2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

When it comes to cooling air or water, as a rule, large-scale installations appear before your eyes, familiar from pictures from industrial enterprises of past years. However, progress does not stand still. Today, all this has been replaced by more efficient and compact devices called chillers.

Briefly about the main thing

So, what are industrial chillers and what are they for? It is this information that we will consider in the article. Let's start with a description. As you know, in the domestic sphere, we constantly encounter chillers, and we don’t even know about it. In large offices, laboratories, shopping centers and, of course, in large-scale enterprises, it is unprofitable to install separate air conditioners. This option is quite expensive and, it should be noted, ineffective. When it comes to cooling large areas, industrial chillers are the only choice.

Their task is to reduce the temperature of the air or water. In the interior, they arespecial installations, which are called fan coil units. Externally, the units are similar to classic split-system units. But the principle of operation of this technique is completely different. After all, instead of freon, air or water circulates in the pipes. At the same time, the convenience and comfort of using such systems is at a higher level than that of other modern climate control devices. The uniqueness of the units lies in the fact that they can work both independently and in a common air conditioning system. The principle of operation is to reduce the temperature by absorbing excess heat. The cost of devices and subsequent installation is quite affordable.

Application

Industrial chillers are used where it is necessary to quickly and efficiently cool any media. The installation allows you to do this as efficiently as possible, and with minimal energy consumption. That is why the use of such devices in industry is already practically the first rule of economy. It is worth paying attention to the fact that there are such production processes that require a chilled liquid. For example, in the manufacture of plastics. During their operation, it is very important to observe certain temperature conditions. And it is in such situations that an industrial chiller will help to cool the water.

As a rule, it is installed on ships, mines, poultry farms. Most often, devices are used in the transport, chemical, nuclear, metallurgical and other industries. Due to the fact that the maintenance of chillers is not expensive, this techniqueinstalled in hotels, restaurants, large shopping centers.

Let's talk about the pros and cons

The chiller for industrial refrigeration has a number of advantages. When familiarized with its criteria, each person will be able to understand how effective this installation is. So, let's list some of the advantages of chillers. First of all, it is economy. As we said above, during the operation of the device, energy consumption will be minimal. It is also worth paying attention to the high reliability of the system. If timely maintenance is carried out, then such an installation is able to work without breakdowns for quite a long time. Compactness and high functionality are the main advantages of chillers. But with all the advantages, there is one significant drawback in devices of this type - the lack of mobility.

Characteristic

In terms of their parameters, industrial chillers surpass even the split systems common today, as they have better characteristics at all stages of installation and operation. This device is a device consisting of a pump and a tank where the cooler is located directly. All chillers are equipped with temperature sensors. Devices are controlled by programs. No ongoing monitoring required.

The main installation is usually located on the roof of the building. Therefore, security is at a high level. For wiring, ordinary pipes and fittings are used. Such a decision makeschillers are much more advantageous when installed. Thanks to its high power, even a very spacious room or house can be served by one chiller.

Repair Highlights

One of the most important issues for companies and individuals who operate devices is repair. Like any other similar equipment, chillers also need to be serviced. However, unlike air conditioners and split systems, this technique is much more complex. Therefore, an ordinary master may not be able to handle it.

Industrial chillers are usually repaired on site. And the reason is that it is sometimes simply impossible to dismantle the entire installation. Especially if we are talking about a large building, where the cooler is located on the roof. Specialists come to the place and carry out technical diagnostics. After that, repairs begin, and the necessary parts are delivered to the place of work.

Chiller Service

When purchasing a similar device for your home or office, make sure that it always works for you with maximum efficiency. It is very simple to do this - you need to agree on the service of such a system. After all, it is much better to check all the nodes with a certain frequency than to carry out large-scale repairs later. Chiller service includes checking the system sections (cooler, pumps, communications) and maintaining the entire installation in the highest quality condition. By doing this on a regular basis, youyou can be sure that in any situation the temperature regime will not be violated.

Recommended:

Air conditioning system maintenance: choosing a company, concluding a contract, rules for registration, act of work performed, maintenance instructions, regulations and safe work

The main task of the ventilation system is to provide access and exhaust air, as well as its filtration and temperature control. In order for these tasks to be fully completed, it is necessary to install special equipment, as well as equip the blower system. Maintenance of the air conditioning and ventilation system is mandatory for both civil and industrial facilities

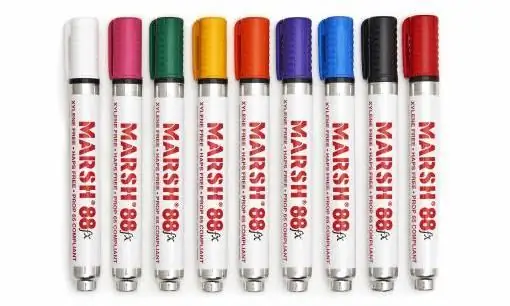

Industrial marker: description, composition, rules, application and purpose

Industrial marker - a writing tool for applying information on a variety of surfaces. In this case, the surface can be wood, glass, stone, metal, leather, painted materials and even rust. The requirements for such a marker are very specific

Workplace maintenance: organization and maintenance of the workplace

An important part of the process of organizing labor in production is the organization of the workplace. Performance depends on the correctness of this process. An employee of the company should not be distracted in his activities from the fulfillment of the tasks assigned to him. To do this, it is necessary to pay due attention to the organization of his workplace. This will be discussed further

Industrial boilers: description, types, functions. Industrial expertise of boilers

The article is devoted to industrial boilers. The varieties of such units, functions and nuances of the examination for the safety of equipment are considered

Industrial safety of hazardous industrial facilities: rules and requirements

In modern production, unfortunately, there are accidents. However, there are special instructions, the observance of which helps to prevent disasters. Consider further the basic rules of industrial safety