2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:43

It would seem that such a type of work as cutting any type of meat is not difficult to handle. It is only necessary to cut out the necessary parts. However, in reality, everything is somewhat more complicated. There is a manual that shows how to boning, trimming, butchering a beef carcass and more.

General information about meat and processing procedures

As for, for example, boning, this procedure is subjected to meat on the bones, which is in a chilled, thawed, steamed and cooled state. It is quite important to observe a certain temperature regime in the thickness of the muscles before cutting the carcass of beef or other meat. Chilled and thawed carcass is considered to be the temperature of which is from 1 to 4 degrees Celsius. The steam product must have a temperature of at least 35 degrees. Cooled areas are considered to be areas with a temperature of no more than 12 degrees Celsius.

In addition, it must be added that the procedure for deboning, trimming or cutting a beef carcass can only be done after it has been examined by a veterinarian. If he gives permission, then the object can be passed for further processing. It is also worth adding herethat before proceeding to the procedure itself, the meat is weighed to categorize it. In addition, each type of product has its own characteristics.

As for beef, it is characterized by its color. This type of product is distinguished by a marble shade of meat, there are layers of adipose tissue in the areas of transverse cut muscles. By itself, this meat is quite dense, which creates some inconvenience when cutting beef carcasses, since you have to spend a lot of effort on it.

Storage temperature before processing

The processing process must be carried out in a strict order, observing the time of all operations. In addition, products vary greatly in their temperature condition.

For example, if after cutting a beef carcass or no later than 1.5 hours after slaughtering, the temperature of the hip part at a depth of up to 6 cm is 36-38 degrees, then this part belongs to the steam room. This type of product is best used for making boiled sausages, frankfurters, sausages, etc. In addition, beef is divided into several categories, which also greatly affects the processing and further use of the carcass.

As for the temperature regime, there are several more types. If, after cutting the beef carcass, the meat that was obtained was cooled at a temperature not lower than 12 degrees Celsius, and a dried crust appeared on the surface, then this belongs to the group of the cooled variety.

After cutting the beef, the pieces maysubjected to cooling at a temperature of 0 to 4 degrees Celsius. In this case, the muscles remain elastic, moisture from the surface disappears, and the dried crust also remains. After passing through this procedure, the products are considered chilled. After cutting the carcass of beef, the meat can have a temperature of -3 to -5 on the surface and from 0 to 2 degrees in the thickness. This type is called frozen, and the overall temperature of the entire carcass should be approximately at the level of -3 to -2 degrees. An object is considered frozen if its muscle temperature does not exceed -8 degrees Celsius. Thawed products are those whose temperature in the muscles reaches 1 degree, when creating artificial conditions.

Preparing for processing

The process of butchering a beef carcass requires the meat to be sent for processing to go through some preparatory steps.

- Before you transfer the carcass or half carcass for cutting, it is necessary that it be examined by a veterinary and sanitary doctor. The purpose of this inspection is to determine the commercial type of raw materials, as well as the possibility of its further use.

- If carcasses are received that have previously been chilled or thawed, they are cleaned of any contaminants, brands are removed, and blood clots are removed, if any. In some cases, it becomes necessary when, after dry cleaning, you need to wash the carcass. To do this, you must use water, the temperature of which is from 30 to 50 degrees Celsius.

- Frozen meat cannot beused for cutting, and therefore it must first be thawed. It can be added that frozen products must comply with the rules that are prescribed in regulatory documents in order to be used.

After passing the preparatory stage, you can start cutting the beef carcass. The technological process of this operation is quite different, depending on which part needs to be processed. It is also very important to understand here that cutting is a common name that includes several operations, namely, cutting the carcass into several parts, deboning the parts, that is, separating the pulp from the bones, as well as trimming (removing tendons, cartilage, films and etc.).

