2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

Hydraulics is one of the oldest mechanisms in the operation of power equipment. The simplest representative of this type of units is a press. With its help, large compressive forces are provided in various industries with minimal organizational and operational costs. The quality of operation of the device will depend on which hydraulic station is used for the press - whether it meets the target design in terms of working properties and whether it is capable of maintaining sufficient force in principle.

Purpose of the unit

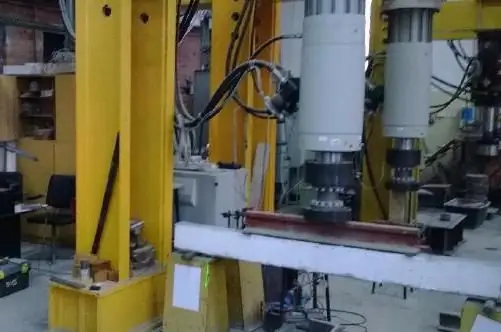

Hydraulic equipment is predominantly driven by differential pressure, which is controlled by a third-party pump unit. This is the hydroelectric station, which acts as a source of energy that is converted into mechanical force for the press. ByPneumatic presses and compressors interact in a similar way, where the working medium is not a liquid, but compressed air. To understand the specific technical tasks that the pump for the press hydraulic station performs, it is necessary to represent the entire technological process during the operation of the equipment. The object of pressing is placed on a platform connected to the piston of the machine. The pressure exerted on the press cylinder begins to increase when exposed to the small piston to which the station is connected. By changing the pressure indicator in the small piston, the operator logically affects the force acting in the main working cylinder and related working structures. In other words, under the action of the force of the pump, the large piston rises, as a result of which the object of processing rests against the platform and is compressed. At the same time, the configurations of the device and the press and the pumping stations may be different, not to mention differences in specific operating parameters.

Structural device

For industrial presses, full-scale pumping stations with electric drive and wide possibilities for regulating performance during the conversion process are usually used. The basic device of the hydraulic station for presses includes the following set of elements:

- Pump - usually gear.

- Electric motor.

- Filtration system - with membranes and screens that allow cleaning of working oils, water and other process fluids.

- Valve system - usedbypass, locking and adjusting elements.

- Gibrobak.

- Instrumentation - manometers, oil gauges and thermometers are mandatory.

- Couplings, fittings and adapters for making various connections of the pump and communications of the main equipment.

Varieties of hydropower stations

Differences in the technical and operational characteristics and conditions of use of different pressing machines also determine the need for constant expansion of the product range in the segment of hydropower plants. To date, several classification features have been formed that distinguish this equipment:

- A type of force support. Electric models are the most common, but in small industries and households it is quite advisable to use manual hydraulic stations for a press with a handle and a small cylinder volume of the order of 0.6-0.8 liters.

- The type of work environment being used. Again, the more difficult the tasks to be performed, the higher the requirements for the conditions for regulating pressure parameters. If simple pressing tasks can be supported by filtered water, then critical industrial machinery cannot do without the support of oil stations. The use of special oil media is characterized by less stress on the cylinder surfaces and a smoother piston stroke.

- Control method. The simplest hydraulic power plants for a manually operated press are completely dependent on the physical pressure exertedhandlebar operator. However, more modern electrically driven stations are provided with foot and remote controls that allow you to smoothly or stepwise adjust the force, perform automatic pressure relief and control the liquid level.

Technical specifications of equipment

Hydro stations involved in the maintenance of pressing machines usually have the following performance indicators:

- Tank volume - from 0.2 to 1000 l.

- Productivity - from 0.5 to 95 l/min.

- Working pressure - from 1.5 to 70 bar.

- Temperature Limits for Fluid Operation - Medium Range -20 to 70°C.

The lower level of indicators for the most part characterizes the capabilities of domestic hydropower plants for presses with typical manual control. As the same capacity and tank volume increases, the station moves to the professional segment with the expectation of use in workshops and manufacturing plants.

Application of hydro power plants

The entire workflow consists of a few simple steps:

- The unit is mounted on site. It is desirable to ensure the immobility of the structure. If the manual version is used, then it is necessary to hold the body of the hydraulic station for the press with your own hands in a stable position until the completion of the work cycle. Usually, for convenient physical handling of such equipment, pump kits provide specialclamps and other holding devices.

- To activate the pressure build-up process, either manual pumping of liquid through the handle is performed, or a special pedal with a button that opens the valve is held.

- The operation continues until the work cycle is completed, depending on the nature of the pressing process.

- When the operation is completed, you must release the working bodies or turn off the automatic pressure regulation button.

- The stem of the station returns to its original position.

Conclusion

Finding high-quality tooling to support the work of a hydraulic press today is not difficult on the market. Both domestic and foreign manufacturers of industrial equipment and construction tools present hydraulic power stations for presses in a huge range. For example, manual models of famous world brands like JTC and Trommelberg are estimated at 10-15 thousand rubles. If we are talking about work processes in a car repair shop or in the technological cycle of a processing plant, then a powerful station will be required, the cost of which can reach 200-300 thousand rubles.

Recommended:

Glass furnace: types, device, specifications and practical application

Today, people actively use glass for a variety of purposes. The glassmaking process itself is the melting of raw materials or charge. Glass melting furnaces are used to melt the material. They come in different types and are classified according to several criteria

Hydraulic system: calculation, scheme, device. Types of hydraulic systems. Repair. Hydraulic and pneumatic systems

The hydraulic system is a special device that works on the principle of a liquid lever. Such units are used in the braking systems of cars, in loading and unloading, agricultural machinery and even in the aircraft industry

What is a compressor station? Types of compressor stations. Operation of compressor stations

The article is devoted to compressor stations. In particular, the types of such equipment, conditions of use and features of operation are considered

What new metro stations have opened in Moscow. Scheme of new Moscow metro stations

The Moscow Metro is rapidly expanding beyond the Moscow Ring Road. There are cars on automatic control, the scheme of new Moscow metro stations is constantly updated

Household and industrial ironing presses. How to choose ironing presses? Reviews about ironing presses

A variety of ironing presses can be used to dry clothes. Today, these devices are rare in everyday life. However, in laundries they are quite in demand