2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

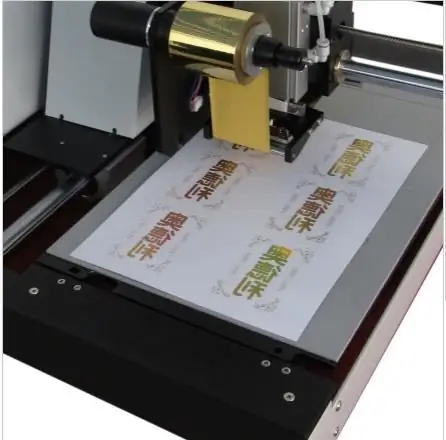

Embossing is a manufacturing process of post-printing finishing, applying images to printed or souvenir products using foil or without it, under pressure and high temperature.

Relief stamping

Embossing is used for making postcards, business cards, labels and other souvenirs. Embossing with foil looks the most impressive, the finished material has a presentable and colorful look.

Types of embossing:

- blind (blind) embossing - extrusion of the print below the surface of the material used without the use of foil;

- embossing - compressing material between a special cliché, matrix and male to give the image a convexity; can be blind or foiled;

- hot foil stamping is a process of thermal transfer of metallized powder from a film onto an embossed material by means of a cliché. Various types of foil are used - metallized, textured, pigmented, holographic, etc.

Embossing is widely used for finishing diary covers, as well as business card holders, purses and other products made of artificial and natural leather.

Clichefor embossing there are photopolymer and metal (zinc, magnesium, copper, brass, sometimes steel):

- photopolymer cliches are used for small runs (up to 1000 prints) - business cards and souvenirs. This is the most economical option;

- zinc plates are used in the manufacture of products up to 10,000 prints;

- magnesium clichés have their own advantages: the ability to print on any material, fast production, runtime (up to 50,000 prints). Has an impression depth of 0.7-2.5 mm (depending on the material);

- brass cliches are made on special engraving machines by machining. Advantages - the possibility of giving the cliche several levels of depth, giving the embossing elements a greater height. They are used on soft materials with multi-level embossing. Runtime depends on plate thickness (more than 50,000 prints).

Photopolymer plates are a photopolymer deposited on a metal substrate and protected by a film from light exposure.

Metal plates are made in two ways - etching (chemical) and milling (mechanical). Relief stamping and other types of hot stamping are mainly performed by chemically produced clichés.

Stamping foil has the following composition:

1) lavsan base;

2) a thermally degradable wax-resin layer that breaks down when heated, releasing the lower foil layers;

3) paint layer (lacquer or paint layer) with binder;

4)a thin layer of aluminum, present only on holographic and metallized foils;

5) adhesive layer designed to bond layers to the material.

Heated to the required temperature, the cliche frees the colorful layers from the lavsan base and sticks them to the embossing material. The heating temperature is selected depending on the type of foil, type of cliché, embossed material, print pattern, equipment used and many other factors.

Recommended:

Foil stamping at home. Cold and hot foil stamping

In order to make a gift or souvenir original and unusual, such an operation as foil stamping is often used. Also, using this printing technology, “wearable” leather items are often decorated, logos are applied to branded products, advertising panels are made, etc. If you wish, you can do embossing with thin metal yourself

Personal income tax benefit: who is en titled? Documents for tax relief

Individual income tax is commonly referred to as personal income tax. 2017 brought a number of changes for those who use tax credits. Rather, only certain categories of persons are affected. So, the amounts for deductions for parents with disabled children are changing. However, not only parents can receive tax benefits. However, you should provide a full package of documents, which will confirm the right to a tax deduction and a reduction in the tax base

Characteristics of the Su-35. Su-35 aircraft: specifications, photo of the fighter. Comparative characteristics of the Su-35 and F-22

In 2003, the Sukhoi Design Bureau began the second in line modernization of the Su-27 fighter to create the Su-35 aircraft. The characteristics achieved in the process of modernization make it possible to call it a 4++ generation fighter, which means that its capabilities are as close as possible to the PAK FA fifth generation aircraft

Sheet stamping of parts: technologies and features of the process

The article is devoted to sheet metal stamping. The features of this process, the advantages of the technology, the equipment used, etc. are considered

Stamping is a metalworking process. Types of stamping and equipment

The technological process in which workpieces are processed, which makes it possible to obtain flat or voluminous finished products of various shapes and sizes, is stamping. The working tool for this purpose is a stamp, which is fixed on a press or other equipment. Stamping is two types of technology that, depending on the conditions, are performed in a hot or cold way, and therefore both equipment and technological standards differ from each other