2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Practically all people perceive information “drawn” rather than “listened” better. And even better, if this information is presented in images, and not a series of numbers and indicators. Imagine that a stranger is talking about his dog. He does not describe her appearance and pedigree, does not specify her color and age, etc. The imagination of each listener will draw its own image. And when we already imagine a handsome dog, it turns out that we were told about a lovely pug. In this situation, we will laugh, but faced with something like this in the enterprise, it will no longer be a laughing matter.

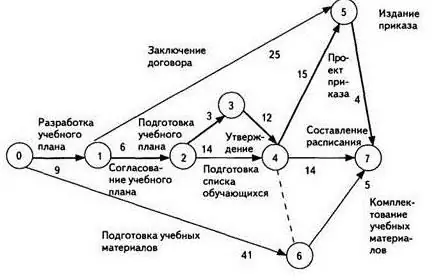

Therefore, in production, everyone is trying to visualize as much as possible. One of the most important documents, especially in construction, is the work schedule. We can safely say that the entire project without this schedule is a waste of time. Since it contains all the accepted engineering and technical solutions, as well as optimized deadlines.

What is a schedule?

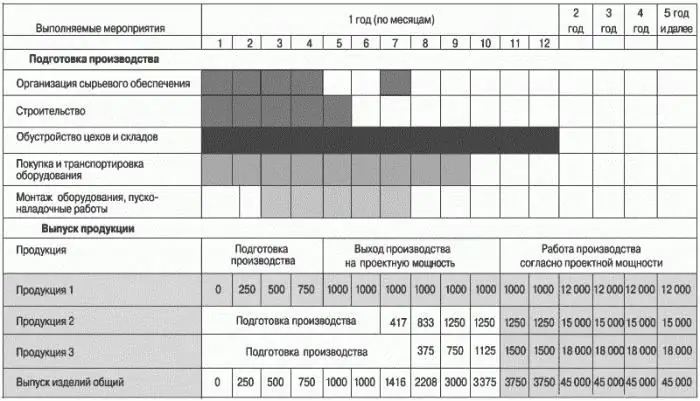

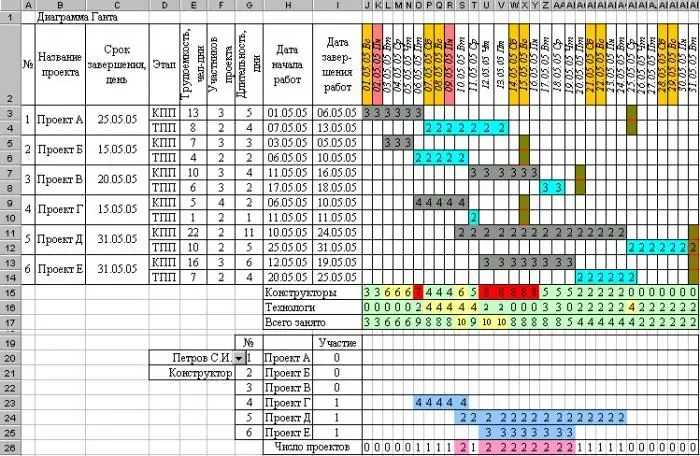

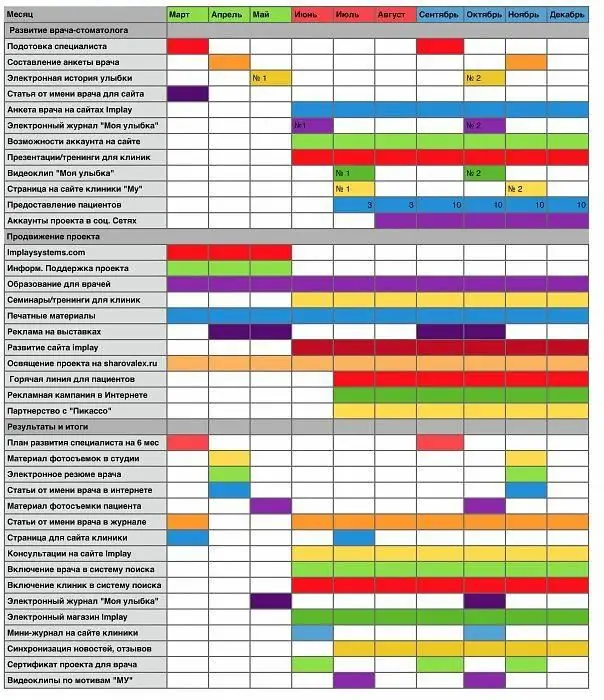

SamoThe title of this document gives an idea of its importance and significance. The calendar schedule for the production of works is a table that displays all types of work, their volume and deadlines. In addition, the graph clearly shows the sequence of work performed, tied to specific dates (or simply the duration of the execution of various types of work - for standard projects). Most often, this document also contains information about the resources needed at each stage of construction: basic materials, equipment and personnel.

The ability to schedule work is one of the most important skills of managers of different levels. The more accurate and detailed the schedule is, the better all the planned work will be carried out. Despite the fact that construction is considered the “native” industry of the work schedule, the knowledge of the principles of scheduling will not interfere with the leaders of all areas.

