2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-06-01 07:12:56

How to chop wood correctly? This question often arises among owners of houses with fireplace or stove heating. At first glance, the task seems very simple, but there are some nuances. This article will provide detailed instructions on how to safely and quickly handle such work.

How to cut?

There are two options for chopping firewood: using modern electrical and mechanical machines or traditional manual way. Let's take a closer look at each option.

Mechanical splitting

Indiscriminate mechanization has reached such an area as chopping firewood. Now on the market there are many units that will help you quickly and at minimal cost to split the log. Modern mechanical tools are highly safe and productive.

Mechanical wood splitters

The specialization of these machines is the splitting of small chocks (up to 50 centimeters). Manufacturers recommend using similar models to owners of woodfireplaces. The mechanical unit does an excellent job of splitting even small logs. The resulting small chocks are used to kindle the fireplace.

The mechanism itself must be installed on a flat surface. To put it into operation, you need to raise the handle and put a log between the cleaver and the stop.

The rocking frame is located below. It is pressed until the workpiece cracks. Similar machines are available on the market in vertical and horizontal models.

Electric and petrol wood splitters

They are able to work offline. How to chop wood in this case? Yes, just put new logs. Moreover, electric machines will cope with cutting better than gasoline ones. For household needs, a small unit with a power of 2-3 kW is enough. Of course, it will cost more than a gasoline wood splitter, as it is more energy efficient and has high performance.

It is also worth paying attention to the stabbing part of the unit. If you need to quickly harvest logs, then it is better to purchase a model that can split a chock into four parts at once. Its cutting part is made in the form of a cross.

Hydraulic splitters

There are three types:

- vertical;

- horizontal;

- mixed.

If you do not know how to properly chop wood with a hydraulic device, then be sure to read the instructions. But one thing is absolutely certain - the efficiency of the unit will depend on the type of model. The household version of this device rotates with a hydraulic pump. Operating a hydraulic wood splitter is much safer than other options. After all, it works from the network and has several degrees of protection at once.

The wood splitter operates due to the gas or liquid that is in the press. The compressed fluid exerts a strong resistance to the moving surface and sets the entire tool to work. Under high pressure, the machine moves towards the workpiece and splits it into several parts (their number depends on the type of blade). Thus, logs can be cut endlessly. All human efforts come down to laying firewood and cleaning the work surface.

Hand splitting. Preparing logs

Ideal firewood for a fireplace and stove has a length of no more than 40-50 centimeters. In addition, short logs will be much easier to chop. Before you start cutting, you need to cut long chocks. The edges should remain even, as then you will have to put firewood on the cut.

Workplace

Chopping logs on the ground is a waste of energy. A hard surface such as asph alt or concrete is avoided as it increases the risk of injury. It is necessary to choose a convenient deck for chopping firewood: wide and approximately 15 centimeters in height. A deck that is too low or too high will create a risk of ricochets.

Equipment

Any real man knows how to chop wood properly and can do it without any protection. And a real man with brains understands perfectly well that bloody callusesnot really fit into his lifestyle. Therefore, he will take care of the necessary equipment in advance. Gloves will protect against blisters and splinters, goggles will protect your eyes, and sturdy boots (ideally steel-toed construction shoes) will protect your fingers and feet from potential exposure to an ax.

Balance

Put the log in the middle of the deck. Moreover, it should be as stable as possible. After all, if a blow with a heavy cleaver slips through and knocks out a badly standing log from the deck, then its flight speed will be impressive.

Smart workflow

It is not enough to know just in theory how to properly chop wood with an axe. It is important to apply this knowledge during the felling process. Do not hit with a cleaver in different places. It is necessary to find the largest crack on the log cut and try to drive the blade at the same angle. It is not necessary to cut in the area of large knots - there is the hardest wood.

Technique

Any person who knows how to properly chop wood with a cleaver puts technique first. After all, efficiency depends on it. And the less useless and energetic movements, the higher it is. No need to do the classic swings behind the head. Grasp the end of the handle with your left hand, and closer to the blade with your right. Slightly bending your knees, raise the ax above your head, straightening your arms. Slide your right palm down, add some muscle strength, gravity will do most of the work for you.

