2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:26

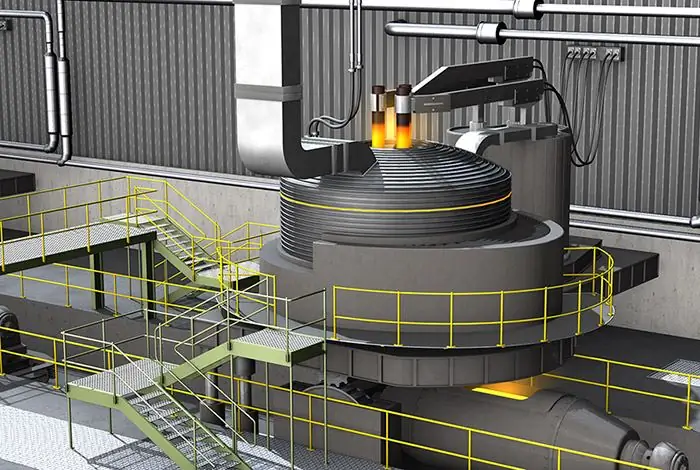

A steel arc furnace (EAF) is a device that heats material by electrical bending.

Industrial appliances range in size from small units, roughly one ton of power (used in foundries to make cast iron products) to 400 units per ton, used for steel recycling. Arc steel furnaces, EAF, used in research laboratories may have a capacity of only a few tens of grams. The temperature of industrial devices can reach 1800 °C (3272 °F), while laboratory installations exceed 3000 °C (5432 °F).

Arc steel furnaces (EAFs) differ from induction furnaces in that the material being loaded is directly subjected to electrical bending, and the current at the terminals passes through the charged material.

Construction

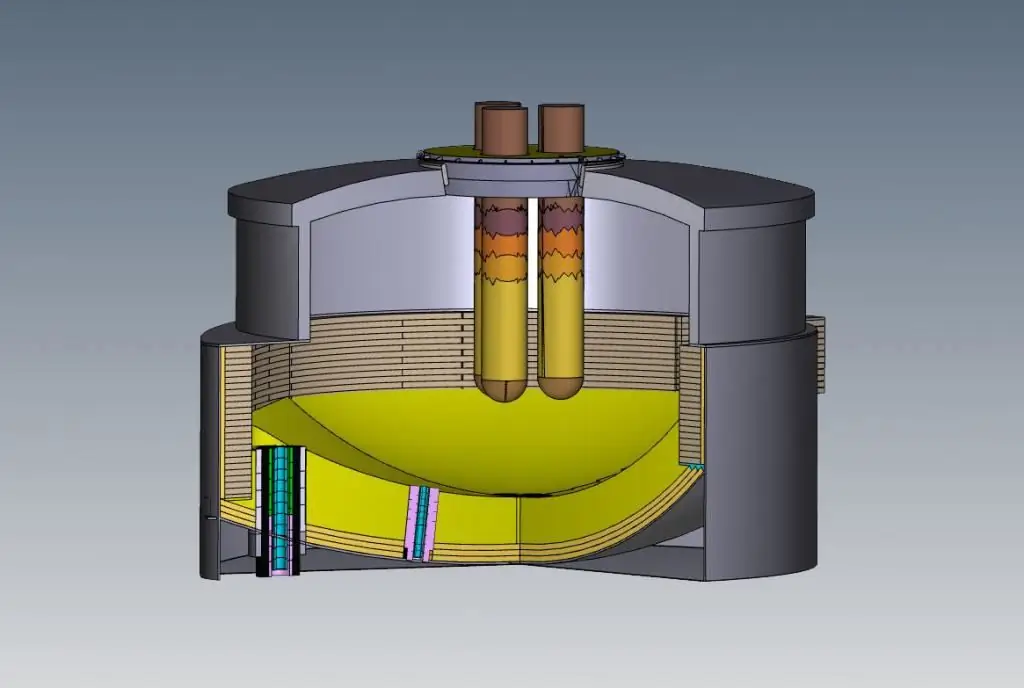

Arc steel furnace is used for steel production and is composed of a refractory vessel. Mainly divided into three sections:

- Shell, which consists of side walls and bottom steelbowls.

