2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

An overhead crane is a device designed to lift and move loads along specially arranged tracks, most often inside a building. The scope of these devices is extremely wide, but they are mainly used in various heavy industries.

Design of overhead crane

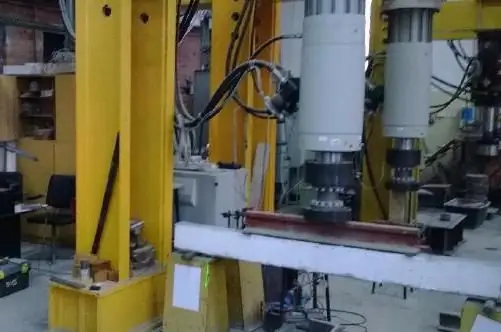

Any overhead crane consists of one or more span beams, end beams and a mechanism that lifts and moves the load along the bridge. Overhead cranes can be classified according to many parameters. One of the main ones is the number of beams in the bridge. A single girder crane has one span beam, a double girder crane has two. To perform various specific tasks - mainly in metallurgy - gigantic mechanisms of complex design are created. In the photo - an overhead crane with four span beams.

Depending on the design of the bridge, the layout of the lifting device changes. A special trolley is installed on a double-girder crane, on which lifting units are fixed. On thesingle girder crane uses an electric hoist instead of a trolley.

Hoist device

Trucks of double girder cranes are often also equipped with stationary hoists. Such an arrangement is called a telpher (or modular) scheme. It is mainly used on cranes with a relatively small lifting capacity - up to 50-60 tons. This is due to the fact that telphers with a higher carrying capacity are practically not produced anywhere in the world. The exception is China, which produces hoists up to 100 tons, but the products of the Celestial Empire are not yet in great demand outside of it.

Tail construction cranes are highly maintainable under certain conditions - the unification of equipment at the enterprise and the availability of a certain stock of parts. A lifting mechanism that has failed at a critical area of work is easily replaced by the same mechanism from a neighboring crane, which is temporarily idle. Modular cranes are also more compact and lighter.

For large double girder overhead cranes, the trolley arrangement is a so-called unfolded scheme. The lifting mechanism consists of the following main parts:

- motor;

- reducer;

- flexible coupling connecting the motor to the gearbox;

- brakes (mechanical, hydraulic or electromagnetic;

- rope drum.

In the case of a modular layout, everythingthe components are “packed” in the body of the hoist, while in the expanded scheme they are all located separately from each other in the open air. This makes it somewhat difficult to purchase spare parts in the event of a breakdown. The electric motor is produced by one company, the gearbox by another, etc. If the crane starts to break down during the post-warranty period, you will have to conclude contracts with a dozen different suppliers. But on the other hand, the design of an overhead crane with a deployed trolley allows you to create mechanisms of very large carrying capacity - 200-300 tons or more.

Movement mechanism

Support cranes move with the help of wheels fixed inside the end beams. Overhead crane beams use special travel trolleys attached to the top of the end beams and move along the bottom shelf of the crane track (I-beam).

Currently, there are two main types of travel drive for overhead cranes. Support cranes are moved with the help of motor-reducers, suspended cranes - with the help of electric motors. The motor-reducer consists of a motor and a gearbox that converts the torque of the motor and transmits it through the shaft to the wheel. On overhead cranes, the torque is transmitted from the motor directly to the wheels of the travel trolley by means of a gear. This gear is one of the most vulnerable parts of the design, since it carries a significant load when small.

Not all wheels and travel carts are equipped with motors. Often the crane has two drive carts and two "idle". Quantitytravel motors required on a particular crane is calculated based on load capacity, span length, operating mode, etc.

How much can a crane lift?

The main technical characteristic of an overhead crane is the weight it can lift. The world's largest crane operates in China, its lifting capacity is 20,000 tons. He is able to lift such a weight at a speed of 10 meters per hour. The crane is used to assemble oil platforms. The crane is used to assemble oil platforms. But this equipment is unique.

The most common overhead cranes with a lifting capacity of 1 to 50 tons. This is enough to perform the vast majority of industrial work. However, to perform various specific tasks, cranes with a lifting capacity of 150, 300, or even 500 tons are manufactured. Most often they are used for the installation and maintenance of hydroelectric turbines, as well as nuclear reactors. In the latter case, cranes are made not only of impressive carrying capacity, but also of circular action - the so-called polar ones. Such a lifting unit moves along radial rails installed inside the power unit housing, thanks to the special design of the end beams.

The lifting capacity records are held exclusively by the supporting structure of overhead cranes, which is able to withstand enormous loads. Overhead crane beams are rarely available with a lifting capacity of more than 20 tons due to the fact that most of the world's manufacturers do not produce mobile hoists larger thanload capacity. In addition, in order for the tracks to withstand the mass of an overhead crane with such a load, they will have to be built overly powerful - it is easier and cheaper to install a support crane.

Load handling devices

In accordance with the nature of the transported goods, cranes are equipped with various lifting devices. Depending on their design, overhead cranes are divided into the following main types:

- Hook. This is the main, most common and versatile type of faucet. It is equipped with a load-handling hook, as a rule, with an automatic latch. It can lift any load, but not directly with a hook, but with the help of slings.

- Grab - designed for loading and unloading various bulk materials, as well as scrap metal. There are two types of grabs - in the form of a double bucket for unloading crushed stone, sand, etc. and in the form of a "claw" - for scrap metal or, for example, lumber.

