2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Diesel cars on our roads are by no means uncommon. In the countries of Western Europe, they are in the majority. Diesel engines have a number of advantages over gasoline engines. But at the same time, there are some drawbacks. What is this motor, what is the diesel device and the principle of operation? Consider in our today's article.

Shared device

This engine has the same structure as the gasoline engine. So, here is:

- Cylinder block.

- Head.

- Crank mechanism.

The main difference between diesel and gasoline is the fuel system. If at the latter the fuel supply is carried out thanks to a mechanical or submersible pump, then a high-pressure fuel pump is used in the diesel engine. There are also injectors, but no spark plugs.

It should also be said that the load on the working elements of a diesel engine is higher. Therefore, all its components are reinforced.

Please note that modern diesel engines mayequipped with glow plugs. Some confuse them with spark plugs, but they are completely different things. In diesel vehicles, they are used to heat cold air in the cylinders. So, it is easier to start the internal combustion engine in winter.

The injection system itself on modern diesel engines is direct. On older engines, ignition took place in a special pre-chamber. The latter is a small cavity above the main combustion chamber with several holes through which oxygen enters.

Features

Among the features of this power unit, it is worth noting the degree of compression. They are twice as high as that of a gasoline engine. In view of this, the diesel engine has a special piston design. Their bottom is determined by the type of combustion chamber. The piston crown itself is higher relative to the upper plane of the cylinder block at TDC.

One more thing is the ignition method. As we said earlier, there are no usual candles here. But how does fuel ignite? The working mixture is ignited by the high temperature in the chamber, which is reached after the air is compressed by the piston.

The principle of operation of the diesel injection pump

The high-pressure pump receives fuel, which is pumped by the low-pressure priming pump from the tank. In a certain sequence, the injection pump pumps a portion of fuel into the injector line for each cylinder. These nozzles can only open when exposed to high pressure in the line. When it drops, the nozzles close.

How does the diesel engine itself work?

Consider the principle of dieselengine. Its essence of work lies in the compression ignition of the fuel in the chamber when mixed with heated air.

The mixture itself is supplied separately. So, first air is forced into the cylinder. Further, the piston begins to move up and in the TDC position, fuel is injected through the nozzle. In the process of compression, the air is heated to high temperatures (about 800 degrees Celsius). And the fuel is supplied under a pressure of 30 MPa.

Next, the mixture ignites spontaneously. This causes the piston to move down. So, a working stroke is made - energy is transferred to the crankshaft, as well as the flywheel. After the working stroke, the combustion products exit through the exhaust ports with the help of a purge. The gases then enter the atmosphere through the muffler. But on modern engines, gases can be recirculated. We will consider the principle of operation of the EGR on a diesel engine a little later.

Thus, the work cycle includes four cycles. These are intake, compression, stroke and exhaust. This is exactly the principle of operation of a four-stroke diesel engine. It must be said that fuel consumption depends on the correctness of its action. So, in the normal state, a lean mixture is used, which can significantly save on consumption.

Varieties of pumps

There are two types of injection pump:

- Inline.

- Distribution.

The first type includes separate sections. There are as many of them ascylinders on the engine. Each section has a sleeve with an incoming plunger. The latter operates due to the camshaft, which rotates from the engine crankshaft. Sections are arranged in a row. But now this type of injection pump is not used by manufacturers, since such a fuel system does not meet the requirements for noise and environmental friendliness.

Now about distributive. Such pumps produce much more pressure and meet all modern requirements. The required pressure is maintained depending on the current mode of operation of the internal combustion engine. In the design of such a pump there is one plunger-distributor. It performs translational movements to supply fuel and rotational movements to distribute it to the injectors of each of the cylinders.

Among the advantages of such pumps, it is worth highlighting small overall dimensions, low noise level, as well as stable operation at high engine speeds. At the same time, such a diesel engine is picky about the quality of fuel. All parts in the pump are lubricated with fuel, and the gaps are critically small. The slightest contamination provokes unstable engine operation and may lead to repair of fuel equipment.

About the Common Rail system

More than a decade ago, automakers began producing cars with the Common Rail system. What it is? This is high pressure direct injection. This system provides an increase in torque and power, as well as good fuel efficiency.

Let's consider the principle of the systemcommon rail diesel injection. The principle is based on the supply of fuel to the nozzles from the ramp. The pressure in it is maintained regardless of the speed of the crankshaft. Fuel injection is carried out by injectors at the command of the EDC controller. Special magnetic solenoids are built into it. The controller operates due to control signals from the electronic control unit.

Among the features of the injection system, it is worth noting the battery unit. It includes:

- Injectors.

- Distribution pipeline.

- Fuel line.

So, the control unit transmits a signal to the solenoids according to a given algorithm. And then the nozzle injects fuel into the chamber. Such a scheme makes it possible to achieve high accuracy in controlling the combustion process. As for the pressure, it can reach up to 2.5 atmospheres, which is very serious. So, the fuel burns with maximum efficiency. This allows you to increase the torque of the engine. And thanks to the exact dosage, fuel consumption is reduced and the toxicity of gases is reduced.

Recirculation system

This system is used on all diesel vehicles that meet Euro 4 requirements. It is also called the EGR. So, this system removes a certain amount of exhaust gases from the manifold in front of the turbine and transfers them to the channel in front of the intake manifold.

