2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

LDPE is made from purified ethylene, and triethylaluminum and titanium tetrachloride act as an organometallic catalyst.

To obtain polyethylene in the domestic industry, several technological options are used, which differ in the type of structures, reactor capacity, methods of washing polyethylene from the catalyst used.

Technology

Most often, three consecutive operations are carried out: ethylene polymerization, the process of cleaning it from the catalyst and final drying. After mixing solutions of triethylaluminum and titanium tetrachloride, cyclohexal and gasoline are added to them. Heated to 50 C, a two percent solution is fed into the reactor, where ethylene is added via the airlift system. Stirring the mass contributes to the partial polymerization of ethylene into polyethylene.

To remove the catalyst from the polymer, the resulting decomposition products are filtered off and dissolved. Polyethylene is washed from the catalyst in a centrifuge using methyl alcohol.

Low-density polyethylene is pressed after washing, and substances are added to it to improve its quality. A stabilizer, ethylene glycol and sodium nitrophosphate are used to lighten it, and wax is used to make it more shiny.

Finally, polyethylene is dried and granulated. LDPE is available in granular and powder form.

LDPE pipes

Used for installation of gas, sewer and water systems.

Pipes are manufactured using continuous extrusion techniques. The raw material for production is polyethylene in granules.

Economically developed countries use such pipes in almost all systems.

HDPE pipes do not adversely affect water quality, as rust does not form on the inner walls and mineral s alts do not collect.

LDPE has found use in sewer systems as it is resistant to aggressive substances and high temperatures.

Gas pipes also do not collapse and do not lose their operational properties for a long time.

Durability is the main quality of HDPE pipes. They are shock-resistant, do not rot and do not rust, do not crack under the influence of high and low temperatures. Their service life is several decades.

High density polyethylene is relatively soft and elastic. Its material has an arrangement of moleculesrelatively rarefied, which primarily affects its density. A wide range of films are produced from LDPE. They are of very high quality, and for packaging material the best option, perhaps, cannot be found. It retains and withstands a set of positive properties even at temperatures reaching sixty degrees. The qualitative characteristics of such polyethylene do not change under the influence of chemicals. It is able to reliably isolate products from moisture and water vapor.

Recommended:

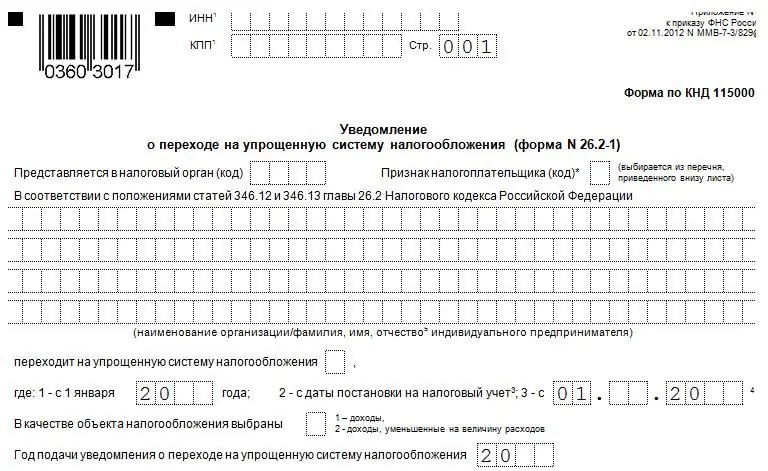

Using the simplified tax system: system features, application procedure

This article explores the characteristics of the most popular taxation system - simplified. The advantages and disadvantages of the system, conditions of application, transition and cancellation are presented. Different rates are considered for different objects of taxation

Indicators without delay and redrawing: types, principle of operation, pros and cons of application, expert advice

There is a wide variety of different tools in trading: graphical constructions, technical indicators, automated programs, trading signals and much more. To successfully apply them in trading, you need to understand how they work. Indicators without delay and redrawing are especially popular with traders

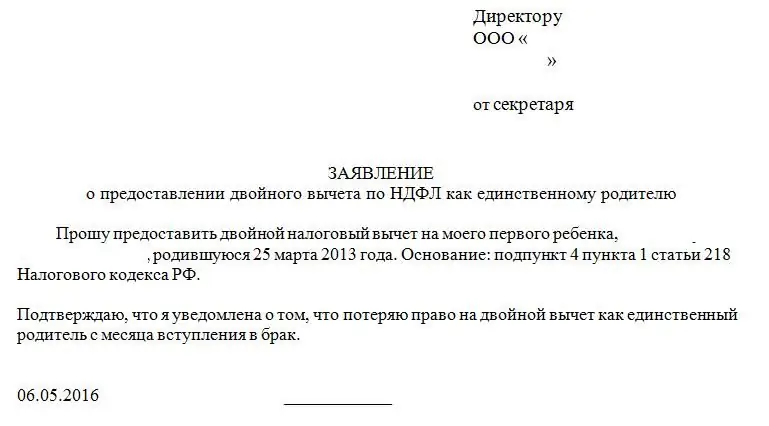

Tax deduction at birth of a child: application, who is en titled to a deduction, how to get

The birth of a child in Russia is an event that is accompanied by a certain amount of paperwork. Parents acquire special rights when replenishing the family. For example, for a tax deduction. How to get it? And how is it expressed? Look for the answer in this article

Application for the return of loan insurance: sample, application rules, submission deadlines

In the process of obtaining a credit loan, banks offer potential borrowers to conclude an insurance contract. If the client is unable to pay off the debt, the obligation to close it to the bank lies with the insurance company. But in practice, the opposite situation often arises, and conscientious payers are wondering about the possibility of returning insurance on a loan in case of early repayment. But how much will be received? And who should give the money - the insurer or the bank?

Production of LDPE bags as a business

Before, plastic bags were used very rarely. But now they are in demand in various fields, as the products are convenient and cheap. Therefore, the production of LDPE packages will be a popular business, because the demand for such products is always stable. More about this in the article