2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:43

Increasing the rate of livestock production is impossible without creating and strengthening the forage base. The diet on farms should be developed in such a way that cattle receive all the vitamins, trace elements and nutrients necessary for their body. The menu of animals on farms usually includes three main types of food: concentrated, juicy and coarse. At the same time, cereals and legumes are of the greatest importance for poultry and pigs. But the basis of the diet of cattle and small cattle, which, of course, also need concentrates, is still roughage, that is, simply hay. The technologies for harvesting grass for the winter on farms, of course, must be followed exactly.

Economic value

They call hay a special, relatively inexpensive food obtained by drying mowed grass. Of course, you need to properly prepare and store such food for livestock. Cows, sheep, goats on farms should receive only high-quality nutritious hay without the admixture of herbs that can cause poisoning.

Good hay contains the amount necessary for the body of livestock:

- proteins;

- carbs;

- fat;

- micronutrients;

- macronutrients.

Hay is a fodder for cows, sheep, horses, of course, necessary. However, the concentration of nutrients in it is still such that it cannot provide too high productivity rates. In addition to hay, other types of feed should definitely be included in the diet of animals - cereals, legumes, beets, silage, etc.

Why technology is important

In a nutshell, winter haymaking is a process of cutting, drying and warehousing in compliance with certain grass standards. Hay can be a very good fodder. However, it is, of course, inferior to green grass in terms of nutritional value. After grazing in the meadows in the summer, cows, for example, are able to produce up to 18-20 kg of milk per day. When kept only on hay, this figure will drop to 8-9 kg. This is explained primarily by the fact that during drying, the grass loses up to 40% of nutrients and 70-90% of carotene. Compliance with hay harvesting technologies allows you to get the highest quality feed. That is, to minimize the loss of nutrients and carotene.

If the mowing technique is violated, among other things, part of the feed may also be lost. This, of course, is also unacceptable. Forage land on farms, of course, should be usedrational.

What causes losses

Follow the farms relies not only on the technology of harvesting hay, but also on its storage. Mowing the grass in the fields for cattle, small cattle and horses must first of all be done on time. Hay is supposed to be stored in such a way that it does not rot and does not lose vitamins, trace elements and nutrients. Also, farms, of course, must follow the feeding technology.

Hay harvesting dates

Single calendar terms for mowing grass for livestock, unfortunately, cannot be established for individual climatic zones of the country, but also for each specific farm. The growth and development of plants in meadows depend not only on the weather, but also on the composition of the soil, the presence or absence of fertilizers in it, etc.

That is, only the specialists of the farms themselves can determine the time of hay harvesting. The main factor to be guided by is the phase of plant development.

The first mowing of grasses for hay on farms is usually carried out in the phase of budding of legumes and earing of cereals. When harvesting such plants, it is especially important to observe the deadlines. Perennial grasses of this variety are significantly reduced in nutrients.

Alfalfa should be mowed at a time when the number of opened flowers reaches 10%. This allows you to get the most nutritious food. Forbs are mowed no later than the flowering phase of the main cereals. In this way, the good quality of the second wave herbs can be ensured. Also, the use of this technology increasesprobability of a third cut.

The grass mixture of clover and ryegrass is mowed in the flowering phase of the latter. Sometimes forage lands on farms are heavily clogged with coarse-stemmed plants. Such grass is practically unsuitable for livestock food. Mowing in such meadows and fields is supposed to be done before weeds bloom.

Hay harvesting: work order

After the grass is cut, it may be exposed to:

- flattening;

- Tedding;

- raking into windrows;

- stacking, stacking;

- pressed.

All these operations are, of course, subject to certain technologies.

What are the rules for mowing

This procedure in the farms in our time, of course, is done in a mechanized way. Mowers are usually used for harvesting hay as attachments for tractors. Also, sometimes special forage harvesters work in the fields.

When using any equipment on farms, the height of grass mowing must be observed first of all. This indicator depends primarily on the variety of plants. Field work on hay harvesting should be carried out in such a way that the cutting height is equal to:

- in the steppes and mountain meadows - 4-6 cm from the soil level;

- in the non-chernozem zone - 5-6 cm;

- on sagebrush meadows - 3-4 cm;

- for legumes - 4-5 cm.

Mowing grass too high results in loss ofpieces of roughage. But it is impossible to cut the plants in the meadows too low. This will lead to the fact that the yields of valuable grass in the coming years will decline.

The last cut of annuals on farms is usually done at the lowest cut. Perennial tops are cut 2-3 cm above the recommended level.

