2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

The word "shavings" is the most common concept for the Russian language. But the types of chips in the understanding of people are different. Some even ascribe edifying meaning to the shavings. After all, they say about a strict boss that he removes shavings from his subordinates. At the same time, they mean that he reprimands employees for wrong actions, improper attitude to work, trying to eradicate vicious practices.

Something similar happens in the manufacture of parts: an extra layer is removed from the workpiece, obtaining the necessary product. And shavings, she is shavings - the usual industrial waste. It is collected and sent for recycling.

What is shavings?

Swarf is a small fraction of any material, including wood, plastic, metal, which is a narrow filigree layer removed from the workpiece by means of planing equipment,knives or other tools. In metal production, shavings are a by-product. Her waste is expected. Unnecessary offcuts of non-ferrous, ferrous and even precious metals are formed as a result of machining on drilling, milling and turning machines. As a rule, the chip structure remains identical with the regulated product material. In exceptional cases, a mixture of alloys that differ in chemical composition is found. This is possible after welding, soldering and similar manipulations.

Types of chips

The process of metal cutting (OMP) is carried out under specified parameters using tools and materials with different properties. Depending on this, forces arise in the cutting zone that affect the quality of processing and chip formation. Professor-researcher I. A. Time identified the following main types of chips:

- fracture chips - typical in the processing of cast iron, consisting of small fragments-grains;

- drain chips - smooth, curled, most often formed during the processing of copper;

- chips of chipping (cleavage) - fragments of material remaining from the metalworking of hard steels and wins.

By the type and color of the chips, one can judge the quality of the surface obtained as a result of MMP and the manufacturability of the process as a whole.

Turning Parts

The most common method of OMP, which allows you to get a part of the desired configuration and roughness, is turning. essenceconsists in cutting off an unnecessary layer of metal from a blank or blank. Acting on the layer to be removed by the front surface, the cutter deforms it. As a result of metal compression, its compressed element is chipped and dislocated by the front surface of the tool upwards. Then the algorithm repeats: the chips are chipped, separated and curled into beautiful springs.

What types of chips are not found in turning. The following factors influence:

- degree of bonding of metal elements sequentially sheared off during processing (drain chips, breaks and chipping);

- cutting conditions: spindle speed, caliper feed rate, depth of cut;

- application of cutting fluids.

Chip temper color

In mechanical engineering, in particular metal cutting, there is such a thing as tint color. It can be compared, for example, with iridescent stains of gasoline on the surface of a puddle after a heavy rain. It turns out that by the color of the tint and the unusual appearance of the chips, knowledgeable machine operators can easily determine the degree of heating in the cutting zone and understand that something has gone wrong: perhaps the cutter has become dull, which needs to be urgently sharpened or replaced.

The nature of such a phenomenon on the surface of a hot metal is the formation of a thin layer - a film of tint color. What is the degree of incandescence of the chips, such is the color of the film. The color scheme varies fromslightly yellow at 200 0C, bypassing purple and dark blue at 270-290℃, to light gray, almost white at 400 0 S.

Creative chips

Students of engineering educational institutions, who first came to the workshop for practice, admire fresh chips with genuine interest. Snakes, beads, rings, nests - what enthusiastic young people can't see in ordinary shavings.

Different shapes, colors and intricacies of shavings inspire some people to be creative. For example, one of them took a lot of photo frames with beautiful metal shavings and called the unusual gallery “Shavings, you are space!”. Another author, Vladimir Kargin, a lover of creating three-dimensional panels, made a number of paintings made from various types of shavings. All the themes of his paintings are related to nature.

Byproduct of production

Waste of all types of metal shavings, including non-ferrous, is disposed of and sent for recycling. This process is labor-intensive: it includes chip sorting, oil extraction, crushing, briquetting and transportation to the smelter. Briquetting is necessary to minimize waste when remelting chips in furnaces. Chip processing machinery:

- oil extractor centrifuge;

- chip crusher;

- briquetting (baling) presses for compact compaction of chips.

All machine operators know that when cutting metals, you need to protect your eyes and hands: work ingoggles or with protective shields installed on the machines, and remove the wound and stuck chips with a hook. Chips often have a beautiful appearance, but they are always dangerous, because they are: sharp, hot, prickly. Take care of yourself.

Recommended:

Metal band saw. Metal cutting machine

Metal band saw is a high-performance equipment that is responsible for a variety of functions, such as cutting metals and cutting a variety of strong and high-strength materials

Types of metal cutting: an overview of modern technologies and equipment

One of the most common metalworking operations is cutting. It is a technological process during which a sheet or billet is divided into parts of the desired format. Modern types of metal cutting allow this operation to be performed with high accuracy and a minimum amount of scrap

Sheet metal cutting: description, types. metal bending

Today, sheet metal cutting is one of the fairly common technological processes that allows you to get blanks of the desired size and shape. However, there are many methods for performing this procedure and a wide variety of equipment

Cutting mode for milling. Types of cutters, calculation of cutting speed

One of the ways to finish materials is milling. It is used for processing metal and non-metal workpieces. The workflow is controlled by cutting data

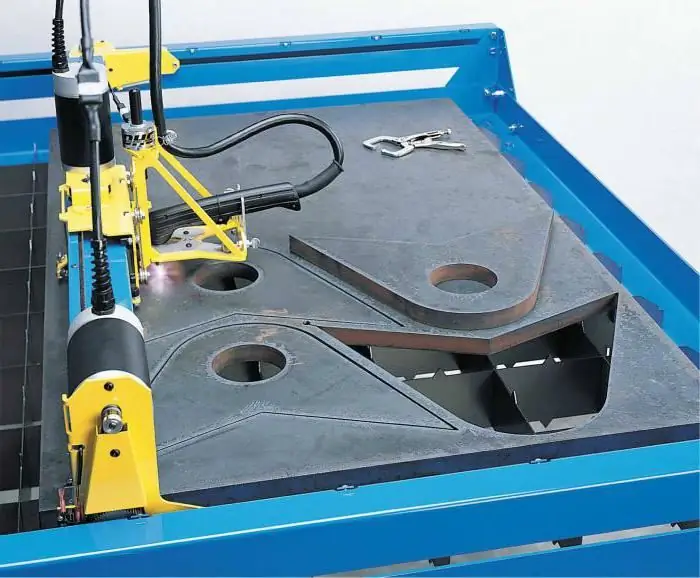

Metal cutting machine. Plasma metal cutting machine

The article is devoted to the apparatus for cutting metal. The technology of plasma cutting, as well as the device and features of the equipment are considered