2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

Thanks to their absolute smoothness and brilliance, glass elements give any product a special charm. However, this material has a significant drawback - low strength and brittleness. Therefore, an alternative option is increasingly used in interiors - stemalite. What is it and how is it different from ordinary glass?

Help

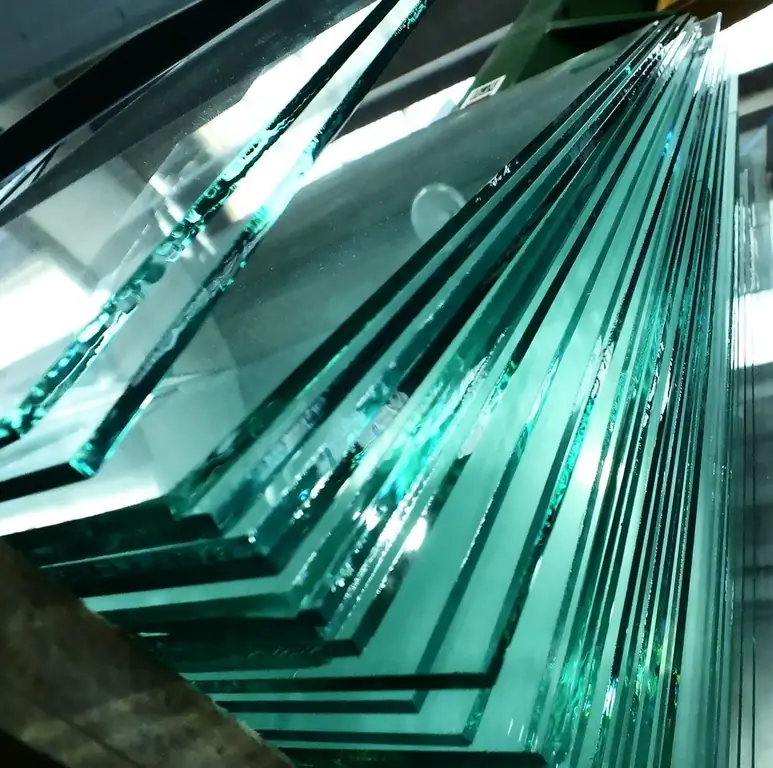

Stemalite is a high-strength enameled glass, one of the sides of which is coated with a layer of fusible ceramic paint. During the production process, it is subjected to additional heat treatment (firing), due to which the enamel is baked on the surface and becomes resistant to the environment.

Production technology

Tempered glass stemalite is made only in industrial conditions, using specialized equipment:

- slat conveyor;

- chambers for applying enamel suspension to the surface;

- dryer;

- kilns for firing colored sheets.

Ordinary glass is used as a raw material (vertical alignment, rolled raw, patterned or polished). The technological process for the production of stemalite includesseveral basic steps:

- Cutting. Transparent sheets of ordinary glass are placed on a mechanical table equipped with adjustable cutting heads and cut into pieces of the required size. The edges of the sheets must be processed with grinding wheels - this reduces the risk of damage to the material during heat treatment.

- Cleaning. Before applying the enamel, it is important to properly prepare the surface of the glass. The sheets are placed in a washer-dryer, where they are sprayed on both sides with warm water and degreasers, and then treated with soft brushes.

- Coating. First of all, an enamel suspension is prepared for staining stemalite. What it is? A thinner is added to dry powdered paint or paste (it can be ordinary water or special organic solvents). Then the liquid mixture enters the spraying machine, which, using a system of nozzles, evenly sprays the enamel on the glass.

- Tempering in a furnace. Immediately after that, the sheets are removed from the conveyor and sent to the oven, where they are heated to 650-700°C. The temperature level depends on the refractoriness of a particular type of enamel.

- Cold air treatment. The heated glass is fixed on the blowing grate and installed in front of the fan in a vertical position, due to which the sheets are cooled evenly.

Sometimes silk-screen printing (painting through a mesh) is used instead of the traditional method of applying enamel. In this case, glass sheets are placed in a special frame, which is a kind of"pattern" covering those areas that should not get paint.