Condition rules

Technologies for harvesting hay usually involve drying it directly on the field. The grass is simply left to lie on the ground for a certain amount of time. When using this technology, plant stems usually do not dry out as quickly as leaves. This happens because of the unequal amount of water in parts of plants. Because of this, leaves may be lost during drying. To prevent this from happening, a procedure such as flattening is performed.

Perform this operation simultaneously with cutting grass or after mowing. In order for the plants to dry out evenly, their stems are simply flattened. This procedure should only be applied to fresh grass. Flattening already dried plants is useless.

Stack such grass in swaths. Being collected in rolls, it dries out at the same speed as not flattened. It is also believed that this procedure is best done in dry weather. Conditioning carried out during rain can cause the grass to lose a large amount of nutrients and carotene. It is especially advisable to carry out such a procedure for legumes and cereals. The stems of such crops are known to be of considerable thickness.

What is tedding

Conditioning significantly reduces hay drying time. But it is also possible to speed up the process of loss of moisture by grass through tedding. Such work on harvesting hay allows you to make the mowed mass more loose. Accordingly, the grass will be better ventilated. Tedding is especially important when mowing dense, high-yielding grasses. Plants in such fields lie in a dense thick layer. And without tedding, only the top layer will dry out in such layers. In this case, the lower grass remains green for several days, and then begins to turn yellow, which significantly reduces its fodder quality.

The first tedding is usually done immediately after mowing, without waiting for the top layer to dry. The second time this procedure is performed after drying the grass. Further, the frequency of tedding is determined by the type of plants, drying conditions, etc. In dry, hot weather, this procedure is usually performed no more than twice.

Raking

Grass is dried in mowing usually to a moisture content of 35-45%. Then the mass is raked into rolls. On steppe mowing plants can have a moisture content of 50-65%. In this case, swaths can be collected immediately - without pre-drying. Such work is carried out on the field for harvesting hay, usually with a transverse rake, for example, GP-F-10, GP-F-6.0 or GP-F-16.

The main purpose of collecting grass in rolls is to reduce the area of its contact with the soil. Plants laid in this way are well blown by the wind. In addition, sunlight does not penetrate into the thickness of the rolls. And this, in turn, allowsbetter quality hay.

As the grass dries up, the rolls are supposed to be wrapped one or more times. Also, plants collected in this way are raked from time to time.

Loose hay harvesting technology: stacking

The grass cut in the fields is kept in rolls until its moisture content drops to 22-25%. The hay is then stacked. Dried grass is brought to the storage site. It can be stacked in stacks on farms using two technologies: northern and southern. Sometimes dried grass is stored in this way right in the meadow.

Mow, folded according to northern technology, expands from the base to 2/3 of the height. Then it abruptly passes into the top at an angle of 60 degrees. This way of laying helps protect the hay from getting wet during rain. Water from such a stack falls from the widest part, and does not flow over the grass.

Stacks, folded according to southern technology, have sheer walls. This option is usually used in windy regions. In this case, even during a hurricane, the grass is not blown off the stack. This allows you to save the maximum amount of feed for livestock. When assembling according to both northern and southern technologies, low-value grass is usually placed on top of the stack.

How to form

Stacks are laid, according to the developed hay harvesting technologies, on farms usually as follows:

1. Lay out a rectangular base.

2. Gradually move to the middle, firmly trampling each layer.

3. Stack the top, toothickening her.

The technology of harvesting loose hay involves, among other things, the maximum compaction of the stack top. Otherwise, rainwater will subsequently penetrate into its thickness. After the assembly is completed, the stack is combed with a rake, creating a flat surface. Further, in order to prevent the grass from being blown away by the wind, its top is strengthened with poles.

Stacking

In areas with a small supply of hay and with limited possibilities for its transportation, stacks are usually collected rather than stacks. The latter have a round base and are formed in the form of a cone. At the same time, the execution is domed. During the formation of haystacks, they are carefully compacted.

Compacted hay harvesting technology

It often happens that hayfields on farms are located at a considerable distance from livestock farms. In this case, the grass is pre-collected in bales and rolls to facilitate transportation. Plants during both of these procedures are pressed. This procedure, in turn, can also be performed using several methods.

The technology of harvesting pressed hay looks like this:

- grass is picked up from windrows and put into balers;

- the finished bales are tied with twine.

Depending on the model of baler used, the weight of finished bales can be from 24 to 500 kg.

Hylage

Modern hay harvesting technologies make it possible to preserve a lot of useful for livestock in this type of feedsubstances. The main type of roughage used in keeping cattle is, of course, dried chopped, flattened or whole grass. But often on farms, haylage is also introduced into the diet of cows, which is an intermediate link between hay and silage. Such food is prepared from dried grass, pressing it in trenches. The moisture content of such a mass is usually 50-60%.