The system is a special valve and several nozzles for venting gases. The first one performs exhaust bypass and is electrically driven. On some engines, the EGR valve haspneumatic actuator.

Consider the principle of operation of the USR valve on a diesel engine. It is based on vacuum, which is produced by a special vacuum pump. The vacuum level is regulated by a special solenoid valve.

The working principle of the diesel recirculation system is simple. So, the electronic control unit receives data from sensors and evaluates the situation about the operation of the internal combustion engine in all modes. Next, the valve is opened or closed to supply exhaust gases to the manifold. This leads to a decrease in the oxygen concentration and a decrease in the combustion rate of the mixture in the chamber. As a result, the combustion temperature decreases and the formation of harmful oxides decreases. So, the system allows to reduce the toxicity of gases even when the internal combustion engine is running on a lean mixture.

Pros of diesel

Let's consider the advantages of these engines. The first and most important advantage is economy. Since a diesel engine has a slightly different operating principle (it operates on a lean mixture), an internal combustion engine can consume one and a half times less fuel than gasoline, with the same volume.

At the same time, the motor produces a good torque, which is important during acceleration. Another plus is that the torque shelf is quite wide. Traction is available literally from idle. Petrol ones sometimes have to spin up to five thousand.

Disadvantages of diesel

Since the principle of operation of a diesel engine is based on the self-ignition of the mixture, such engines are difficult to start in cold weather. Yes,For this they came up with special glow plugs. But then again, not all engines have them, and sometimes there are problems with them.

One of the biggest downsides is the cost of maintenance. The most expensive part is the fuel equipment. If it becomes unusable, it is worth preparing for a serious investment. It is very difficult to repair injectors or a fuel pump on your own. This requires skills and specialized equipment.

Among other disadvantages, it is worth noting the increased noise. No matter how technologically advanced a diesel engine is, it will still work louder than gasoline. This is one of the main reasons why car manufacturers have not switched to diesel engines for so long.

Another drawback is the high requirements for fuel and consumables. If we talk about modern diesel engines, in which the high-pressure fuel pump is lubricated by the fuel itself, its quality should be at the level. The same goes for oils. It is recommended to fill only synthetics, and change every 10 thousand kilometers.

Summing up

So, we found out which diesel engine has the principle of operation and what are its features. As you can see, with its advantages, this motor is not without a number of disadvantages. But is it worth buying a diesel car instead of a gasoline one? As practice shows, the purchase is justified, given that many expenses are offset by meager fuel consumption.

Recommended:

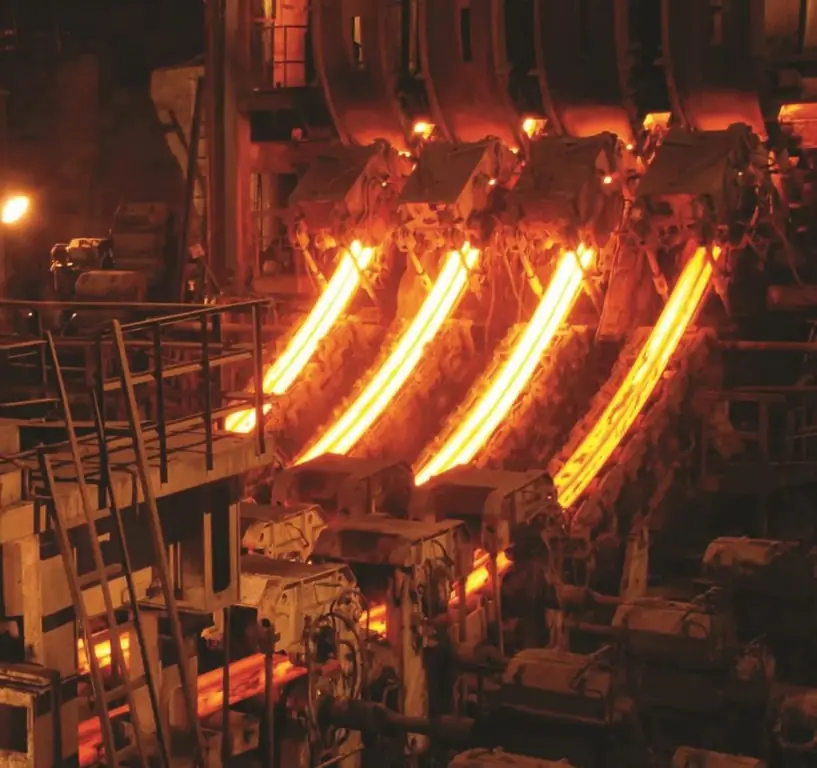

Continuous casting of steel: principle of operation, necessary equipment, advantages and disadvantages of the method

Today, a huge number of various things, parts, etc. are made of steel. Naturally, this requires a large amount of source material. Therefore, the plants have long been using the method of continuous casting of steel, characterized by the most important feature - high productivity

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities

Diesel submarines: history of creation, boat projects, principle of operation, advantages, disadvantages and stages of development

The idea of creating a submersible moving under water, actually a prototype of a submarine (hereinafter referred to as a submarine), arose long before their actual appearance in the 18th century. There are no exact descriptions of underwater vehicles in numerous legends, nor in the Renaissance genius Leonardo da Vinci