- Pallet which is made of refractory material.

- Roof. It can be with a heat-resistant lining or water-cooled. And it is also made in the form of a ball or a truncated cone (conical section). The roof also supports a refractory delta at its center through which one or more graphite electrodes enter.

Individual items

The hearth may have a hemispherical shape and is needed in an eccentric furnace for tapping the bottom. In modern workshops, the arc steel furnace - EAF 5 - is often elevated above the ground floor so that ladles and slag pots can be easily maneuvered under either end. Separate from the structure is the electrode support and electrical system, as well as the inclined platform on which the instrument stands.

Unique tool

A typical EAF 3 steel-smelting arc furnace is powered by a three-phase source and therefore has three electrodes. They have a round section and, as a rule, segments with threaded connections, so that as they wear, new elements can be added.

The arc is formed between the charged material and the electrode. The charge is heated both by the current passing through it and by the radiated energy released by the wave. The temperature reaches about 3000 °C (5000 °F), causing the lower sections of the electrodes to glow like incandescent lamps when the arc furnace is operating.

The elements are automatically raised and lowered by the positioning system, which can use any electricwinch, hoists or hydraulic cylinders. The regulation maintains an approximately constant current. What is the power consumption of an arc furnace? It is kept constant during charge melting, even though the scrap may move under the electrodes as it melts. The mast sleeves holding the element can either carry heavy busbars (which can be water-cooled hollow copper tubes supplying current to the clamps) or "hot sleeves" where the entire top carries the charge, increasing efficiency.

The latter type can be made of copper plated steel or aluminum. Large water-cooled cables connect busbars or brackets to a transformer located next to the oven. A similar tool is installed in storage and cooled with water.

Tapping and other operations

The EAF 50 steel arc furnace is built on an inclined platform so that liquid steel can be poured into another container for transportation. The tilting operation to transfer molten steel is called tapping. Initially, all steel-making vaults of the arc furnace had a discharge chute covered with refractory, which was washed out when it was tilted.

But often modern equipment has an eccentric bottom outlet valve (EBT) to reduce the incorporation of nitrogen and slag into the liquid steel. These ovens have an opening that runs vertically through the hearth and shell and is off-center in a narrow egg-shaped "spout". It's filledrefractory sand.

Modern plants may have two shells with one set of electrodes that are passed between them. The first part heats the scrap, while the other is used for melting. Other DC ovens have a similar layout but have electrodes for each sheath and one set of electronics.

Oxygen elements

AC furnaces usually have a pattern of hot and cold spots along the perimeter of the hearth, located between the electrodes. In modern ones, oxy-fuel burners are installed in the side wall. They are used to supply chemical energy to minus zones, which makes the heating of steel more uniform. Additional power is provided by supplying oxygen and carbon to the furnace. Historically this was done with spears (mild steel hollow tubes) in the slag door, now it is mostly done with wall mounted injection units that combine oxy-fuel burners and air supply systems into one vessel.

A modern medium-sized steel furnace has a transformer rated at about 60,000,000 volt-amps (60 MVA), with a secondary voltage of 400 to 900 and a current in excess of 44,000. In a modern shop, such a furnace is expected to produce 80 metric tons of liquid steel in about 50 minutes from cold scrap loading to tapping.

In comparison, basic oxygen furnaces can have a capacity of 150-300 tons per batch or "heat up" and generate heat for 30-40 minutes. There are huge differences in the details of furnace design and operation,depending on the final product and local conditions, as well as ongoing research to improve plant efficiency.

