2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

Chillers are in high demand on the HVAC market. They are refrigeration units, the main task of which is to maintain the microclimate. The equipment is vapor compression and is installed in rooms for various purposes. The air during the operation of the devices is cooled, filtered and heated.

Which devices are the most popular

Devices can be included in the basic package of modern air conditioning systems. Technologies allow the production of two types of chillers, in which the work with the condenser is carried out using water or air. These two methods are widely used. But air-cooled units are the most popular, due to the lack of need for a coolant. In order to install such a unit, you need to familiarize yourself with the technology of work.

Main steps

Installation of a chiller is a rather complex type of work that requires a special approach andhighly qualified. The efficiency of the air conditioning system and the duration of its operation will depend on the correct installation. Considering the main stages, one can single out the design of the system, determining the installation site, as well as calculating the load on structures.

The next step is to prepare the base frame or base. The installation instructions for the MTA AS299 N chiller, like devices of any other brand, provide for rigging and installation of the unit itself. The system is connected to the heat carrier, as well as to the power supply network.

Before launch

The final stage is commissioning, then commissioning is carried out. When designing, calculations of heat inputs and coolant flow rates are carried out. This data allows you to choose the machine and its execution. After the chiller type has been approved, the installation site must be determined and properly prepared.

The main types of design - indoor unit and monoblock devices for outdoor installation. Internal equipment may include a water-cooled or remote condenser. If you have to work with a monoblock chiller, then a support frame is made for it, which must have a certain height. It protects the equipment from precipitation and evenly distributes the load on the structure. The support must be made in compliance with all the rules, because noise and abnormal vibrations may appear.

Working on the base and connecting

Installation of a chiller that willlocated from the inside, involves the organization of the site. Refrigeration devices operate with a significant level of sound pressure, so they should not be located near office and residential premises. It is important to select and correctly install vibration mounts, which will reduce the level of vibrations transmitted to building structures.

One of the most important stages is connecting the equipment to the heat carrier and power supply. In order to ensure the normal operation of the system, you should follow the recommendations for installation and understand which components should be in the hydraulic piping.

Elements for installation

Installation of the chiller is accompanied by the use of some elements. In the direction of movement of the coolant, a bypass and a filter with a shut-off valve should be located. This measure will prevent contamination of the heat exchanger when flushing the system, otherwise you may encounter equipment failure.

You will also need a balancing valve, which will be located at the outlet of the evaporator. It is required to adjust the water flow and bring the values to the norm. Shut-off valves will be located at the outlet and inlet of the chiller. If the system depressurizes, then the coolant will have to be drained.

You should take care of the presence of automatic air vents, they must be mounted at the highest points of the system. Installation of an absorption chiller is carried out in several stages. One of them is the installation of thermometers and pressure gauges before and after the described equipment. itwill allow you to monitor the temperature and degree of contamination of the heat exchanger.

A filter is installed in front of the pump. It must be facing in the direction of movement of the coolant. This will eliminate mechanical damage in the area of the pump impeller. The emergency valve and damping expansion tank must be located in front of the pump. This will eliminate the increase and decrease in pressure at the pump inlet.

Additional information about choosing a placement

Installation instructions for the chiller are included with the equipment. After reviewing it, you will be able to find out that you can place the device at ground level or on the roof, but in these cases, you must ensure that there is room for ventilation. The unit must be located taking into account the requirements that apply to vibration and noise.

The appliance should be protected from ultraviolet radiation by placing it away from chimneys. It must not be exposed to atmospheric air which could corrode the condenser coils and copper tubes. If the chiller can be accessed by unauthorized persons, then measures should be taken to restrict it. Protective devices are used for this.

The chiller is installed on a base that is 300mm or more high. It is important to provide drainage channels that will remove water and deal with leaks. When the unit is located at ground level, the base must be mounted on a concrete foundation, which is laid below the soil freezing line. The base must not come into contact withbuilding foundation to eliminate vibration and noise.

When installing the bases, it is necessary to ensure the presence of holes that will allow fastening to the foundation. When mounted on a roof, the roof must be capable of supporting the weight of the chiller and maintenance personnel. The device can rest on a base or a steel frame.

The steel channel should be aligned with the shock mounting holes. The channel must have a width that will be sufficient for mounting the shock absorber. When installing the chiller, it is important to eliminate obstacles for connecting water pipes and wires. The water inlet must be free from heat sources, steam, harmful gases and noise. Hot and cold air from the equipment must not affect the environment.

The need for extra space around the equipment

During installation work, technological features and requirements should be taken into account. For example, the installation volume should not be limited by the dimensions of the machine, it should include additional parameters, among them space:

- for air intake and exhaust;

- for access and maintenance;

- for replacement parts.

As for the first recommendation, it is true for air-cooled chillers that require air intake and exhaust to operate. There are also safety regulations, they dictate the rules in which space should be taken into account for maintenance andaccess.

