2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:41

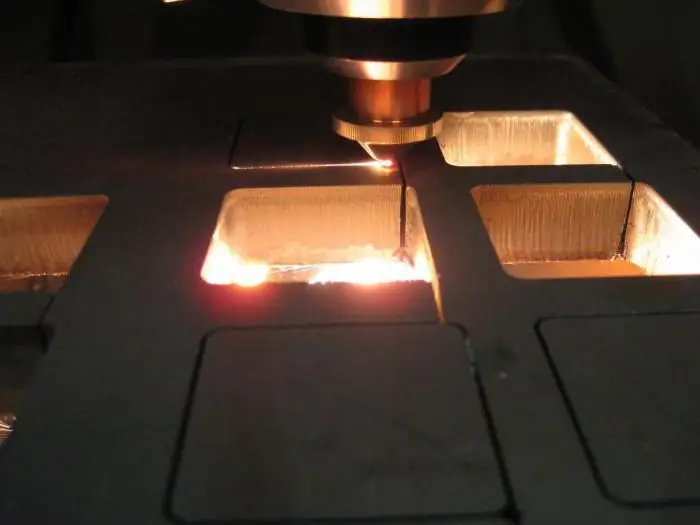

Metals can be connected in different ways. The most reliable and progressive way to obtain permanent joints of various products is laser welding. Thanks to this technology, it is possible not only to achieve great precision and accuracy, but also to join materials with a high melting point or high thermal conductivity. The short, controllable melting period and low melt volume make it possible to weld even parts where conventional methods are not at all suitable.

Technology Features

Laser welding is different in that the laser beam allows for a high concentration of energy at a point whose diameter does not exceed a few micrometers. The power level reaches 10 ^ 8 W / cm2, which is much more than, for example, an arc gives. In terms of energy concentration, laser welding can only be compared with electronicbeam (its power is about 10^6 W/cm2). But if the latter can only be used in a vacuum chamber, then laser welding can be carried out in an environment with some kind of protective gas (CO2, He, Ar) or simply in air. As for control, it is carried out using an optical system. Laser welding is carried out in a fairly wide range of modes, and this provides a high-performance process for joining all kinds of materials, the thickness of which starts from a few micrometers and reaches several tens of millimeters. Despite the fact that this process is very complex and there is still no universal theoretical model that could describe it in its entirety, it is widely used in practice, and for good reason.

What is good about laser welding of metals

The undoubted advantages of this method include the following:

- High performance of this technology compared to other methods.

- Small heat-affected zone limited by the laser diameter alone. This allows you to get greater technological strength and ductility of the connection.

- Ease of operation and the ability to change the processing program.

- Sustainability. A modern laser welding machine eliminates the need for auxiliary welding consumables and fluxes.

- Possibility of high-quality joining of dissimilar metals.

- It is often possible to avoid the use of consumables.

- Opportunitywelding in hard-to-reach places.

For welding of metal parts, gas and solid-state lasers are used, both continuous and intermittent. The application of the described technology directly depends on the capacity of the installations. Thus, lasers, whose power lies in the range of 100-500 W, have long been used for welding small-sized components, for example, electronic components or medical devices. And machines capable of concentrating higher levels of energy (in the kilowatt range) are often used in conjunction with robots and fiber optics. They are almost indispensable in the automotive, mechanical engineering, shipbuilding and other industries.

Recommended:

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Solid-state laser: principle of operation, application

This article shows what are the sources of monochromatic radiation and what advantages a solid-state laser has over other types. Here it is described how the generation of coherent radiation occurs, why the pulsed device is more powerful, why engraving is needed. It also discusses the three mandatory elements of the laser and the principle of its operation

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities

Welding converter: principle of operation

Currently, the process of welding to connect any structures is used quite actively. Experienced welders know that with direct current, the arc burns more stable than with alternating current, which means that the quality of the weld will be higher. The welding converter plays the role of a transformer that converts AC to DC

Ytterbium fiber laser: device, principle of operation, power, production, application

Fiber lasers are compact and rugged, point precisely and dissipate thermal energy easily. They come in many forms and, having much in common with other types of optical quantum generators, have their own unique advantages