2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:39

Document lamination is a special coating procedure designed to protect printed products from damage of various kinds. This technology protects the paper from intentional or accidental damage and significantly extends its life, ensuring the safety and original appearance for an extended period of time. In addition, laminating documents significantly improves the readability of paper-type media, and also gives additional color saturation to images. The most common coatings are ID cards, book covers, cards, calendars, and other products that are at risk of being torn, dented, or filled with something due to their frequent use.

Today, paper lamination is most often used for advertising purposes, as it allows you to create reliable and high-quality advertising media in a short time and practically from improvised materials. Particularly relevanta procedure for applying a protective coating for high-wear products, such as business cards and advertising brochures. If necessary, you can also laminate photographs, diplomas, travel certificates and similar documents.

The coating procedure itself is divided into roll and batch. The latter is the most convenient and simple method for laminating single sheets of paper. The film used in this technology can be of various formats and types - both matte and glossy. If it is necessary to laminate a postcard, a card, a gift certificate and any other personal documents, in a salon dealing with operational printing, this will be done by batch method in just ten to fifteen minutes. Roll lamination of documents can be hot and cold. Hot coating technology is one of the most common and used methods in the printing industry. Lamination in this case is carried out on special installations, conventional (up to A4) or industrial format (up to A0). The equipment does not differ in a complex control system and is prepared for operation in just a couple of minutes, which allows printing houses to quickly work with large circulations. Cold lamination is a relatively new procedure that is only gaining popularity.

Over a long period of time, the coating process was limited in application due to the fact that it was carried out exclusively at high temperatures andgreat pressure, which far from any paper and paint could successfully withstand. The problem was solved with the invention of cold lamination technology, which made it possible to cover non-heat-resistant printed products and any synthetic materials.

You can order lamination of documents using this or that technology today in almost any online printing salon. The final cost will depend on the application technology, the thickness of the film used, the use of special effects, the required circulation and paper size.

Recommended:

Post-print processing of printing products

Printing is not always considered the final stage in the printing industry. Post-print processing is often required to protect the product from damage and give it a decorative look. This work is carried out by various printers. There are different types of post-print processing, which will be discussed in the article

Do I need to register the IP seal? Can IP work without printing

Does an individual entrepreneur need a seal? Is it subject to mandatory registration? The article will tell you in detail what types of seals are, who makes them and how to order a layout. And also, why an individual entrepreneur should still acquire a seal and register it with state bodies

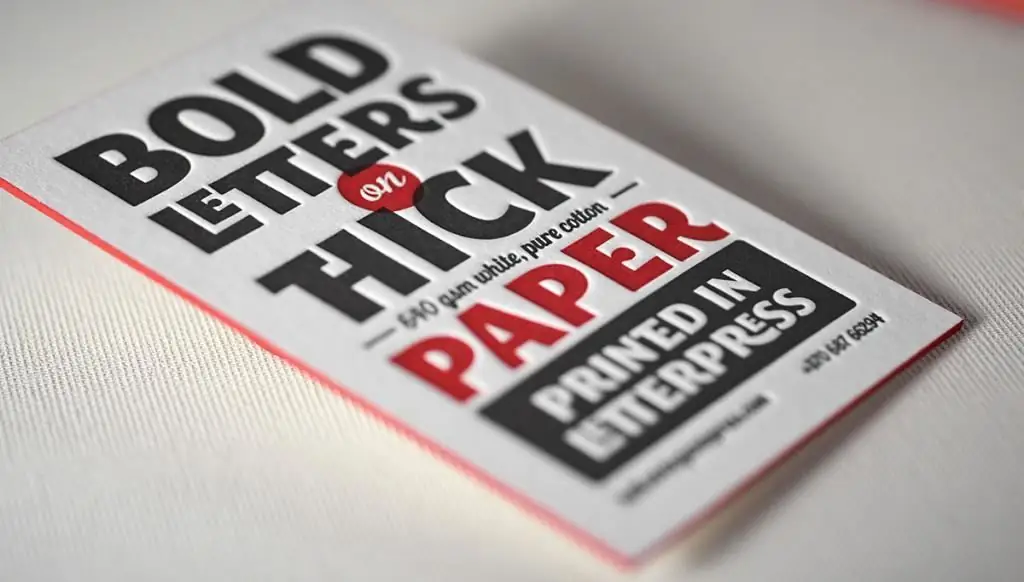

Letterpress is Letterpress printing technology, modern stages of development, necessary equipment, advantages and disadvantages of this type of printing

Letterpress is one of the typical methods of applying information using a relief matrix. The elements that protrude are covered with paint in the form of a paste, and then pressed against the paper. Thus, various mass periodicals, reference books, books and newspapers are replicated

Ink pad for printing

Many office workers have an ink pad on their desk, designed to soak the stamp in special ink. Even if it is not immediately visible, we can safely say that it is present, because in modern stamping equipment this device is hidden from view

Types of printing on T-shirts

All people love to dress stylishly. But summer is coming, it's time to take off your jackets and sweaters and put on something light. And that's where t-shirts come in. Yes, they can be boring and monochromatic, but there is another type - t-shirts with stylish and beautiful, witty and funny, bewitching and mind-blowing prints. These prints can be made with different technologies, which we will consider in this article