2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:33

The impact of an electric arc on the structure of a material is one of the oldest ways to obtain a strong connection between metal workpieces. The first technological approaches to this welding method had a lot of disadvantages associated with the porosity of the weld and the formation of cracks in the working area. To date, manufacturers of equipment and auxiliary devices have significantly optimized the method of electric arc welding, expanding the scope of its use.

Technology overview

The method is designated MMA (Manual Metal Arc), which can be deciphered as manual stick electrode welding. The workflow is based on the control of electric current supplied to the target area by a special source connected to the network. Current is supplied to the parts to be welded by two cables of different polarity. Actually, the closure of the electrical circuit and provokes the formation of an arc,the thermal effect of which melts the metal and forms a weld pool.

After the end of the heat attack, the working area cools down, and its structure crystallizes. An important component of the technology of electric arc welding is the electrode. As a rule, this is a steel rod provided with a coating with a certain chemical composition. As the electric arc is applied, the structure of the bar also melts and drops into the working area, forming a material with a single structure with the workpiece.

Ignition of the arc as the first working step

As already mentioned, the initiation of thermal exposure occurs as a result of the closing of the electrical circuit. The arc itself, depending on the current source used, can be characterized by gently dipping, steeply dipping, or hard current-voltage properties. It occurs as a result of applying current to the electrode and the surface of the workpiece. Current is passed through both objects, after which an electric arc is formed between them.

The very excitation of the process occurs in different ways. In one case, arc welding is initiated by briefly touching the work piece with a quick breakaway with the bar. And in the other, striking touches are performed with the same separations at certain distances. In this case, the stability of welding will depend precisely on maintaining an acceptable distance between the electrode and the workpiece. If this distance is exceeded, the arc will stop. Conversely, placing the rod too close to the part to be welded can cause sticking of materials. ChoiceThe optimal distance depends on the degree of elasticity of the arc itself, which is also determined by the current-voltage settings of the equipment. Experienced craftsmen can adjust the distance within the allowable range, thus affecting both the efficiency of the melt and the penetration of the metal.

Welding process

The already mentioned current source is involved in the work, the types of which will be considered separately, and two cables with different polarity. One cable ends with an electrode holder, and the other with a terminal clamp, which is fixed on the workpiece. As a result of the thermal effect of the initiated arc, the metal melts in the weld pool. As this process proceeds, the transfer of drops of the consumable electrode is also carried out - small-drop and large-drop. Here it is necessary to emphasize the importance of the bar coating. The chemical composition of the coating is determined not so much by the requirements for interaction with an electric arc, but by the influence on the structure of the seam, which will accept the components of the coating through melting drops.

In the process of electric arc welding, the outer layer of the electrode is also burned, resulting in the formation of gaseous protective compounds. The formation of a cloud that does not allow harmful effects from the environment is the fundamental difference between the modern approach to MMA welding. After the electric arc is stopped, the process of solidification and crystallization of the formed compound begins.

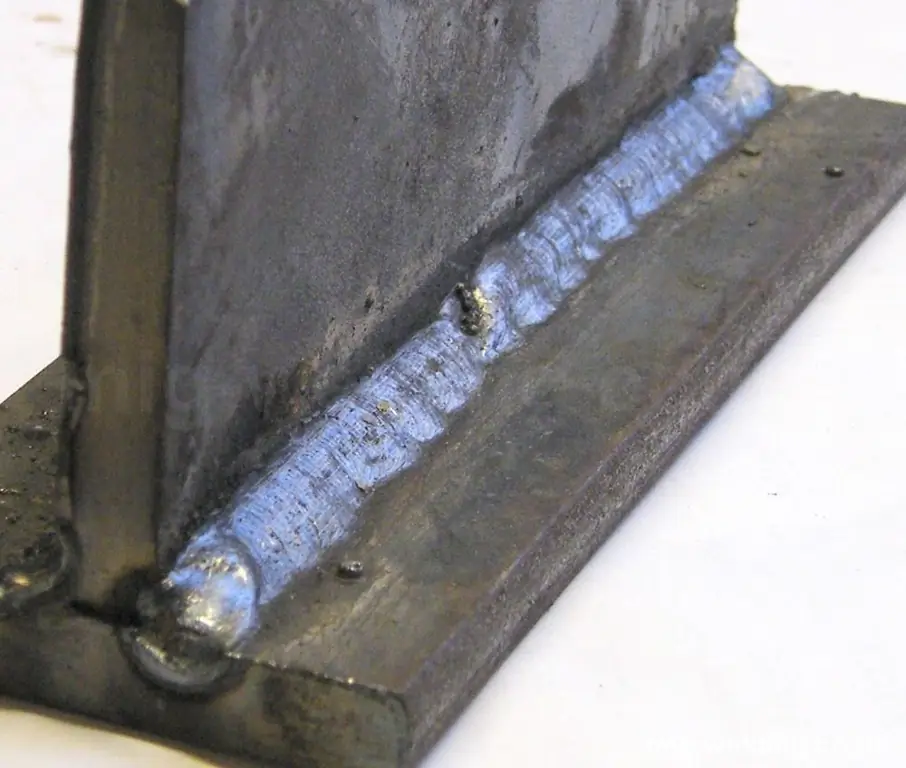

Types of seams produced

There are several classifications of seams that can be obtained in the process of this welding. For example, ceiling, vertical and horizontal connections are distinguished by position. In turn, the vertical seams differ depending on the direction - downhill and uphill. Horizontal joints are perhaps the most difficult, since metal will fall from the welding zone to the lower edges of the workpiece. For the same reason, the top hem may be undercut.

