2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:47

Production of water directly from a well is the optimal solution to the problem of water supply in a private household. But if you plan to use the pumped liquid for drinking, then you cannot do without special cleaning. For this, downhole filters are used in different designs. The choice will depend both on the characteristics of the water source itself and on the requirements for the composition of the liquid.

What is filtering for?

There are many threats posed by untreated water from an ordinary well. The main dangers include high concentrations of iron, s alt, manganese and nitrates. This will be evidenced by both an unpleasant smell and a specific taste. The presence of foreign mechanical impurities is undesirable both for the body and for equipment that uses water. Therefore, in any case, a downhole sand filter with coarse cleaning should be provided. These are standard membrane devices that can beintegrate into the design of pumping equipment. More sophisticated systems should be used if signs of bacteriological contamination are found.

If groundwater somehow interacts with fertilizer residues and household waste leaving through the sewer, then with a high probability there will be giardia, coliphages, and coliform microorganisms in the well.

Features of the borehole water treatment device

It is mandatory for cleaning systems to include a filter element with filler or replaceable fibers that trap unwanted particles and trace elements. This structural nuance makes borehole systems related to other means of water treatment. But in terms of technical performance, the very principle of organizing cleaning has significant differences. Firstly, most designs are designed for installation in the circuit between the well itself and the pump. Accordingly, a frame, an installation base and shut-off control equipment are provided.

For the borehole filter, a special loading module is provided, through which the pumped water also passes. Secondly, many devices have sludge separators and other containers for cutting off and collecting retained elements. The most advanced designs provide for the possibility of automatic disinfection of the collected material with subsequent shipment to the septic tank.

Reverse osmosis filters

This system is defaultconsidered to be an effective regulator of water for its hardness. That is, the filter corrects the oxidation indicators, including due to the withdrawal of potassium and magnesium elements. But recently, reverse osmosis membranes have received additional functions, which are expressed in a decrease in iron levels and a delay in pollution at the molecular level. Membrane downhole reverse osmosis filters are also capable of removing particles dissolved by ionic and chemical treatment systems. The difficulty of using this type of equipment lies only in the fact that it requires a separate place for installation. Typically, reverse osmosis structures are located next to the pumps in an enclosed area.

Slot filtration

The system is a single or group installation of several filters in the form of pipes. The design is designed to prevent the passage of coarse-grained elements with a size of 2-10 mm. There are precisely slotted and perforated models with different configurations of slots and holes on the surface. The device is installed in the well and serves as a basic barrier against mechanical unwanted elements before water reaches the pump. But when choosing a slotted downhole filter, it must be borne in mind that the desire for deep cleaning at this stage due to the narrowing of the holes can result in blockage and rupture of the pipe. Strengthening the structure or using impractical stainless steel analogues will also not lead to anything good, since in conditions of a high well flow rate, productivity will be significantly reduced.

Pump Filters

Special filters exist for well pumps. In this context, they should be considered as deep. The basis of such a filter contains a group of membranes (several degrees of purification) and a sealing element for separating the receiving channel for clean water from the channel directed to the sump. The seal is usually made in the form of a bell. It is attached to the supporting body on a hinged snap with a cuff.

Since the design of the depth filter combines the principles of fine and coarse cleaning, special measures are also provided to protect the device from overloads. The simplest way of such protection involves regular automatic cleaning of the well filter by flushing the accumulated sediments to the outlet. This will require a separate water supply circuit, but again, it can be set to work only during certain periods of critical blockage, as evidenced by the increase in pressure in the circuit. Such functionality can be easily implemented on the basis of a modern pumping station.

Casing Filters

Specially for the design of a borehole funnel, filter manufacturers produce combined metal-plastic installations with diameters of 100-150 mm. These are perforated casing filters with wire windings and an outer casing based on a durable fabric, usually made of fibrous-porous polyethylene.

A distinctive feature of these devices is the possibility of universal use inalkaline, acidic and neutral soil environments, even with high mineralization. During operation, the downhole filter for casing pipes made of fibrous-porous polyethylene does not affect the organoleptic qualities of the serviced water, does not emit chemical elements and does not become overgrown with s alt substances. For severe service conditions with high pressure, it is also recommended to use filters with a special weave metal mesh. The device protects the water supply circuit from both sand inclusions and small elements with a fraction of 0.1-0.25 mm.

Gravel Screens

The design of the gravel cleaning devices for the well protects the channel from the passage of small rock particles up to 2.5 mm in diameter. The frame is made using the same technique as the previous fixtures. Outside, a metal mesh is used for borehole filters, which is twisted with wire and, if necessary, put on another protective cylinder made of lightweight plastic. The peculiarity of this design is the use of gravel as a natural filler.

In finer cleaning systems, this function is performed by activated carbon and other specialized sorbents, but in this configuration, gravel filler with fine grains of sand is sufficient for surface mechanical cleaning.

Features of titanium filters

As the final stage of mechanical cleaning, well filter manufacturers offer titanium devices. According to the developers, such devices are capable ofretain elements down to 0.8 microns, while softening and iron-free water. Titanium itself is used as a durable filler, also providing an antiseptic effect. Although there are ambiguous opinions regarding the harmlessness of this material as such, there are practically no complaints about its work and harmful effects. On the other hand, the strength qualities of downhole filters of this type, their functionality and ergonomics of use are noted.

