2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

For many, the production of mineral water seems very easy. And at first glance it may seem so. After all, nature itself took care of the quality and benefits of the product. And the entrepreneur only needs to drill a well and put on a tap so that water flows into bottles immediately. This is only a superficial knowledge of the process. If you take a deeper look at the issue of mineral water production, then there will be a lot of nuances, without which it is impossible to set up the quality work of a plant for bottling medicinal drinks.

Mineral waters

In order to understand how complicated the production process of bottled medicinal water is, let's look at what mineral waters are. Firstly, it is a mineral that is formed in the bowels of the earth and pours out to the surface or is mined using drilling rigs. But where does the water come from in the earth's thickness? There are several hypotheses for the formation of mineral waters:

- Water,trapped in the thickness of the earth as a result of the process of infiltration (leakage) from the surface.

- Water released from mineral rocks by metamorphic and volcanic processes.

- Water from buried reservoirs in the process of sediment accumulation.

In the future, water circulates in the thickness of geological rocks and undergoes various changes: it is saturated with s alts, gases, radioactive elements and organic components. As a result of a long time, under the influence of external factors, underground waters with a unique composition are formed, which a person has learned to use for medicinal purposes.

The healing properties of mineral waters have been known since antiquity. Many rulers organized places near the springs flowing to the surface where they could improve their he alth. Mineral waters were used for baths, inhalations or simply ingestion. Depending on the composition of the dissolved components and their concentration, mineral waters have different purposes. The article will only consider water used for food purposes.

Types of mineral waters

Depending on what defining features are used for separation, mineral waters are differentiated into different types. Consider the most popular classification by the concentration of dissolved elements:

- Table mineral water. The concentration of dissolved substances is less than 1 g/l. Such natural drinks can be freely used in daily life without restrictions, like drinkingwater.

- Medicinal dining rooms. The concentration ranges from 1 to 10 g/l. These waters have healing properties due to the higher s alt content in the solution or the presence of biological components. Applicable without restrictions.

- Medicinal waters with s alt content over 10 g/l. The intake of such waters takes place only under the supervision of a doctor according to a strictly planned plan.

The first two types of water are freely sold in any supermarket or pharmacy, and in order to drink an ionic-cationic cocktail, you do not need to ask permission from a doctor. The situation is different with medicinal mineral waters. Their consumption is possible only according to a certain scheme drawn up by a doctor. In supermarkets, you won’t find a bottle marked “healing mineral waters”. In order for the effect of the intake to be positive, it is recommended to use medicinal waters only in balneological sanatoriums or mineral resorts.

Beneficial effect of mineral waters

Everyone knows that, first of all, mineral water, when taken orally, has a beneficial effect on the gastrointestinal tract. Treatment of kidney diseases can occur with the help of healing drinks. Also, table and medicinal table waters can be used for inhalation to help the upper respiratory tract with diseases.

Mineral water extraction

It is known that mineral waters are extracted from the depths of the earth by drilling wells. Sometimes their depth is more than one and a half thousand meters (for example, a well for the extraction of mineral waters "Borjomi"). It happens,that water itself finds its way to the surface of the earth through cracks in rock layers.

To preserve the uniqueness of natural deep waters, it is necessary to ensure the isolation of the extraction process. Mixing of mineral waters from different aquifers is strictly prohibited. For this, specialists carefully develop a project for drilling a future well. It must contain a clause on the liquidation or conservation of the well. And in order for the extraction of mineral waters not to be considered barbaric, it is necessary to take into account how much water will flow during self-spillage. After all, only in this way the healing liquid pumped out of the depths will resume again.

Technology for the production of mineral and drinking water

Before bottling mineral water, which has risen to the surface through the wells, it is necessary to go through several more stages of production. About each in order:

- Water spilled from the well first enters a special container, in which it accumulates for further production.

- The next step is cooling. Firstly, many mineral waters have a specific smell, which disappears when cooled. Secondly, the low water temperature is comfortable for bottling.

- After the water is purified from various impurities using filters. Natural environmental materials are used as cleaning agents: coal, sand, etc.

- Bacteriological safety of water is ensured by the stage of ultraviolet exposure to water. It is the spectrum of lightable to destroy harmful microorganisms while not disturbing the structure of water.

- Enrichment with carbon dioxide. This event is held in order to preserve the beneficial properties of mineral waters for a long time. Plus, sparkling water tastes better to drink.

- Blowing plastic bottles from special blanks.

- Bottling of products into containers and transportation to the warehouse. After forwarding to the point of sale.