Ensiling

Providing cattle with quality food in winter, thus, first of all, allows the technology of harvesting hay and haylage. Silage is another type of roughage widely used in cattle breeding. It is also prepared from cut grass. However, the green mass in this case is not dried. When fresh, it is folded into silo pits, which are then hermetically sealed with an earth plug. The result is food that can be classified as coarse and juicy at the same time.

Crushed hay

Preparation of roughage for livestock using this technology is currently considered the most progressive method. Most often, cereal herbs are stored in this way. The technology of harvesting chopped hay provides for cutting the cut grass into segments 8-14 cm long. After such processing, the dried green mass is well ventilated and at the same time it fits quite tightly. Subsequently, it is very convenient to give such hay to cows. In addition, it is eaten by animals better.

Used equipment

Technologies for harvesting and storing hay, therefore, can be used differently. But in any case, such work is performed withusing special equipment. Can be used in hay making:

- mowers and forage harvesters (KPV-3, KPP-2, E-301, KSK-100);

- conditioners (for example, PTP);

- rake-tedders (GVR, GVK, etc.);

- cross rake (GP-F);

- stack throwers (PF-0, 5);

- balers (PS, PPL-F).

All these types of equipment can be mounted on tractors of different models. Hay harvesting equipment of this variety is used, of course, usually not too heavy - wheeled. In private farms, grass is harvested most often with the help of mini-tractors. Modern industry produces special mowers for such equipment.

Agricultural mowers

In the fields, of course, the technology of hay harvesting must be strictly observed. And machines of various kinds in this case, of course, are of great help in this. The main tool used in harvesting grass for the winter are mowers. Such equipment, in turn, is subdivided according to the number of cutting devices. Farms use 1-, 2-, 3- and 5-bar models. The design of all types of such attachments is almost the same. For example, the KRN-2.1A model, which is very popular with agricultural producers, consists of the following parts and assemblies:

- mounting frames;

- rotary cutter;

- balancing mechanism;

- hydraulic equipment;

- traction fuse;

- subframe;

- field divider;

- drive mechanism.

This mower can be aggregated with MTZ-80 and MTZ-82 tractors. When used for harvesting roughage, this equipment cuts the stalks with blade knives pivotally mounted on the rotors. These working tools rotate towards each other at a speed of 65 m/s. The cut green mass in the mower, having met with the engine shield, changes the trajectory of movement and falls into the swath.

What are conditioners

This agricultural equipment also belongs to the class of mowers. Conditioners differ from conventional models of this type in that their design additionally includes rollers or pin drums. Before mowing, such equipment is supposed to be adjusted. Stiffness in plant stems may vary. Accordingly, the pressure of the rollers when working on the field should be different. For grasses, for example, it will be higher than for clover or alfalfa.

Rake-tedder

Such equipment may differ primarily in the length and number of wheels. The main part of the design of such a rake are large-diameter discs with spokes bent at the top in the form of the letter C. A suitable tedder model can now be purchased for a tractor of any brand and power.

What are stackers

This technique can be used for stacking, loadingand transportation of piles. The main working body of the stacker consists of:

- clamping frame;

- rake grate.

Most often, when harvesting hay in our country, machines of this type SNU-0.5 A and SSR-0.5 are used.

What are balers

The technology of harvesting pressed hay from perennial grasses or annual grasses makes it possible to use the space of warehouses and storage facilities as rationally as possible. Dry grass is processed in this case using balers. Such equipment, in turn, can be rolled or bale. The first type of pick-up compresses the hay in a spiral. The sloping mass is pressed against the grid, which allows you to adjust the density of the roll.

Square balers form the cut mass into rectangular blocks. Such machines usually differ in larger dimensions and power than rolled ones. This technique is quite expensive. Therefore, farms in most cases use the technology of harvesting hay in rolls.

Hay quality

Sometimes the nutrients and carotene from dried grass are also lost during storage. This can happen because of:

- moisture penetration into the inner layers;

- development of putrefactive bacteria in hay cut too early;

- mold due to high humidity;

- reproduction in stacks of insects and rodents.

In order to reduce the loss of hay in stacks and under sheds, it is oftentreated with formic or propionic acid, as well as ammonia. The application rate of the latter is 2-3% by weight of hay. To preserve the quality of dried grass, as well as improve its palatability for livestock, you can use loose table s alt in the amount of 5-10 kg per 1 ton. Also, the surface of the stack can sometimes be treated with urea-formaldehyde resin, which forms an elastic film.