Technical capabilities

Modern equipment allows the production of many types of enameled glass with different characteristics:

- sheet sizes - from 200x250 to 1260x3000 mm;

- stemalite thickness - 3-25 mm;

- application of enamel - continuous or sparse layer;

- color - more than 120 shades according to the RAL table.

The light transmission of the material is determined by the amount of paint: the thinner the layer, the higher the transparency. To give a sheet of stemalite texture, the desired pattern is applied to fresh, not yet hardened enamel.

Advantages and differences from ordinary glass

What is stemalite? This is a building material that combines the decorative properties of ordinary glass, but at the same time has much higher strength and resistance to the external environment.

- The sheet is able to withstand temperatures up to 700°C. The density of the sheet reaches 2500 kg/m3, and the bending strength is about 25 kgf/mm2, which is 5 times higher than that of plain glass.

- The material is resistant to acid and alkaline environments, normally tolerates high humidity and steam.

- Due to the durable enamel, the surface of stemalite is almost impossible to damage or scratch.

At the same time, tempered glass is very durable and virtually maintenance-free. importantthe point is also that the enamel coating does not contain toxic components and fully complies with environmental standards.

Application areas

Due to its attractive appearance and excellent performance, painted glass is widely used in construction and interior design.

- Facade glazing. The use of double-glazed windows with stemalite allows you to aesthetically hide the load-bearing structural elements and bring to life non-standard architectural ideas.

- Wall cladding. Knowing what it is - stemalite, you understand: it is not surprising that this material is so popular in the decoration of industrial and commercial premises. The tempered glass cladding is easy to clean from any contamination, and is not afraid of being treated with disinfectants.

- Production of doors. Compared to ordinary glass inserts, a glass unit with stemalite looks much more impressive, and the likelihood that someone will accidentally break it is almost zero.

- Creation of office and room partitions. A variety of shades and textures allows you to choose the best option for any interior.

- Production of advertising and commercial equipment (showcases, racks, etc.).

- Arrangement of glass floors, stairs and other decorative elements.

- Furniture production.

The only significant disadvantage of stemalite is its high cost. In many ways, it depends on the technical characteristics of a particular sheet, however, the price of 1m2 rarely falls below 2000-2500 rubles

Features of operation

Despite the high strength of stemalite, double-glazed windows made of this material require compliance with certain rules. So, in order not to damage the enamel, it is not recommended to use abrasive cleaners, hard metal brushes and rough paper to wash painted glass. Instead, it is advisable to use soft, wet, short-haired wipes.

Please note that finished stemalite sheets cannot be drilled or cut. Any technological holes, edges and chamfers are cut directly during production.

Recommended:

How to make glass? Glass production technology. glass products

Glass is familiar to everyone. But the process of making it is extremely exciting. Each stage is important and affects the quality of the final product. The basis is sand, soda, lime. The process is almost entirely automated. Surprisingly, glass can even be made at home

The difference between ordinary shares and preferred shares: types, comparative characteristics

In the article we will consider what is the difference between ordinary shares and preferred shares. The latter are a financial instrument that is between ordinary shares and bonds. And if dividends are paid regularly, then such elements are somewhat reminiscent of paper with a variable coupon. And when they are not paid, they can be equated to ordinary shares

Glass sandblasting: glass processing description, equipment, application, photo

Among the numerous variations of interior decoration, sandblasting of a glass or mirror surface occupies a special place. This technology involves exposing the canvas to sand or other abrasive with a jet of compressed air released under high pressure. As a result, the surface changes and becomes matte, rough, velvety or painted with patterns. In the article we will consider what is sandblasting glass

Grinding car glass. How to grind glass

The article is devoted to glass grinding. The grinding procedure, its tasks, technique, materials, etc. are considered

Glass factories in Russia. glass industry

The glass industry occupies an important place in the country's economy. Glass factories in Russia operate in almost every region. Window panes and portholes, bottles and dishes, household and interior items - without these items it is impossible to imagine modern civilization