2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Due to its decorative features and many other properties, bronze has become popular. It is very difficult even for connoisseurs to name all the impurities and additives that are present in bronze alloys. This article will focus on bronze and its marking.

What supplements are available

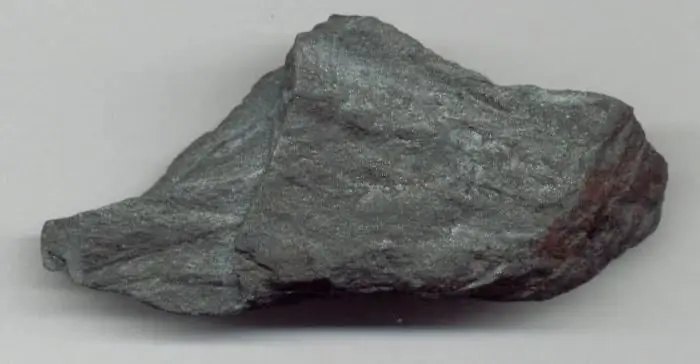

Bronze is an alloy of non-ferrous metals, based on copper, which determines the main part of its characteristic features. Man began to use metal in ancient times. This fact is confirmed by archeological excavations. At first they began to use bronze, which was based on tin. Bell alloy can be attributed to this category. Knowing the marking of bronze, you can understand what chemicals it contains.

In the composition of bronze, tin can replace other metals, for example, such as:

- Zinc or silicon. Thanks to these elements, bronze products are resistant to abrasion, and the fluidity of the metal becomes much less. This is important when performing foundry operations.

- Beryllium. The element is able to give the metal a highstrength.

- Aluminum. The element allows bronze to become more resistant, has anti-corrosion property.

- Lead. The alloy can also become resistant to corrosion processes.

In any bronze, the basis is copper. Many masters who know the markings of bronze can confirm this.

What is the chemical composition of bronze?

In addition to the division of bronze metals by chemical composition, there is a classification by processing technology:

- Foundry. Basically bronze alloy is made by casting.

- Deformable. Various products are cast, which are subsequently subjected to deformation.

In modern industry, a large amount of bronze is produced, which differs not only in chemical composition, but also in characteristics. Also, the marking of bronze is important in determining the scope of the alloy. Most craftsmen can easily determine which of the brands it belongs to. But, unfortunately, not many will be able to do this without knowing the appropriate markings. Deciphering the markings of bronze is the most reliable way to determine the composition. It is presented as numeric or alphabetic values.

Alloys that have been marked bronze in accordance with GOST with all the requirements meet all the necessary characteristics and are used in a variety of areas. Some masters do not use tables to determine the composition of the alloy, they only need to know the designation.

What the designation looks likemarker on bronze?

In order to decide which alloy is in front of you, just look at the markings of bronze. Bronze has an abbreviated marking in the form of "br". After this abbreviation, there are other elements (signs) that show what is included.

How are all added substances labelled?

For bronze metals, the marking does not indicate the amount of copper content. But there are numbers that display the percentage of other elements. Therefore, in order to find out how much copper is present in an alloy, it is necessary to calculate its content by percentage.

The properties of marked bronze must be known to craftsmen. The use of an alloy depends on what is in its composition and what are the properties of this metal.

What brands are available and where are they used?

Of course, the introduction of other elements into the composition of bronze is carried out to improve its properties. With a large amount of tin in the composition, the ductility of the alloy increases, and it becomes less brittle. But many craftsmen say that beryllium makes bronze more ductile and stronger. Many bronze alloys are stronger than most high-strength metals. Many begin to subject the alloy of bronze with beryllium to hardening so that it acquires high strength and elasticity. Springs, membranes and springs can be made from this alloy. Masters have found use for bronze marked Br. KMC 3-1 in mechanical engineering.

What properties does bronze have and where is it used?

From bronze alloys, inthe chemical composition of which includes aluminum, produce products with high strength and corrosion resistance. This alloy can be operated in any conditions and even at high humidity. If a product is being made that will be subjected to intensive use or strong impacts, it is recommended to pour lead into the bronze alloy. Bearings are made from this metal.

The classification of bronze by marking suggests that there are alloys that differ in properties. It mainly depends on the amount and type of chemical in the alloy.

What are the features of bronze metals that do not contain tin?