Equipment

In order for the mineral water plant to work, it must be equipped with special equipment:

- Special reservoirs (large tanks) where water from the well will accumulate.

- Pumps that will pump water through pipes.

- Filters for water purification from unwanted mechanical impurities.

- UV lamps for water disinfection.

- A device designed to saturate water with carbon dioxide.

- Water dispenser for containers.

- A device that will blow plastic bottles from blanks.

- Labeling machine.

- A device that automatically or semi-automatically seals bottles hermetically.

- High volume sterile containers that will store purified water for bottling.

For quality control at the plant, it is necessary to organize a laboratory in which the chemical composition of the source waters and their safety, as well as compliance with the standards of the finishedproducts. It is desirable to have a warehouse for storing manufactured goods on the territory of the enterprise.

Mineral Water Business

Despite the fact that today there are many factories in the country and abroad that are engaged in the extraction and bottling of mineral waters, this direction remains promising. Firstly, this is due to the fact that the raw material base is unlimited, because with proper operation of the well, the supply of mineral water is restored. To create a full cycle of production of special units, it will take a little, the technology for the production of mineral water does not contain complex schemes and stages. Secondly, the equipment is different in price: from inexpensive to exclusive. Thirdly, the damage to nature is minimal (unlike, for example, wastewater from the production of mineral fertilizers). The profitability of such an enterprise is about 30%. The equipment will be able to pay off within a year.

Recommended:

Mineral fertilizers. Plant of mineral fertilizers. Complex mineral fertilizers

Any gardener wants to get a good harvest. It can be achieved on any soil only with the help of fertilizers. But is it possible to build a business on them? And are they dangerous to the body?

Paving stone production: equipment, technology

The article is devoted to the production of paving stones. The equipment and technologies for the manufacture of various materials of this group are considered

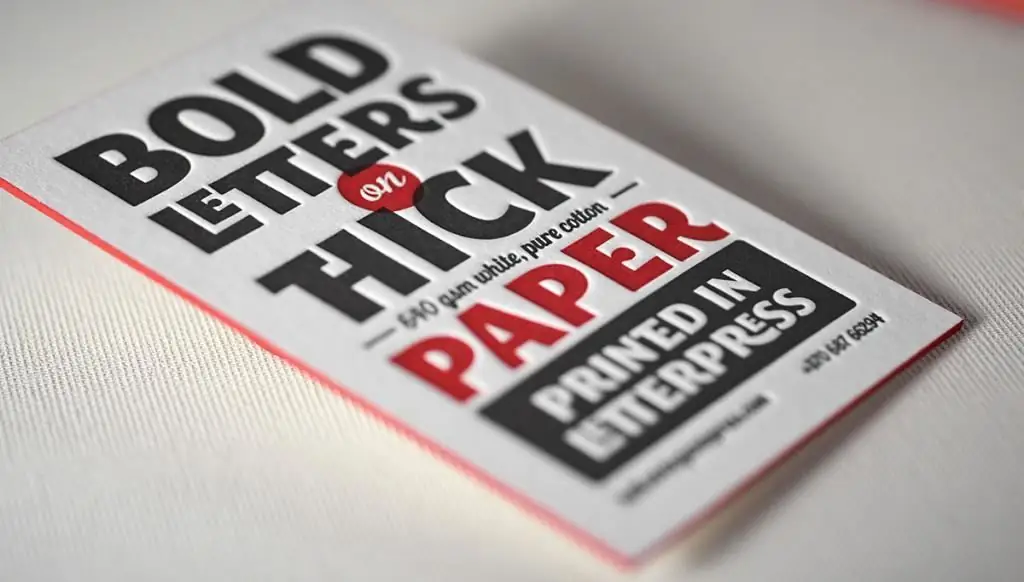

Letterpress is Letterpress printing technology, modern stages of development, necessary equipment, advantages and disadvantages of this type of printing

Letterpress is one of the typical methods of applying information using a relief matrix. The elements that protrude are covered with paint in the form of a paste, and then pressed against the paper. Thus, various mass periodicals, reference books, books and newspapers are replicated

Production of plywood: technology, main stages of the process and areas of application of the material

Plywood is one of the cheapest and most practical building materials. Despite the multi-layer structure, it is easy to install and can be processed at home without special equipment. Standard production of plywood involves the use of wood lamellas, with proper processing of which you can get a finishing material that is resistant to a variety of threats

Production of nitric acid in industry: technology, stages, features

Nitric acid is one of the most demanded substances in various fields of production. How is it commercially produced?