Discontinuous and continuous connections are distinguished by their length. The former are quite often used for the reason that they save resources and time. Solid seams of electric arc welding are used in cases where it is necessary to ensure a high degree of reliability when pairing two critical structures. An intermittent connection is less durable, but in certain conditions it pays off.

There is also a classification by convexity. This parameter depends on the volume of deposited metal. There are convex, normal and concave seams. At the same time, one should not expect that the presence of a large amount of overlay as such ensures the strength and durability of the connection. Under the action of high loads and vibrations, such a seam loses to the joint of a normal structure.

Transformers for MMA welding

This is a universal source and converter of electric current, which is also used in flux welding and plasma cutting of metal. Such devices are simple in design, unpretentious in maintenance and reliable. Management evenmodern models are mostly mechanical. The stuffing of the equipment is a coil with a wound wire - a core that converts the mains electric current into the voltage necessary for specific tasks. It is important to note that working with electric arc welding under transformer power supply involves the use of alternating current, which requires professional skills from the operator.

Inverter devices

The most technologically advanced, easy to use and functional device to support modern welding. It provides operation in DC conditions, increasing the chances of getting a smooth and clean seam even for a beginner. More importantly, electric arc welding with an inverter allows you to use a household network for power if it is capable of providing current from 16 A to 25 A. In general, this is the best solution for private needs when it is necessary to process parts in a garage, lay metal coatings, etc. e. Specialists can also use inverter resources for argon-arc welding, expanding the possibilities of equipment operation.

Arc Welding Rectifiers

Such devices are used to convert mains current from AC to DC, also contributing to the implementation of high-quality seams. The main difference between this type of current sources is the coherence of interaction with different types of electrodes. With this support, arc welding machines can be used for operations in protective gas environments - for example, if the rod is made of steel ornon-ferrous metal. The disadvantages of rectifiers include large size, large mass and, as a result, difficulties with transportation. Therefore, manufacturers, as an addition, offer running platforms with wheels for convenient movement of the device.

Pros of technology

The configuration of this welding method against the background of many alternative methods may seem outdated and inefficient, however, within the framework of this concept, it is possible to organize the possibility of processing almost all common types of metals. Versatility is the main advantage of the MMA method. There is also a plus in terms of physical ergonomics of work. This is not to say that manual arc welding is comfortable, but the very ability to perform operations in any position and in confined spaces is very valuable.

Separately, it is worth emphasizing the independence from external atmospheric and temperature conditions of work. The process can be organized both indoors and outdoors. If we are talking about increased requirements for the quality of the weld, then the technology allows the use of protective media to prevent air from entering the weld pool, which minimizes the risk of defects.

Cons of technology

The method is very cheap in terms of organization, which cannot but cause a number of negative factors. For example, the exclusion of modern methods of process automation and electronic control of individual parameters of the power source shifts the responsibility for the quality of the seam to the operator. From his skillsthe characteristics of the resulting structure of the compound will depend to a greater extent. Simple in execution, electric arc welding of metals cannot be called either. The difficulty lies in the process of ignition of the arc, which, again, is controlled by the user "by eye" without auxiliary systems. If we compare the method with semi-automatic welding, then there will be a lack of productivity.

Conclusion

Due to its versatility, MMA technology has embraced and consistently holds many applications. In the household, in workshops and car services, in industries and in construction, electric arc welding finds its place, allowing you to perform a variety of seams. As for the limitations, they are mainly determined by ergonomics. Alternative concepts for semi-automatic welding, due to their convenience, are also in great demand, in some areas displacing the principles of MMA. On the other hand, arc welding outperforms many competitive technologies due to the increased strength of the formed seam and minimal resource investment in the organization of work.

Recommended:

Welding arc temperature: description, arc length and conditions for its appearance

Today, welding is a process that is used quite often when it is necessary to connect two metal parts together. However, few people understand exactly how welding works, as well as what is the temperature of the welding arc and what causes it

Welding of ultrasonic plastics, plastics, metals, polymeric materials, aluminum profiles. Ultrasonic welding: technology, harmful factors

Ultrasonic welding of metals is a process during which a permanent joint is obtained in the solid phase. The formation of juvenile areas (in which bonds are formed) and the contact between them occur under the influence of a special tool

Technology of manual arc welding

Technology of manual arc welding. Features of the application of the welding process and the principles of its operation. Advantages and disadvantages of the welding process with a consumable arc electrode. types of manual arc welding and methods of its application. Parameters affecting the quality of the weld. Safe Welding Practices

Thermite welding: technology. The practice of thermite welding in everyday life and in the electrical industry

The article is devoted to thermite welding technology. The features of this method, the equipment used, the nuances of use, etc. are considered

Arc welding in shielding gas: description of technology, modes, methods

Gas shielded arc welding is a method that significantly improves the quality of the work result. This technology has a number of features. Before applying it, the master must familiarize himself with the basics of arc welding, which is carried out in a shielding gas environment. The features of this technology will be discussed in the article