Bronze metal, which contains zinc and silicon, has excellent fluidity when melted. Thanks to this, experienced craftsmen make complex small parts from it. The main feature is that during mechanical actions, sparks will not occur on it. This condition is quite important for many masters.

The newest type of bronze alloys are alloys that include nickel and aluminum. They have a fairly high anti-corrosion property.

Marked bronze with various alloys does not have the property of magnetism, so it is used to make various electrical products.

How is bronze metal made?

During the long time of making bronze, only the tools have changed, but the essence has remained the same. For making alloycharcoal is recommended to prevent early oxidation of metals.

The melting process, after which bronze is obtained, is performed in the following sequence:

- It is recommended to place the container with raw materials in the oven, preheating to the recommended temperature.

- In order for the metal to not oxidize after melting, it is recommended to add coal to it.

- It is recommended to wait until it melts well, and add copper (phosphorous), which will play the most important role as an acidity catalyst.

- After the alloy has been aged, for some time it is required to add binding and alloying elements, they are also called ligatures. Next, it is desirable to mix the alloy well.

- Before you pour the metal, you need to add copper (phosphorous) again. In this case, it allows you to reduce the activity of oxidation processes.

It is required to closely monitor the temperature in the furnace at all stages and, most importantly, the temperature of the alloy itself. It is also desirable to monitor the amount of addition of all chemical elements to the alloy.

Marking of bronzes and brasses is made for convenience. By the way, brass is marked much more often than other alloys.

Masters use bronze with markings in areas of different specializations. They mainly produce parts for vehicles.

Artificial and natural patination

Many people are wondering why the old bronze metal pieces don't look normal buthave a greenish-white tint. This color appears when a small film is formed, which is called "patina". It is formed due to the content of various chemical elements in bronze.

This film is of carbonate and oxide origin, it is a kind of protective layer. The film allows you to make the product "noble".

In the modern world, there are some developments, thanks to high technology, they can be used to remove the surface layers of patina from bronze products. Also, some masters can perform patination artificially. This allows you to give the product a vintage look. This procedure is carried out using various means, which must necessarily include sulfur. After it has been applied, it is recommended to heat the product to the required temperature.

Positive aspects of bronze alloys

Due to its properties, bronze has practically no negative sides. You can only praise her constantly. The metal can be changed and added to the desired property at any time thanks to the addition of a chemical element.

Variety is the best quality of metal. Different types of alloys are used in completely different industries, because with the addition of any substance, you can get any excellent feature.

This metal can be used multiple times in a row because it can endure many repeated meltings.

Molten material is quite safe. Beryllium isthe most dangerous substance, but in the manufacture of metals, as well as their alloys, it becomes almost non-toxic.

Bronze is resistant to corrosion properties.

The main feature of many alloys is elasticity. Springs are made from the material, which are highly resistant and will also be durable in use.

If we consider the disadvantages, it will be the price of bronze alloys. Since copper and tin, although common in the world, are expensive.

Also, the disadvantage is a small heat transfer. But this was also directed in the right direction, they began to make products for bathrooms from bronze.

I would like to say that at the present time the scope of bronze, marking and properties are quite diverse. This is due to the different needs of the industries.

Recommended:

Bronze - melting point. How bronze items are made

The article talks about bronze, its classification, the method of melting and the manufacture of products from this alloy

Bronze is an alloy composition. The chemical composition of bronze

Many people know about bronze only that sculptures and monuments are cast from it. In fact, this metal is undeservedly deprived of popular attention. After all, it was not in vain that in the history of mankind there was even a Bronze Age - a whole era during which the alloy occupied a dominant position. The qualities possessed by an alloy of copper and tin are simply indispensable in many industries. It is used in the manufacture of tools, in mechanical engineering, casting church bells, and so on

Types of cast iron, classification, composition, properties, marking and application

The types of cast iron that exist today allow a person to create many products. Therefore, we will talk about this material in more detail in this article

Ductile iron: properties, marking and scope

Cast iron is a hard, corrosion-resistant, but brittle iron-carbon alloy with carbon content C ranging from 2.14 to 6.67%. Despite the presence of characteristic shortcomings, it has a variety of types, properties, applications. Ductile iron is widely used

Rock s alt halite: properties, description and scope

S alt halite is a natural mineral from which the well-known table s alt is obtained. The technical mineral has a number of properties, the application of which was found in 14,000 areas. The most common of them is the treatment of road surfaces in the fight against ice