2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:35

The technological support of modern industrial enterprises is being actively modernized, as a result of which the efficiency of work processes is also improving. This also applies to the methods of processing metal blanks, among which thermal, hydroabrasive and laser can be distinguished. However, the metalworking machine remains in demand, which has many advantages over the mentioned and, of course, more technological units. Firstly, such machines are cheaper in cost, and secondly, they provide a fairly high quality of processing, which in most cases suits customers.

Key features of the lathe

In technical terms, the machine is a complex multi-component machine, the efficiency of which is primarily determined by the power plant. In particular, the sphere where a metalworking machine can be used with its level of productivity also depends on the power. For example, models with a potential of 400 W can be classified as household. These are mini-sets used in the processing of structural elements, metal cladding materials, correction of parts of tools, etc. Semi-professional models already have a power of about 750 watts.

High-performance metalworking machine, which is designed for use in industry, can provide output at the level of 7500 watts. An important characteristic is the distance between the individual tanks of the machine, that is, the technology centers. This parameter determines which blanks the unit will work with.

Varieties of equipment

Both in industry and in households, different types of machines of this family can be used. For example, a milling turning unit combines the functions of a cutter, boring, and also implements countersinking and grooving operations. It is important to note that the organization of the system for switching between processing modes is clearly regulated by GOST. Metalworking machines capable of performing several functions, in accordance with the regulations, when switching to one of the modes, must completely turn off the nodes that are not involved in a particular operation.

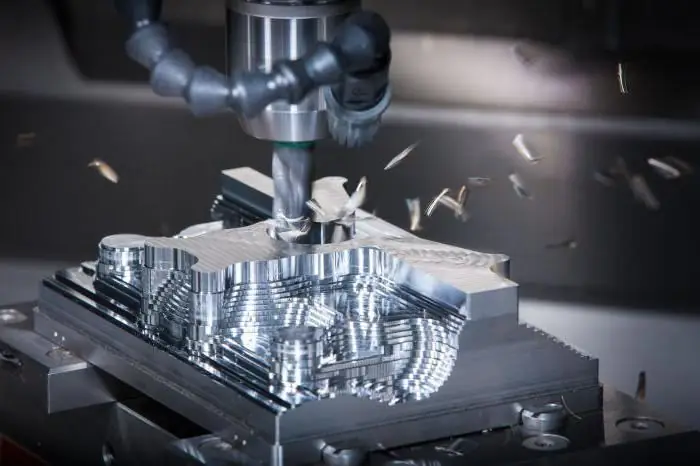

Another type of machine is the screw-cutting model. It can be attributed to highly specialized installations due to the focus on performing a small range of operations. In particular, such machines mainly realize thread forming and turning. Also, the units differ in the type of control. Today, CNC metalworking machines are increasingly being used, the features of which include the ability to operate in accordance with the parameters laid down in the computer program.processing.

Additional accessories

The design of the machine may not always provide for elements that will be effective during operation in all cases. Therefore, some hardware components are optional. These include various tool holders, stands, positioning tools, etc. It is the fixing devices that are most in demand. Thanks to such devices, metalworking lathes stably realize their function, regardless of the shape of the workpiece being processed. But clamps and tool holders should not be confused with positioning components. The task of such accessories is not to mechanically hold the tooling, but to increase the accuracy of its position relative to the working elements of the machine.

Machine Tool Manufacturers

It will not be difficult for an interested builder, material manufacturer or do-it-yourselfer to find a suitable machine in the domestic market. Imported models are offered by companies such as Jet, Proma, Sturm, Stalex, etc. These are high-tech, efficient and reliable units, which also use modern control and management systems. The production of metalworking machine tools in Russia is also at a high level. According to some reports, more than 50 enterprises are engaged in the manufacture of turning units in the country. Advanced domestic products in this segment can be found under the brands Zubr,Corvette, Caliber, etc.

Machine safety

First of all, the operator must take care of his own safety. The equipment usually includes a protective robe, a mask or goggles, closed shoes and a special headgear. It is important to note that the requirements for metalworking machines prohibit working with gloves. A separate group of requirements relates to the selection of equipment. Operations should only be performed using an optimally sharpened tool, which must also be securely fixed in chucks and centered.

If we are talking about a processing technique that involves the use of an improvised tool, then, for example, a chisel should be held with both hands. Each time a workflow starts, a so-called rough run must be performed. The fact is that the safety of metalworking machines is largely determined by the readiness of the equipment to work at peak capacities. Verification processing will allow you to evaluate this ability of equipment at a particular point in time of operation without the risk of causing irreparable harm to the workpiece.

Conclusion

Although turning models of processing machines are considered morally obsolete, manufacturers strive to maintain their performance at a high level. In addition, a modern metalworking machine of this type is equipped with an electronic programmable filling, which also increases its technological level. The very principle of machining remains the same, which has its ownpros and cons. For example, the fact that, in addition to cutting components, the machine does not require the introduction of additional materials during processing, is a definite plus. But in terms of cutting accuracy, such models still cannot compete with machines that implement laser or waterjet processing principles.

Recommended:

Automatic lathe and its characteristics. Automatic lathe multi-spindle longitudinal turning with CNC. Manufacturing and processing of parts on automatic lathes

Automatic lathe is a modern equipment used mainly in mass production of parts. There are many varieties of such machines. One of the most popular types are longitudinal turning lathes

Household metal lathe: types, description

Household lathe: overview, specifications, manufacturers, features. Desktop lathe: description, varieties, operation, photo

Stamping is a metalworking process. Types of stamping and equipment

The technological process in which workpieces are processed, which makes it possible to obtain flat or voluminous finished products of various shapes and sizes, is stamping. The working tool for this purpose is a stamp, which is fixed on a press or other equipment. Stamping is two types of technology that, depending on the conditions, are performed in a hot or cold way, and therefore both equipment and technological standards differ from each other

CNC machines for metalworking: overview, specifications, types and reviews

CNC machines for metalworking are used in almost every machine-building, pipe, repair plant. Modern cutting methods are intensive. The control systems are based on one service center, which is able to monitor the status of the working axes and the surrounding automation in real time. LCD screens provide information in a convenient 3D graphical format

Metal cutting with plasma. Metalworking equipment

When buying a plasma cutter, you should always prioritize quality. Beware of the temptation to buy a cheap low-quality device, as its rapid wear and tear in the long run will lead to much higher costs