Reviews about manufacturers of filtration systems

Development and production of downhole equipment and filters are mainly carried out by industrial enterprises. Users of these products especially highlight models from Samara-Aviagaz, Fibos and Spetsmash. As for the Samara-Aviagaz enterprise, its assortment includes inexpensive, but reliable FS downhole filters for casing pipes that prevent sand drift. According to users, such structures also perform a structural and protective function, preventing the collapse of the rock.

The Fibos company focuses on fine filters. The owners of mesh filters of this brand also point to the positive effect of water softening, and a thin filtration membrane traps particles up to 1 micron.

Spetsmash products are recommended for water purification on an industrial scale. The frameless slot design is being developed to be integrated into wells of any configuration, which expands the scope of such filters. But the cost of this productconsiderable, which is explained by the possibility of individual development of the project.

How to make a well filter with your own hands?

The easiest way to make a filtration is to use a ready-made perforated pipe like a slotted plastic membrane for this purpose. Its channel with holes on the surfaces will screen out large particles that will be retained and sent to the sump. This will allow for coarse pre-cleaning before finer filtration steps. Suitable for both metal and plastic pipes. The main thing is to ensure the correct perforation. For this, holes with a diameter of 10-15 mm are formed. Their total surface area should be about 15% of the total product area.

Next, the segment must be wrapped in a membrane sheet. Usually, a plastic mesh with cells of the order of 5 mm is used for such purposes. Next, the downhole filter pipe is introduced into the water intake infrastructure at the primary level. It can be fixed with special holders from the casing and, if necessary, bring the elements of the locking regulation.

Conclusion

A filtration system for water from a well is one of the basic conditions for the arrangement of a water supply facility. Requirements for liquid purification increase if it is planned to use it for domestic needs, but technical requirements also impose serious requirements on the composition of water. At a minimum, in this case, a well pump filter should be used to keep the equipment from clogging with sand and slurry. If the matterAs for the supply of a private house with a full consumer spectrum, it is desirable to organize multi-stage water treatment with separate stages of mechanical and biological treatment. The technological chain will run from the well itself to the pump and water intake equipment.

Recommended:

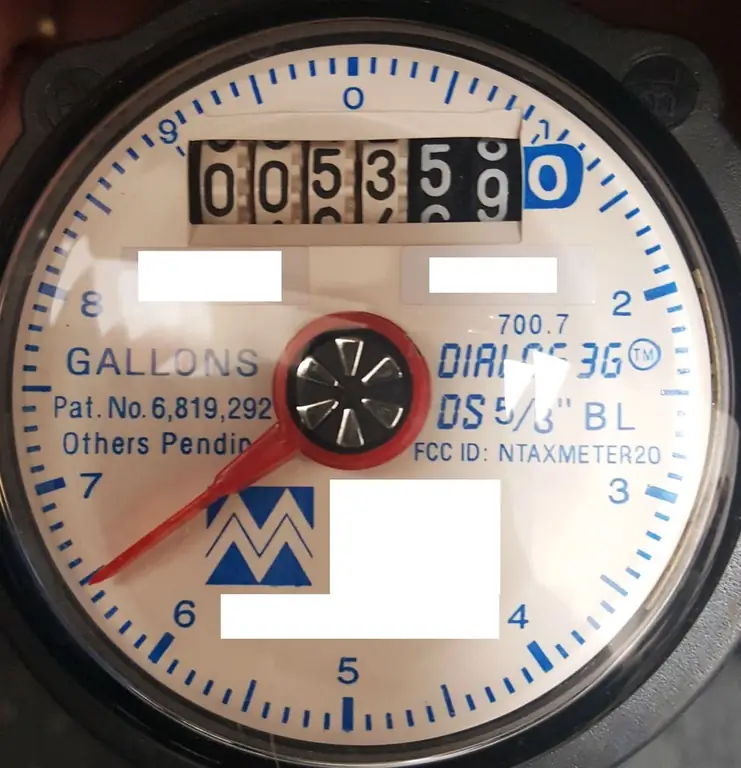

Shelf life of water meters: period of service and operation, verification periods, operating rules and time of use of hot and cold water meters

The shelf life of water meters varies. It depends on its quality, the condition of the pipes, the connection to cold or hot water, the manufacturer. On average, manufacturers claim about 8-10 years of operation of devices. In this case, the owner is obliged to carry out their verification within the time limits established by law. We will tell you more about this and some other points in the article

"Royal Water": customer and employee reviews, addresses, order conditions, delivery and water quality

Royal Water is one of the largest companies in the bottled water market. The company was founded in 1994. An extensive dealer network and a large number of branches determined the presence of the organization in many regions of the country

Recycled water supply - definition, scheme and features. Recycled water supply system

Recycling water supply is created for the purpose of ecological protection of the environment, economy, and also in case of emergency caused by the creation of a small enterprise. Profitability is determined by design calculations. In the future, it will only increase due to the increase in the cost of water and the growth of fines for environmental pollution

High pressure pumps for water: types, features and reviews

Today, one cannot do without water in any sphere of human life. But central water supply is not available in every holiday village and the private sector. Even if such a system is present, in summer it is not always possible to use water intake points, since there is simply not enough pressure. But the water pump solves this problem

The balance of water consumption and sanitation is a necessary calculation in the design of any facilities and in water use

One of the documents required by an economic entity when issuing a license for the use of a surface water body or when issuing a license for the extraction of groundwater is the balance of water consumption and water disposal. This water management calculation is also mandatory when designing any object of the national economy or a residential building