Cutting on the bones

In order to proceed to the deboning process, it is necessary to cut the half carcass of beef into several parts. This processing step is performed in six successive steps. It is worth adding that at this stage, an overhead path or a special cutting table with a slope for lowering individual parts is used as equipment for cutting beef carcasses.

- The first step is to cut off the scapula located between the muscles that connects the scapula and the chest.

- The second step is to cut off the neck part, located between the last cervical and first dorsal vertebrae, for this you can also use a billhook.

- The third step is cutting off the chest part along with the costal cartilage, in the place where the ribs are justconnect with these cartilages, and if we are talking about an old animal, then part of the beef, that is, the breast, you just need to cut off with a billhook.

- Fourth stage - cutting off the dorsal-costal part from the lumbar part, as in the case of the neck and spine, the incision is made after the last rib and in front of the first lumbar vertebra.

- After that, it is necessary to cut off the lumbar section from the hip part.

- The last step of cutting is cutting off the hip part from the sacrum with a billhook.

It is worth noting that initially the product comes in the form of carcasses, half carcasses or quarters. In any case, carcass meat must be cut in the manner described above. It can also be added that the forequarters and hindquarters entering processing are also separately separated into bran and go to the deboning stage. The forequarter is considered everything from the neck to the chest, including the dorsal-rib and scapular regions. The rest belongs to the hindquarter.

Bone deboning process

As mentioned earlier, the process of cutting a beef carcass, the photo of which will be presented, is divided into several large stages, and does not end with the fact that the carcass is simply cut. Deboning must be done next.

The process of processing the blades is somewhat different, and therefore it is worth considering in more detail and starting from the left side. The left shoulder blade is placed on the table with the outer side so that the forearm is turned towards the person. Thereafterit is necessary to begin to separate the meat part from the bone with the movements of the knife away from you. The movement should cover the area from the elbow to the shoulder joint and remove the meat from the humerus. The knife must go flat. After that, in the same way, cut off all the meat from the left humerus and scapula. Next, you need to hold the product by the radius, and by moving the knife away from yourself, separate it from the right side of the humerus. After that, you can cut the muscle tissue from the right side of the radius and the left side of the ulna. Here it is necessary to already lead the knife towards yourself, and not from yourself.

When the meat from this ledge is cut, it is necessary to pass the knife from left to right to cut the tendons of the elbow joint, and also to separate the elbow and radial parts from the shoulder. The two separated fragments are completely stripped. It is necessary not to touch only the interosseous space. The next step in cutting meat is done in this way. The shoulder blade rotates 180 degrees so that the bone is now turned towards the person. After that, you can start stripping the head of the bone. To achieve the result, it is necessary to make a small incision in the muscle tissue so that you can take it with your hand. With the fingers of the left hand, the meat stretches towards itself, and with a knife you need to lead along the surface of the bone towards you. With such a simultaneous effort, it will be possible to tear off the meat from the inside of the shoulder blade. Next, you need to remove the tendons of the shoulder joint. It is also necessary not to forget to clean both the outer and the inner part of the scapula from the film. It can also be noted that a slight presence of muscle tissue is allowed on the head of this bone.

Spinal costal region

In the photo of cutting a beef carcass, if you look closely, you can see that this area includes everything that is adjacent to the dorsal and costal vertebrae. With the correct cut, there should be 13 bones from each half. The vertebrae are interconnected by cartilage and ligaments. The ribs are presented in the form of long arcuate bones. There are two main methods for dorsal deboning.

First, you need to cut off all the available meat from the outside of the ribs, as well as the spinous processes of the dorsal vertebrae. Next, muscle tissue is cut out and the dorsal vertebrae are cleaned. Cutting the beef carcass into cuts from these parts can also be carried out on a conveyor table. In this case, the processing methods will just be different. In the event that the processing procedure is carried out by one worker, then the right and left parts are served on the table. When processing each of the halves, the meat is removed in the first step, that is, in the form of two large pieces. The right half is laid so that the outer part lies on the table, and the ends of the ribs look towards the deboner. By moving the beef carcass saw or knife from right to left, it is necessary to remove the remnants of the diaphragm. The next step is cutting the meat. In the direction from the 1st to the 13th rib, meat is cut from the dorsal vertebrae.