Where to start

Any job can be broken down into small tasks. The simplest example is the preparation of a salad of fresh vegetables. It would seem that it is easier? But even this elementary task can be broken down into a sequence of actions. First, purchase all the ingredients, then wash them, cut and mix, season with sauce. Moreover, all actions can be broken in time (breaks in work appear), or they can be done sequentially, without breaks in time. In addition, all this can be done by one person, or maybe a whole team of cooks. So, there is a sequence of actions. Remainscalculate the time to complete each stage and determine how many and what kind of personnel is needed for this work. And the work schedule is almost ready.

Regardless of the industry, when developing a schedule, you first need to highlight the scope of work: break the whole process into components. Moreover, the criteria can be not only technological differences, but also the number of employees, and the necessary mechanisms and devices, etc.

Due dates

After dividing the entire production process into a sequence of actions, you can begin to calculate the timing of the work. For production and construction, there are norms and standards, according to which specific terms are calculated for a given amount of work. For mental work, it is impossible to calculate the timing of the work according to the formula. But a manager with a lot of experience, who has information about his staff, can quite clearly set the time frame for solving the task.

Knowing the timing of each type of work, we can begin to determine the time needed to complete the entire process. It should be remembered that some tasks can be solved in parallel, and technological breaks are needed for certain processes.

Resource calculation

Of course, the staff is the most important element of the process. The schedule for the production of works in construction involves determining the number of performers, the specialization of workers and theirqualifications. At this stage, we calculate the number and composition of teams and draw up a calendar plan for their employment at the facility.

Next, we move on to determining the necessary equipment, mechanisms and fixtures. In manufacturing industries, there are also regulations for this. And finally, last but not least, is the calculation of the materials necessary for the work.

Calculation of material delivery times

All this information will allow you to combine the work schedule with the schedule for the supply of materials and equipment. Uniformity and continuity are the two main principles of planning. Optimizing the schedule in the direction of reducing the time may not give the desired result, because there will be a downtime due to a lack of materials (or, conversely, the construction site will be literally clogged with them, and therefore it will take a lot of time to find the right one at the moment).

Force majeure increases the turnaround time

Another important detail - when drawing up a work plan, it is necessary to foresee possible risks. For construction, this can be anything from bad weather to heavy traffic on the roads. Given the force majeure circumstances, it is necessary to slightly increase the timing of certain types of work. Most often, this also affects the duration of their entire volume.

Despite this, planners should not try to minimize time. After all, when the network schedule is violatedwork, the general contractor will have to pay a pen alty to both the customer and related contractors.

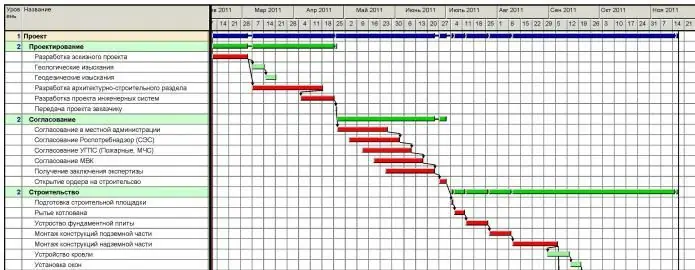

Automate plotting

Some years ago, the schedule was drawn up manually. The specialists calculated all the deadlines and the need for personnel and materials, and then visualized it using a graphic editor. For small jobs, this is a simple task. It's a different matter if we are talking about a serious contracting organization that manages several objects at the same time.

Programmers are developing a lot of auxiliary programs designed to automatically calculate and build a work schedule. A sample schedule calculated using Microsoft Office Project 2010 Professional, for example, is easily found on the Internet. However, not every company will agree to spend additional funds on installing software and training staff to work with it. In addition, each specialized program has its drawbacks. One does not take into account the possibility of shift work, the other without writing macros is not consistent with the calculation of materials, for example, etc.

That's why most planners have learned to build a work schedule in Excel.

This program has a lot of advantages:

- It's free. In the sense that Excel is part of the standard MS Office package, which is unconditionally installed on almost every computer.

- She's simple. With minimal knowledgeabout calculating formulas and linking sheets to each other, you can do planning.

- She is visual. All calculations and the result are displayed on one sheet. And the changes are immediately displayed on the chart.

Recommended:

Drafting a shift schedule: sample. Order to change the shift schedule: sample

Many questions are raised by such a task as scheduling shifts. You can always find a sample of this document, but there are many subtleties that will be discussed in this article

Quantum Internet - what is it, how does it work? Advantages. quantum network

Quantum internet is already a reality. Transmission using quantum data will someday be the beginning of a fundamentally new Internet, at present it has been carried out only in some scientific experiments from the field of quantum physics

Work permit for work in electrical installations. Rules for work in electrical installations. Work permit

From August 2014, Law No. 328n comes into force. In accordance with it, a new edition of the "Rules on labor protection during the operation of electrical installations" is being introduced

Production of wall calendars: types, selection of calendar topics, nuances of creating and printing

Calendar is an absolutely indispensable thing in every office. And no matter how many customers and suppliers donate them, they still magically spread through the company's offices that are not involved in communicating with counterparties. Simply put, the calendar is the most useful of promotional materials that always goes with a bang

Document flow schedule for accounting policy: sample. Regulation on accounting policy

Proper organization of workflow is the foundation of the enterprise, its development and financial success. Not only its production and economic indicators, but also the actual responsibility to state regulatory authorities depends on how effectively the infrastructure of the enterprise is built, and the movement of documents is organized in it