2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

This article shows what are the sources of monochromatic radiation and what advantages a solid-state laser has over other types. Here it is described how the generation of coherent radiation occurs, why the pulsed device is more powerful, why engraving is needed. It also discusses the three essential elements of a laser and how it works.

Zone theory

Before we talk about how a laser (solid-state, for example) works, we should consider some physical models. Everyone remembers from school lessons that electrons are located around the atomic nucleus in certain orbits, or energy levels. If we have not one atom at our disposal, but many, that is, we consider any volumetric body, then one difficulty arises.

According to the Pauli principle, in a given body with the same energy there can be only one electron. Moreover, even the smallest grain of sand contains a huge number of atoms. In this case, nature has found a very elegant way out - the energy of eachelectron differs from the energy of the neighboring one by a very small, almost indistinguishable amount. In this case, all electrons of the same level are "compressed" into one energy band. The zone in which the electrons most distant from the nucleus are located is called the valence zone. The zone following it has a higher energy. In it, electrons move freely, and it is called the conduction band.

Emission and absorption

Any laser (solid-state, gas, chemical) works on the principles of electron transition from one zone to another. If light falls on the body, then the photon gives the electron enough strength to put it in a higher energy state. And vice versa: when an electron passes from the conduction band to the valence band, it emits one photon. If the substance is a semiconductor or dielectric, the valence and conduction bands are separated by an interval in which there is not a single level. Accordingly, electrons cannot be there. This interval is called the band gap. If the photon has sufficient energy, then the electrons jump over this interval.

Generation

The principle of operation of a solid-state laser is based on the fact that the so-called inverse level is created in the band gap of a substance. The lifetime of an electron at this level is longer than the time it spends in the conduction band. Thus, in a certain period of time, it is on it that electrons “accumulate”. This is called inverse population. When past such a level dottedelectrons, a photon of the desired wavelength passes, it causes the simultaneous generation of a large number of light waves of the same length and phase. That is, the electrons in an avalanche all simultaneously pass into the ground state, generating a beam of monochromatic photons of a sufficiently high power. It should be noted that the main problem of the developers of the first laser was the search for such a combination of substances for which an inverse population of one of the levels would be possible. The alloyed ruby became the first working substance.

Laser Composition

The solid-state laser does not differ from other types in terms of its main components. The working body, in which the inverse population of one of the levels is carried out, is illuminated by some light source. It's called pumping. Often this can be an ordinary incandescent lamp or a gas discharge tube. Two parallel ends of the working fluid (a solid-state laser means a crystal, a gas laser means a rarefied medium) form a system of mirrors, or an optical resonator. It collects into a beam only those photons that go parallel to the outlet. Solid-state lasers are usually pumped with flash lamps.

Types of solid-state lasers

Depending on the way the laser beam exits, continuous and pulsed lasers are distinguished. Each of them finds application and has its own characteristics. The main difference is that pulsed solid-state lasers have a higher power. Because for every shotphotons seem to “accumulate”, then one pulse is capable of delivering more energy than continuous generation over a similar period of time. The shorter the impulse lasts, the more powerful each "shot". At the moment, it is technologically possible to build a femtosecond laser. One of its impulses lasts about 10-15 seconds. This dependence is connected with the fact that the processes of back-population described above last very, very little. The longer it takes to wait before the laser "shoots", the more electrons have time to leave the inverse level. Accordingly, the concentration of photons and the energy of the output beam are reduced.

Laser engraving

Patterns on the surface of metal and glass things adorn the daily life of a person. They can be applied mechanically, chemically or with a laser. The last method is the most modern. Its advantages over other methods are as follows. Since there is no direct impact on the surface to be treated, it is almost impossible to damage a thing in the process of applying a pattern or inscription. The laser beam burns out very shallow grooves: the surface with such an engraving remains smooth, which means that the thing is not damaged and will last longer. In the case of metal, the laser beam changes the very structure of the substance, and the inscription will not be erased for many years. If a thing is used carefully, not immersed in acid and not deformed, then for several generations the pattern on it will definitely be preserved. It is best to choose a solid-state pulsed laser for engraving for two reasons: solid-state processeseasier to drive, and it is optimal in terms of power and price.

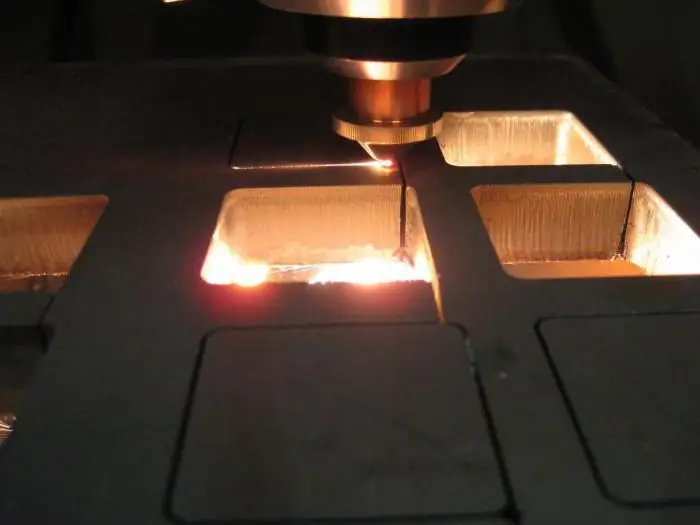

Installation

There are special settings for engraving. In addition to the laser itself, they consist of mechanical guides along which the laser moves, and control equipment (computer). The laser machine is used in many branches of human activity. Above, we talked about decorating household items. Personal cutlery, lighters, glasses, watches will stay in the family for a long time and will remind you of happy moments.

However, not only household, but also industrial goods need laser engraving. Large factories, such as automobiles, produce parts in huge quantities: hundreds of thousands or millions. Each such element should be marked - when and who created it. There is no better way than laser engraving: numbers, production time, service life will remain for a long time even on moving parts, for which there is an increased risk of abrasion. The laser machine in this case should be distinguished by increased power, as well as safety. After all, if engraving changes the property of a metal part even by a fraction of a percent, it may react differently to external influences. For example, break at the place where the inscription is applied. However, for domestic use, a simpler and cheaper installation is suitable.

Recommended:

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities

Laser welding: principle of operation and benefits

Metals can be connected in different ways. The most reliable and progressive way to obtain permanent joints of various products is laser welding. Thanks to this technology, it is possible not only to achieve great precision and accuracy, but also to join materials with a high melting point or high thermal conductivity. The short, controllable melting period and the small amount of melt make it possible to weld even parts for which conventional methods are not at all suitable

Ytterbium fiber laser: device, principle of operation, power, production, application

Fiber lasers are compact and rugged, point precisely and dissipate thermal energy easily. They come in many forms and, having much in common with other types of optical quantum generators, have their own unique advantages