After that, it is necessary to turn the dorsal-costal part so that the spinous processes look towards the person. In this position, moving the knife away from you, cut off the core. The cleaning of the spinous processes themselves is carried out inin the opposite direction, that is, from the 13th to the 1st rib. The process of movement starts from the spine and goes towards the process.

Cutting carcasses for retailers

In order to successfully sell products on the retail market, you must first divide the carcass into half carcasses, and then divide them into two quarters. Cuts from the scapular, lumbar, dorsal and hip sections are considered the most valuable, in addition, they occupy almost 50% of the total mass. These departments are meant to carry out their implementation in kind.

During the culinary cutting of beef carcasses, some of the individual parts have their own names. In other words, the pulp that is located along the vertebrae is called the entrecote, the front dorsal part is thick, and the back is called a thin edge. It is also worth paying attention to the fact that when cutting a carcass for retail sales, it is divided into several varieties, depending on the amount of meat obtained. Cutting beef carcass by grade is divided into 3 types:

- First grade refers to cuts, the weight of which reaches 88% of the total weight of the half carcass;

- second grade only 7%;

- third grade is 5%.

It is worth considering that grade 3 cuts are the least valuable, since most often they consist almost entirely of bones, connective tissue.

Cutting up for processing

As described earlier, the beef carcass is cut into 7 parts in the event that it is necessary to produce infuture sausages, canned food. The scapular part was separated in the place where there are muscles connecting the scapular and chest parts, the neck cut was carried out in the place where the last cervical vertebra ends and the first dorsal vertebra begins, etc. However, if beef is cut, which belongs to the first or second category, then first the tenderloin is separated from the carcass, which is sent for processing to get semi-finished products.

It is worth noting that the conditional division into 7 parts and subsequent deboning differ only in that the processing of each of the departments differs in its complexity and labor intensity. The quality of meat in any area will be the same as in any other. Separation according to quality characteristics occurs only at the last stage of beef carcass cutting, that is, in the process of trimming. At this stage, the meat is divided into varieties, depending on what percentage of adipose and connective tissue is present in each individual piece.

Currently, many different cutting technologies are used. Initially, only trading cut schemes were used. However, in the future, combined schemes were developed for industrial facilities for cutting carcasses. According to the same standards, parts that have an increased culinary value must be sent to create semi-finished products, and everything else is sent to the sausage and canning industry.

Trimming of meat products

This procedure is also going according to a certain plan.

- First,trimming is carried out only after the deboning is fully completed. The essence of this operation is that all coarse tissue is removed from the meat, which is the connective tissue. The fat layer, large blood vessels and so on are also removed. This process is the last step in carcass cutting of beef or any other meat.

- Secondly, the procedure itself is carried out manually using a special sharp knife.

During this procedure, you must follow some important rules:

- Meat is cut into separate muscles or groups of them.

- Muscles are cut in the longitudinal direction. Pieces should be no more than 1 kg.

- If the meat will be used for the manufacture of raw smoked sausages, then the mass of the piece should not exceed 400 grams.

- The piece of meat that is being processed is placed with the connective tissue down. Using a trimming knife, the meat is separated from the connective tissue by moving the knife away from itself.

- It is quite important not to collect a large amount of deboned and trimmed meat on the work table to avoid deterioration of its quality.

It is also worth paying attention to the fact that in order to achieve the best quality of meat, it is necessary to carefully trim the meat. To do this, it is necessary that the production has workers who are responsible for processing individual parts of the carcass. In this case, the meat will be of the highest quality. In the production of semi-finished meat products, the quality of meat plays a crucial role. The presence of fat, films, lived and other things willdeteriorate the quality.

