2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:45

For a long time in joinery and carpentry, a tongue-and-groove connection has been used. Ancient architects, using this method, managed to create unique wooden buildings without a single nail or screw. And although a wide variety of hardware is now quite accessible, the articulation of individual parts of various structures by this method has not only not lost its relevance, but is also widely used in modern products and materials.

The principle of connection and its varieties

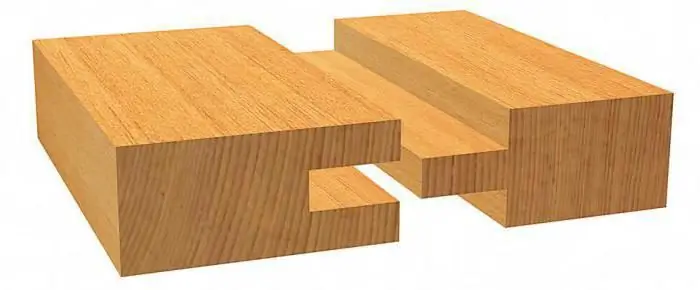

According to the design, all spike-groove joints are made according to the same principle: a protrusion is made on one part, and a recess on the second. In terms of configuration and size, they are exactly the same. With a tight articulation of these two parts, a strong technological unit is obtained. During the construction of houses, such a connection prevents the shift of one part of the structure relative to the other; in the manufacture of furniture, it significantly increases the area to which the adhesive is applied, thereby providing additional strength to the product.

According to the geometric shape of the protrusion and recess, such joints are divided into two main types:

rectangular section (sometimes with rounded edges of spikes and grooves);

in the form of a trapezoid (still hercalled "dovetail"

According to the number of spikes and recesses that need to be made for one articulation of parts, these joints are divided into:

- single spike;

- multi-thorn.

Important! Regardless of the number and geometric shape of the protrusions and recesses, they must be made only parallel to the wood fibers.

Scope of application

The thorn-groove connection has found application in many areas of our daily life. For example, when arranging the floors of rooms according to this principle, such familiar coatings as laminate, parquet, parquet board, ordinary floorboard, chipboard, fiberboard or MDF boards are joined.

Wood, as one of the most environmentally friendly materials, is used to make a wide variety of furniture (from a simple kitchen stool to a designer set for a living room or dining room), roller blinds, blinds and much more. And all these products are mainly made using a tongue-and-groove connection.

When building wooden frame buildings, houses from timber, when arranging the beam-rafter structure of the ceiling and roof, one cannot do without arranging ledges and recesses.

Beam connection

Thorn - a groove in the connection of the beam is used both for arranging corner structures made of wood, and for longitudinal alignment of individual pieces. Depending on the dimensions of the section and the expected loads, the geometry and number of protrusions andeyes. For example, in the construction of wooden houses, one-stud connection is mainly used. And to increase the length of small-section bars using glue, a multi-thorn method is used.

Connecting boards

Almost all owners of suburban real estate have long been fond of such material as lining, as a result of which they get an absolutely flat vertical surface. A spike-groove connection of boards is used for arranging floors, interior decoration of a house, as well as for external cladding of a building (naturally with an antiseptic coating).

The protrusions are tightly fixed in the recesses of adjacent boards, which prevents them from moving relative to each other. When arranging the floors, the tight connection of the grooved boards between themselves prevents their displacement in the vertical plane (the floor turns out to be even) and significantly increases the heat-saving properties of the coating (there are simply no gaps between the boards).

Using a manual electric router

Arrangement of tenon-groove joints with a milling cutter minimizes labor costs and significantly reduces the time for carpentry work. Of course, this useful tool will not help when building a house, for example, from a bar with a section of 150 x 150 mm, since there are no cutters of this size for a manual router, and the power of this unit will not be enough to install them. But if you want to build furniture yourself, small window frames or door frames, then thistool is essential. Depending on the size of the parts to be joined and the geometric configuration of the connection, you get the desired cutter, or maybe two (one for cutting a groove, the other for making a spike). Milling tool adjusters, as well as guide bearings (usually included with these router bits), will help you create ridges and grooves that match exactly in size and shape.