The largest scrap-only (in terms of tap weight and transformer rating) is a DC device exported from Japan with a tap weight of 420 metric tons and fed by eight 32 MVA transformers for a total power of 256 MBA.

It takes approximately 400 kilowatt-hours to produce a ton of steel in an electric arc furnace, or about 440 kWh per metric. The theoretical minimum energy required to melt scrap steel is 300 kWh (melting point 1520 °C / 2768 °F). Therefore, a 300-ton EAF with a power of 300 MVA will require about 132 MWh of energy, and the turn-on time is approximately 37 minutes.

Steel production using an electric arc is only economically viable if there is enough electricity with a well-developed network. In many places mills operate during off-peak hours when utilities have excess production capacity and the price per meter is lower.

Operation

The arc steel furnace pours steel into a small ladle machine. Scrap metal is delivered to a recess located next to the smelter. Scrap tends to come in two main varieties: scrap (white goods, cars and other items made from similarlight steel) and heavy melt (large slabs and beams), as well as some direct reduced iron (DRI) or pig iron for chemical balance. Separate furnaces melt almost 100% DRI.

Next step

Scrap is loaded into large buckets called baskets with clamshell doors for the base. Care must be taken to ensure that the scrap is in the basket to ensure good operation of the furnace. A strong melt is laid on top with a light layer of a protective shred, on top of which another part lies. All of them must be present in the oven after loading. At this time, the basket can move into the scrap preheater, which uses the hot, off-gases of the smelter to recover energy, improving efficiency.

Overflow

Then the vessel is taken to the smelting shop, the roof of the furnace is opened and the material is loaded into it. Transferring is one of the most dangerous operations for operators. A lot of potential energy is released by tons of falling metal. Any liquid matter in the furnace is often pushed up and out by solid scrap and grease. Dust on metal ignites if the oven is hot, causing a fireball to erupt.

In some double-shell devices, scrap is loaded into the second while the first is melting, and is preheated by the exhaust gas from the active part. Other operations are: continuous loading and working with temperature on a conveyor belt, which then unloads the metal into the furnace itself. Other devices can boothot substance from other operations.

Voltage

After charging, the roof leans back over the furnace and melting begins. The electrodes are lowered onto the scrap metal, an arc is created, and then they are set so that they spread in the crumb layer at the top of the device. Low voltages are selected for this operation to protect the roof and walls from excessive heat and arc damage.

Once the electrodes have reached the heavy melt at the base of the furnace and the waves are shielded by the crowbar, the voltage can be increased and the electrodes raised slightly, lengthening and increasing the power for the melt. This allows the molten pool to form more quickly, reducing tap-off time.

Oxygen is blown into scrap metal, burning or cutting steel, and additional chemical heat is provided by wall burners. Both processes accelerate the melting of the substance. Supersonic nozzles allow oxygen jets to penetrate the foaming slag and reach the liquid bath.

Oxidation of impurities

An important part of steelmaking is the formation of slag that floats on the surface of the molten steel. It is usually composed of metal oxides and also acts as a place to collect oxidized impurities, as a thermal blanket (stopping excessive heat loss) and also helps to reduce erosion of the refractory lining.

For a furnace with basic refractories producing carbon steel, the common slag formers are calcium oxide (CaO in the form of calcinedlime) and magnesium (MgO in the form of dolomite and magnesite.). These substances are either loaded with scrap or blown into the furnace during meltdown.

Another important component is iron oxide, formed when steel is burned with oxygen introduced. Later, when heated, carbon (in the form of coal) is injected into this layer, reacting with iron oxide to form metal and carbon monoxide. This results in foaming of the slag, resulting in greater thermal efficiency. The coating prevents damage to the roof and side walls of the oven from radiant heat.