No matter how high-quality the equipment is, one should take into account the probability at which the device may fail. Therefore, space must be left for replacement parts and repairs, which may be required for compressors and shell-and-tube heat exchangers.

Connection of fancoil and chiller

Installation of chillers and fancoils allows you to achieve the smooth operation of the system. The work involves the use of pipelines with thermal insulation. If there is no insulation, then the efficiency of the system will drop significantly. Fancoil units have individual piping units, with which you can adjust the performance in terms of heat and cold production.

The refrigerant flow is regulated by special fittings. If it is necessary to separate the heat carrier and the cold agent, the water should be heated in a separate heat exchanger. The circuit is supplemented with a circulation pump. For smooth adjustment of the fluid flow when installing the piping scheme, a three-way valve should be used.

If the building has a two-pipe system, then heating and cooling will occur due to the chiller. In order to make the heating work more efficient, fan coil units are connected during the cold period and supplemented by boilers. If we compare a two-pipe system with a heat exchanger with a four-pipe system, then the two mentioned nodes are laid in the latter. At the same time, the fan coil works for heating and cooling, using in the first case the liquid that circulates in the systemheat exchanger.

If you decide to install a chiller and a fancoil in the building, you can install a cooling system in Moscow. The cost of such work will be mentioned below. Speaking of the above, it can be noted that during installation one of the heat exchangers is connected to a pipeline with a refrigerant, while the second is connected to a pipe with a heat carrier. The heat exchanger must have an individual valve that is controlled by a remote control. If such a scheme is used, then the refrigerant does not move with the coolant.

In closing

Installation of chillers in Kaliningrad can be done with the help of specialists. Prices in Russia are about the same everywhere. The final cost will depend on the capacity of the equipment. If it does not exceed 100 kW, then you will have to pay 16,000 rubles. With an increase in the mentioned parameter to 250 kW, the price increases by 50 rubles. for every kilowatt. When purchasing a fan coil unit with a power not exceeding 6 kW, you will pay 2900 rubles for its installation

Recommended:

Quik: setup, installation, step-by-step instructions, features of work

The trading platform plays a very important role in trading. All transactions are made on it. In trading on financial markets, there are different terminals that have their own characteristics and characteristics. This article will talk in detail about the Quick trading platform. The reader will receive information about the correct Quik settings for different trading assets and its installation

Machines for furniture production: types, classification, manufacturer, characteristics, instructions for use, specification, installation and operation features

Modern equipment and machines for furniture manufacturing are software and hardware tools for processing blanks and fittings. With the help of such units, craftsmen perform cutting, edging and adding parts from MDF, chipboard, furniture board or plywood

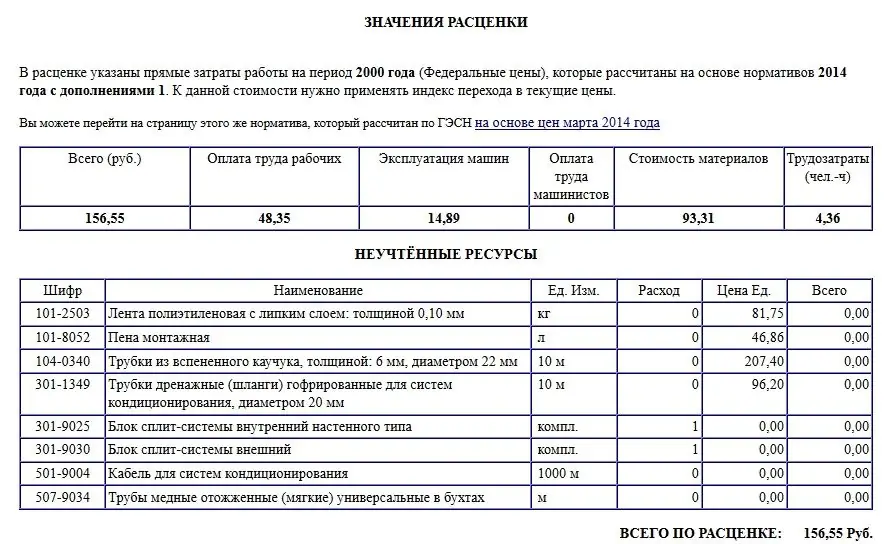

Step by step instructions on how to read estimates. An example estimate for the installation of a split system

How to understand the estimates? Examples of estimates for installation. Drawing up an estimate using the example of a local estimate calculation for the installation of a split system. Completion of estimates for installation work. Regulatory documents for determining the cost of construction products in the territory of the Russian Federation

HDPE pipe: do-it-yourself installation, installation features and instructions

When HDPE pipe is installed, the installation is done mainly by welding or compression fittings. If the installation rules are followed, the connections will be airtight and durable for many years

Industrial reverse osmosis plant: rules, installation instructions, filters and principle of operation

Industrial reverse osmosis plants: purpose, features of purification technology. Basic equipment and additional options. The main characteristics of the installations. Membrane types. Operating principle. Installation and commissioning