What to consider?

Try not to miss. Otherwise, the heavy ax will continue to move by inertia and twist the wrist. Before starting cutting, you need to take the right position - stand a little away from the log. In this case, if the ax flies past the block, it will not hit the lower limbs. And ask those around you to keep your distance. "Spectators" should not take risks in vain, as during operation the blade itself may break, the handle slip out or fly off from the blow of the chock.

How to properly stack chopped firewood?

You can't place logs directly on the ground. They will absorb moisture from it. Therefore, at first, small in diameter, long and even trellises made of metal pipes or wooden trunks are laid on the soil. The first row of chopped logs is laid so that the ends of the firewood do not lie on the ground, but on the trellises. Well, it is important to raise them at least a few centimeters from the soil surface.

In closing

It remains to tell about one more important point. And it concerns the rules of use and spelling of some words on the topic of this article.

Many people believe that seemingly identical phrases have the same meaning. For example, how to “chop wood” or “chop wood” correctly. In fact, both options are valid, but they have different meanings. In the first case, work is meant with a heavy blunt cleaver, and in the second, with a light and sharp ax.

And what is right: stabbing or stabbing firewood. Here, in terms of spelling rules, is truesecond option. It is a participle formed from the verb of the first conjugation "stab".

Recommended:

Wood processing technology and production of wood products

Wood is an unusual and especially valuable material. For all its familiarity, it has an amazing set of technical and physical properties that a person cannot repeat with the help of synthetic substitutes. This is due to the extensive use of blanks made of natural wood in a variety of industries. Modern wood processing technologies and the production of wood products in general make it possible to provide people with furniture, building materials, decorations, utensils, etc

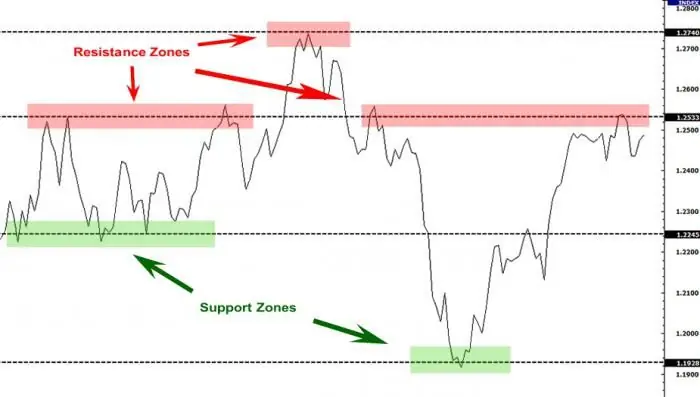

Support and resistance level. How to trade support and resistance levels correctly?

Support and resistance levels are the dominant concepts of the technical analysis of the foreign exchange market. Based on them, a large number of trading strategies have been developed, despite the fact that the lines belong to the category of inaccurate instruments

Collet connections: classification, types of pipes, working technique and instructions for use

The push-in fitting has an external thread with an external hexagon. The nominal passage is 6 mm. The sealing threaded connection is coated. Assembly position can be any. The design works on a reciprocating principle. The operating pressure range varies from 0.95 to 6 bar. Working pressure depending on temperature is equal to the limit from 0.95 to 14 bar

Shaft grinding: technique, necessary materials and tools, step-by-step work instructions and expert advice

Today, shaft grinding is quite widely used in such an industry as mechanical engineering. This operation allows the preparation of parts that will have a small roughness, a slight deviation from the shape, etc

Welding in a shielding gas environment: work technology, process description, execution technique, necessary materials and tools, step-by-step work instructions and expert advice

Welding technologies are used in various branches of human activity. Versatility has made welding in a protective gas environment an integral element of any production. This variety makes it easy to connect metals with a thickness of 1 mm to several centimeters in any position in space. Welding in a protective environment is gradually replacing traditional electrode welding