Combustion of impurities

Once the scrap metal is completely melted and a flat pool is reached, another bucket can be loaded into the furnace. After the second charge is completely melted, refining operations are carried out to check and correct the chemical composition of the steel and superheat the melt above its freezing point in preparation for tapping. More slag formers are introduced and a lot of oxygen enters the bath, burning impurities such as silicon, sulfur, phosphorus, aluminum, manganese and calcium, and removing their oxides into slag.

Carbon removal occurs after these elements burn out first, as they are more similar to oxygen. Metals that have a lower affinity than iron, such as nickel and copper, cannot be removed by oxidation and must only be controlled through chemistry. These are, for example, the introduction of direct reduced iron and cast iron mentioned earlier.

Foamy slagpersists throughout and often overflows the oven to overflow from the door into the intended pit. Temperature measurement and chemical selection are carried out using automatic spears. Oxygen and carbon can be measured mechanically with special probes that are immersed in steel.

Production Benefits

Using a control system for steel-smelting arc furnaces makes it possible to produce steel from 100% raw materials - scrap metal. This greatly reduces the energy required to produce the substance, compared to primary production from ores.

Another benefit is flexibility: while blast furnaces can't vary significantly and can run for years, this one can be started and shut down quickly. This allows the steel mill to vary production based on demand.

Typical arc steel furnace is the source of steel for mini mill, which can produce bar or strip product. Mini-smelters can be located relatively close to steel markets and transport requirements are less than for an integrated plant, which is usually located close to shore for shipping access.

Arc Steel Furnace Device

The schematic cross section is an electrode that is raised and lowered by a rack and pinion drive. The surface is lined with refractory bricks and bottom cladding. The door allows access to the interiorparts of the device. The oven body rests on rocker arms so that it can be tilted for tapping.

Recommended:

Food stainless steel: GOST. How to identify food grade stainless steel? What is the difference between food stainless steel and technical stainless steel?

The article talks about grades of food grade stainless steel. Read how to distinguish food stainless steel from technical

Diamond boring machine: types, device, operating principle and operating conditions

The combination of a complex cutting direction configuration and solid-state working equipment allows diamond boring equipment to perform extremely delicate and critical metalworking operations. Such units are trusted with the operations of creating shaped surfaces, hole correction, dressing of ends, etc. At the same time, the diamond boring machine is universal in terms of application possibilities in various fields. It is used not only in specialized industries, but also in private workshops

Delayed coking unit: project, operating principle, power calculation and raw materials

Delayed coking unit: principle of operation, raw materials and finished products. Description of different types of equipment. Schematic diagram of a two-block plant, main technological parameters. Design sequence and power calculation

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities

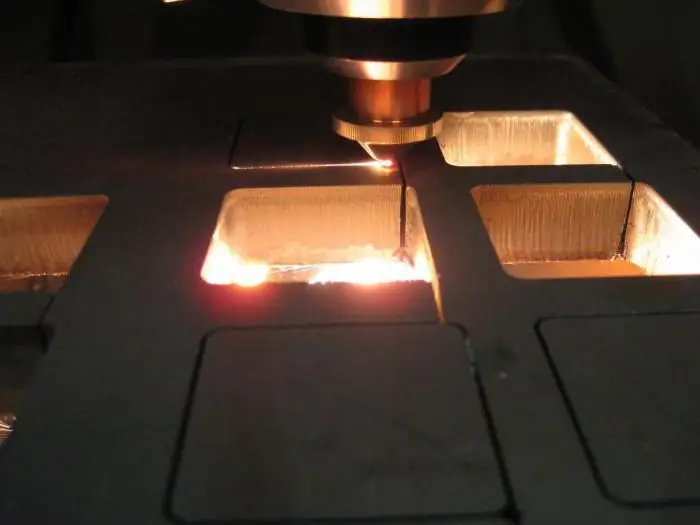

Ytterbium fiber laser: device, principle of operation, power, production, application

Fiber lasers are compact and rugged, point precisely and dissipate thermal energy easily. They come in many forms and, having much in common with other types of optical quantum generators, have their own unique advantages