- Magnetic. An electromagnet is installed as a load-handling device, controlled from the crane operator's cab or from the remote control. Used to transport sheets of metal.

- Foundry - equipped with special hooks for capturing containers with molten metal.

- Stacker cranes. Equipped with forks for picking up pallets with goods. Used in warehouses.

Also, on many overhead cranes there are various combinations of load gripping bodies - for example, magnetic grab cranes. Foundries are often equipped with auxiliary lifting mechanisms with conventionalhooks.

Suspension and support cranes

Another parameter by which overhead cranes differ is their location on the crane runways. The base crane moves along the rails like a locomotive, the overhead crane is located under the tracks and rests on the lower shelf of the I-profile serving as crane tracks.

As a rule, single-girder cranes (or beam cranes) are suspended. Overhead double girder crane is an extremely rare occurrence. Its advantage is that, due to the specifics of the design, the cargo can, moving along the bridge, go to the sides beyond the limits of the crane runways. To do this, the bridge design provides consoles - parts of the span beams that protrude further than the crane runways. This feature is useful when working in a room with a shortage of free space, when you need to somehow "shove" the load.

State Standards

Depending on the type of overhead cranes, there are several regulatory documents governing their manufacture:

- GOST 27584-88 - contains general technical requirements for the production of overhead and gantry cranes, their acceptance, storage, transportation, operating modes, etc.

- GOST for overhead electric single-girder overhead cranes No. 22045-89.

- GOST 25711-83 "Electric overhead cranes for general purposes with a lifting capacity of 5 to 50 tons".

- GOST for overhead single-girder overhead cranes No. 7890-93.

In addition to these basic standards, each crane must meet the requirements of many othersGOSTs - for painting, quality of welded joints, metal hardness, etc.

Working hours

The design of an overhead crane is highly dependent on the intensity of its operation in the future. According to GOST 27584-88, the operating modes of cranes are designated from 1K to 7K. Depending on this, the technical characteristics of the overhead crane, as well as the power of the metal structure (span and end beams) are calculated.

Modes 1K-3K, as a rule, correspond to cranes designed for minor and rare work, mainly for lifting any workshop equipment for the purpose of its repair and maintenance. The operation of overhead cranes with one span beam, according to GOSTs, should take place in a mode no heavier than 3K.

Medium duty 4K-5K has most of the cranes employed in the technological processes of the main production in a wide variety of industrial enterprises.

Heavy (6K) and very heavy (7K) duty cranes are most often found in metallurgical industries. These are real monsters among load-lifting mechanisms, they “plow” continuously for days on end, in a polluted atmosphere and at elevated temperatures. In the photo - an overhead crane at the foundry in the process of work.

Crane control

There are three ways to operate an overhead crane:

- Cabin. A special structure, usually fixed on the crane bridge, in which the controls are concentrated. Can be open or closed(glazed). The operator, sitting in a chair inside the cab, surveys the working area from above and controls the crane, following the instructions of the slinger.

- Radio control - this method appeared relatively recently, but is rapidly gaining popularity. Some systems allow the crane to be operated from a distance of up to 100 m. This dramatically increases operator safety and mobility.

- Cable remote. The simplest and cheapest control body. Mainly implemented on single girder cranes.

The two control methods are often combined in case one of them fails.

Overhead crane tracks

Rail type “P” rails or special crane rails of “KR” type are used to move the support cranes. The latter have a wider base, due to which the load from the crane is more evenly distributed over the support. Sometimes square steel bars are used as paths. The rails are installed on trusses attached to the walls of the building.

Suspension cranes move on I-beams, leaning on the lower shelf. Beams are attached to the ceiling of the building or on special flyovers.

Recommended:

Hydraulic stations for presses: types, specifications, purpose and practical application

Hydraulics is one of the oldest mechanisms in the operation of power equipment. The simplest representative of this type of units is a press. With its help, large compressive forces are provided in various industries with minimal organizational and operational costs. The quality of operation of the device will depend on which hydraulic station is used for the press - whether it meets the target design in terms of working properties and whether it is able to maintain sufficient force

Mineral wool density: classification, advantages and disadvantages, purpose of mineral wool and application

Mineral wool is the most popular type of insulation for an apartment or house. Today it is used by everyone, from builders to the owner of the apartment, who wanted to insulate the room. The simplicity of its installation allows you to immediately insulate the entire house (ceiling, walls, floor). We will study the features and characteristics of the named material further in the article

Equipment for agriculture: classification and types, purpose and application

Modern industry produces a variety of equipment for agriculture. It can be, for example, soil-cultivating equipment, as well as fodder, harvesting or sowing. Of course, tractors are also widely used on farms

Accounting and distribution methods for overhead and general business expenses

The profitability of any economic entity depends on the correct reflection and accounting of costs. Their optimization, control, distribution affect the cost of goods, reduce the risk of sanctions from the tax authorities. At the initial stage of activity, the company plans and forms a list of costs necessary for the implementation of production processes. An important aspect reflected in the accounting policy is the methods of distribution of overhead and general business expenses

Multi-purpose transport and combat helicopter Ka-29: description, specifications and history

Multi-purpose transport and combat helicopter Ka-29: history of creation, specifications, photos, purpose, features. Helicopter Ka-29: description, operation, modifications. How a Ka-29 helicopter crashed over the B altic: history and consequences