Where is the best place to store

According to the hay harvesting technologies developed over the years, stacks in some cases can be collected directly in the fields and meadows. But the most reliable storage of dry grass is provided in covered areas and in hay sheds. In order for the hay not to lose its qualities, in the rooms intended for its storage, among other things, ventilation can also be installed.

After stacking hay for storage for the next 10 days, its temperature is supposed to be checked daily. In the future, the observation is carried out 1 time in 5 days during the month. Further, the frequency of inspections is reduced to 2 times a month. The temperature in the stacks is measured with a special thermal rod. Insert this tool so that it reaches the middle of the laid mass of grass.

Features of storing hay outdoors

Storage in stacks, haystacks and stacks is the most economical hay harvesting technology. Thus, dry green mass can be stored indoors. But more often hay is still stacked in stacks on the street. In the open air, roughage for cattle, small cattle and horses is kept on pallets or pallets. This prevents the penetration of moisture into the lower layers of the dry mass. From contact with the sun and rain, hay is protected using a film or terpaulin. A well-ventilated, dry, elevated area is usually chosen for storing hay outside near the farm.

Bales of dry grass are usually stacked in a pyramid. This reduces the risk of wetting the grass to a minimum. The stacks on the fields have an end face towards the prevailing winds. It is believed that the moisture content of hay when stored outdoors should not exceed 18%. The forage yard itself on the farm, of course, must meet fire safety requirements.

Recommended:

Corn silage: cultivation, harvesting and storage technology

Corn silage is a valuable feed that can form the basis of the diet of various animals and birds. However, its harvesting is a complex process that will be useful for many agricultural workers to understand

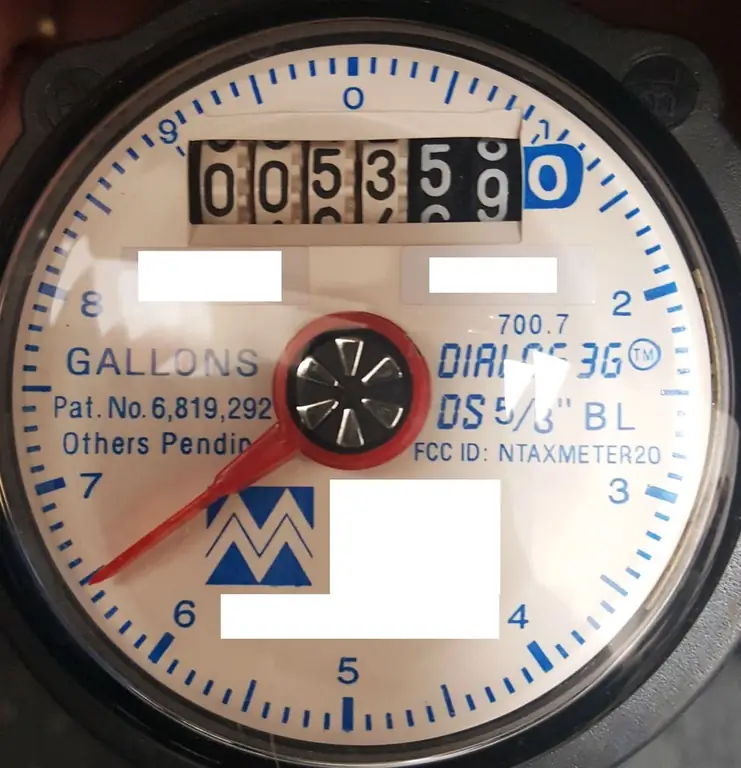

Shelf life of water meters: period of service and operation, verification periods, operating rules and time of use of hot and cold water meters

The shelf life of water meters varies. It depends on its quality, the condition of the pipes, the connection to cold or hot water, the manufacturer. On average, manufacturers claim about 8-10 years of operation of devices. In this case, the owner is obliged to carry out their verification within the time limits established by law. We will tell you more about this and some other points in the article

Diamond boring machine: types, device, operating principle and operating conditions

The combination of a complex cutting direction configuration and solid-state working equipment allows diamond boring equipment to perform extremely delicate and critical metalworking operations. Such units are trusted with the operations of creating shaped surfaces, hole correction, dressing of ends, etc. At the same time, the diamond boring machine is universal in terms of application possibilities in various fields. It is used not only in specialized industries, but also in private workshops

Duration of the operating cycle. What is an operating cycle?

The company will not have problems with a lack of current assets if the management begins to strictly control the proportions between equity and debt capital, through which operations are financed

Oil flax: cultivation technology, varieties, harvesting method, national economic importance

When cultivating flax, cultivation technologies, of course, must be observed exactly. The culture is relatively unpretentious. However, when growing it, like any other, it should be watered and fertilized on time. Also, under flax, you need to properly prepare the soil