Beef trimming rules

Since the cutting of meat can take place according to different methods, depending on this, the products are divided into several varieties after trimming:

- can be divided into three grades: superior, first and second;

- into two grades: beef can be trimmed single-grade and natural semi-finished product;

- for two varieties, if there is a natural semi-finished product and trimmed sausage meat;

- maybe premium trimmed beef and trimmed sausage;

- the last kind is the usual trimmed single-grade beef.

In addition, it is also possible to produce large-sized semi-finished products, which are divided into three categories: the first, second and third. When cutting beef carcasses into steaks or for other purposes, or rather, it is at the final stage of trimming meat obtained from fairly well-fed livestock that has fat deposits, fatty meat is also isolated separately. Such pieces contain up to 35% of the total mass of fat and connective tissues. In order to obtain natural semi-finished products, as well as trimmed beef of the highest grade, it is necessary to process the hip, shoulder, dorsal and lumbar parts of the carcass. In addition, the average percentage of trimmed meat strongly depends not only on the fatness of the animal, the cutting technique used, but also on the qualifications of the workers working in the workshop.

One can only add that after deboning and before trimming, a slight cut of muscle tissue is allowed. It is also worth noting that the chest part, which is used formaking a soup set, should be processed only on one side, on the outside of the cut.

From all this we can conclude that cutting a beef carcass into pieces is, firstly, a procedure that is divided into three smaller ones: cutting, deboning, trimming, and secondly, this requires qualified specialists.

Recommended:

Technological processes in mechanical engineering. Automated process control systems

Technological process is the basis of any production operation. It includes a set of procedures carried out in a certain sequence, the action of which is aimed at changing the shape, size and properties of the manufactured product. The main examples of technological processes are mechanical, thermal, compression processing, as well as assembly, packaging, pressure treatment and much more

What is a technology project? Development of a technological project. Example of a technological project

As part of the article, we will find out what a technological project is, and also work out the issues of its development

Cutting mode for milling. Types of cutters, calculation of cutting speed

One of the ways to finish materials is milling. It is used for processing metal and non-metal workpieces. The workflow is controlled by cutting data

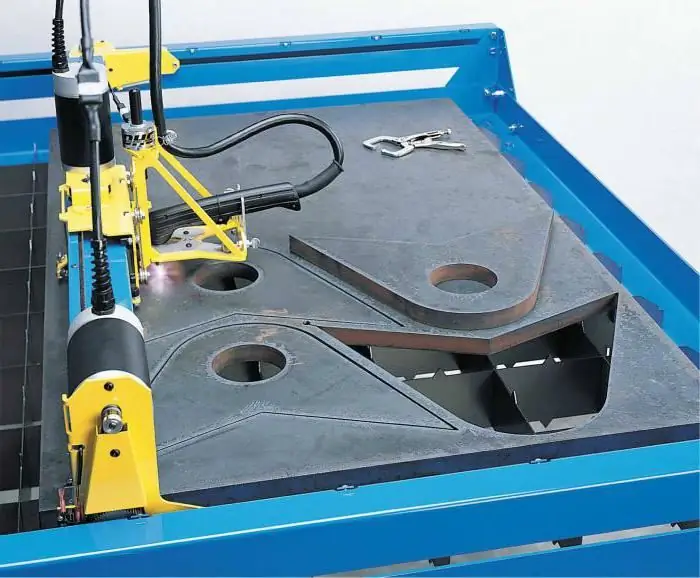

Metal cutting machine. Plasma metal cutting machine

The article is devoted to the apparatus for cutting metal. The technology of plasma cutting, as well as the device and features of the equipment are considered

Why is beef called beef? Features and interesting facts

Why is beef called beef? After all, the meat of a pig is pork, chicken is chicken, ram is mutton. The roots of the word "beef" is, according to some researchers, very ancient. This is how the meat of cows in the territory of present-day Russia has been called for more than one millennium