DIY tools and fixtures

If you need to make some piece of wood product, then it is not economically viable to purchase an expensive electric router. Most likely, everyone in the household will have the necessary set of tools, and if they have to buy in addition, then very little. In addition, additionally purchased devices may later be useful for minor repairs (for example, repairing wooden furniture). In order to make a do-it-yourself thorn-groove connection using only ordinary hand tools, you will need:

- wood saw (with fine teeth);

- carpenter's thickness gauge (special device for marking) or regular construction square;

- ruler and pencil;

- wood chisel.

Self-made corner joint

As an example, consider how to make a spike-groove connection of two bars of the same section under a straightangle with hand tools. Let's say you need to connect 60 x 60 mm bars (they may well be suitable for making window frames for a summer house).

The thickness of the protrusion for a single-tenon connection (in accordance with the recommendations of carpentry handbooks) should be ⅓÷⅜ of the thickness of the bar (in your case it will be 20 mm). The length of the spike will be equal to the thickness of the bar (60 mm). The dimensions of the notch must correspond to the dimensions of the spike, so that it fits into the eyelet with force.

Attention! The spikes must be equipped on the vertical parts of the wooden structure, and the grooves on the horizontal.

The algorithm for performing the work is quite simple:

- First, we mark the future protrusions and lugs. If you treat this process without due attention, then the spikes and grooves made may not match each other in size or relative position. There is also a danger that they will not fit tightly into each other. All this will significantly reduce the strength and reliability of the connection.

- Using a thicknesser (or square) at a distance of 60 mm from the end, draw a line on all four sides of both bars.

- Then, on two opposite sides and on the end, draw two parallel lines at a distance of 20 mm from each other.

Along the marking lines with a hacksaw, we cut the end to the transverse line, that is, to a depth of 60 mm

Note! So that the thickness of the cut (approximately equal to the setting of the teeth of the cutting blade of the hacksaw) does not affectthe accuracy of the connection, we install the saw blade from the outside (when arranging a spike) or from the inside (when making a groove).

- At the end of the bar with a ledge, saw off the outer pieces of wood.

- With a chisel, carefully hollow out the inside of the recess.

Insert the spike into the groove and check the connection made. If necessary, remove protruding defects with a chisel

In closing

If you need to equip your own tenon - groove connection of wooden parts, it is best to practice on scraps of bars.

If the protrusions and recesses made exactly matched, and the articulation of the individual parts turned out to be strong, then you can start working on the prepared building material. Well, if the spike enters the groove too freely, or vice versa, then you need to check the markings again, conduct another workout, and only after that proceed with the implementation of the planned project.

Recommended:

Self-locking nuts - a secure connection without Grover washers and locknuts

For connections that do not experience significant mechanical loads during operation, self-locking nuts stamped from sheet steel can be used, creating increased resistance during reverse motion due to the springy properties of the material of manufacture

How to make money without money? Ways to make money. How to earn real money in the game

Today everyone can make good money. To do this, you need to have free time, desire, and also a little patience, because not everything will work out the first time. Many are interested in the question: "How to make money without money?" It's a perfectly natural desire. After all, not everyone wants to invest their money, if any, in, say, the Internet. This is a risk, and quite a big one. Let's deal with this issue and consider the main ways to make money online without vlo

How to make money online with reviews? How to make money online as a beginner?

Today there are several popular ways to make money on the Internet: reviews, writing articles, currency speculation and other options. Each of them is interesting and profitable in its own way, therefore, in order to find your place in the network, you will need to try to realize yourself in different directions

How to make money fast in St. Petersburg? Ways to make money fast

Today, the question of how to make money quickly: whether in St. Petersburg, in Moscow, whether in a small provincial town or village - worries a lot of people. And the key word is fast. It seems that people have no other tasks and goals anymore, everyone wants to get rich literally within a matter of days and immediately after that wave to Haiti in order to rest after righteous labors and drown in a sea of pleasures

How to make money on binary options. Find out if you can make money on binary options

Earnings on the Internet are of interest to many today, so we will touch on the topic of how to make money on binary options. Let's take a closer look at the main strategies that are suitable for those who want to try themselves as a trader