modernization are carried out at production facilities in the city of Kolomna. At the moment, the total area of workshops and management structures is more than 85,000 m22.

The capabilities of the production base allow us to design and deliver on a turnkey basis machine tools, presses and automated complexes of any degree of complexity weighing up to 850 tons in the shortest possible time. The total number of employees of the production center, including auxiliary production, exceeds 400 people, which allows you to quickly and quickly complete a large number oforders for clients from different regions of Russia. The size of the workshops allows for the simultaneous manufacture and repair of up to 40 units of forging and pressing and metal-cutting equipment.

Standards and quality

Kolomensky Zavod successfully combines time-tested technologies for the production of unique machine tools and the most modern technologies of domestic and world machine tool building. In 2011, the production center was certified according to GOST RISO 9001-2008 quality standards.

Management maintains the closest contact with customers. If necessary, partners can conduct a full technical expertise of production. As part of the developed solution, the most suitable technologies are developed for specific projects:

- Perform the selection of equipment.

- Make their own machines or supply imported equipment.

- Develop and implement industrial software.

- Training of workers and maintenance personnel.

Assortment

Kolomensky plant manufactures and supplies the following machines:

- Milling machines (KU-695, SK6P, OCP).

- Gear hobbing (5A-CNC, 5B-CNC).

- Carousel (1M-CNC, 1H-CNC, VBL).

- Turning (KBT-400).

- Winding (OLTC, KU4-N).

- Hardening (KU-198-F1, KU-199-F1).

- Thread rolling (RP-K).

- For pipe processing (KTF, KTO, KSTK-530).

- For processing long products (KPT-360).

- Formetal forming (URS, SRV).

- Press equipment for various purposes (P5, P8-E, P9).

- Machines for special purposes.

Equipment produced at KZTS is distinguished by a high level of automation, the presence of complex and precise working mechanisms, CNC systems from leading manufacturers NCT, SIEMENS and others, which provides wide technological capabilities for the long term.

Kolomensky Heavy Machine Tool Plant: address

Production facilities are located in the southern part of the city, on the banks of the Oka River. Company address: Moscow region, city of Kolomna, prosp. Oksky-70. Index 140402.

CEO: Vladimir Viktorovich Pirogov.

Contact phone: (496)61-35-200.

Fax: (496)61-32-103.

Recommended:

Large-caliber machine guns of Russia and the world. Comparison of heavy machine guns

Even in the First World War, a fundamentally new and terrible weapon appeared on the battlefield. Large-caliber machine guns. In those years, there was no armor that could protect against them, and the shelters that were traditionally used by the infantry (made of earth and wood) generally made their way through with heavy bullets

NSVT heavy machine gun: overview, characteristics and description

Machine guns at the time of their appearance were not accidentally classified as artillery: the power of such weapons still amazes. Moreover, heavy "machine gunners" allow even mounted shooting, so that they can be attributed to artillery systems, albeit with tension, even today

RPK-16 machine gun: specifications. Kalashnikov light machine gun

At the international presentation of weapons "Army-2016", held in September 2016, the RPK-16 machine gun, the brainchild of domestic gunsmiths, was demonstrated. It will be discussed in this article

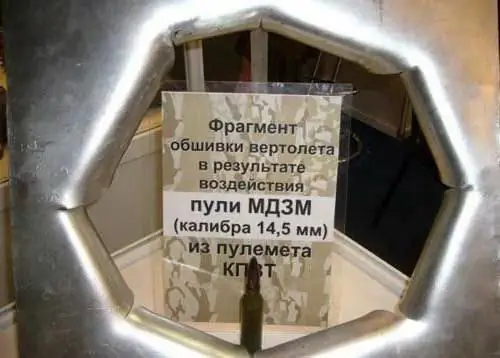

KPVT, machine gun. Heavy machine gun Vladimirov KPV

The idea of defeating aircraft and lightly armored vehicles led to the creation of heavy machine guns with a caliber of more than 12 mm. Such machine guns were already able to hit a lightly armored target, get a low-flying aircraft or helicopter, as well as shelters behind which there was infantry. According to the classification of small arms, the 14.5-mm KPVT machine gun is already adjacent to artillery weapons. And in design, heavy machine guns have much in common with automatic guns

Irkutsk heavy engineering plant: history and date of establishment, address, management, technical focus, stages of development, introduction of modern technologies and quality

Irkutsk heavy engineering plant is a city-forming enterprise producing equipment for leading industries in Russia. The company's products are supplied to the domestic market, finds recognition and demand abroad